I have good mid range power, just a tiny flat spot just before the PV opens, I have rejetted, there is currently no slack in my power valve operation, though I expect it after I remove the shims from the governor assembly. I am running 1 base gasket (this gave me proper squish clearance), currently have approx 10 hours on wossner piston, running a 40 pilot, 2 turns out on the air screw, N1EG needle 2nd clip from top, and a 178 main jet (contrary to my sig) on the standard slide, i have inspected the reeds they are in good condition, am running a new BR8EG spark plug, my CDI failed so I fitted a RM125 CDI, I have adjusted the stator baseplate to 5 degrees BTDC to suit the RM ignition curve, I have fitted a high output ktm HT coil, I am running 32:1 motul 510 with 5% ZX1 friction reducer added to the oil (not the mix), unfortunately my exhaust baffle tube broke so am currently running a hollow silencer, I will be purchasing either a FMF silencer for ?120 (approx) or a DEP silencer for ?90 (approx) shortly after the festive season, I am wearing black boxer shorts with a single white pinstripe across the elastic and with 3 buttons allowing ease of access to the genitals without removal of aforementioned undergarments, my socks are a mismatched pair, 1 'le coq sportif' and 1 'umbro' though they are both white, i am wearing 'lonsdale' trainers in a UK size 9, my shirt is black... if you require any more information to answer the questions listed below;

1 - do I remove all of the shims for more mid power??

2 - to adjust the free play after, do I use the bolt on the left, or the nut on the right?

please, by any means, ask away...

So question 1, the shims, what results have people had by removing different shims, most posts seems to suggest removal of all the shims, and I have found a post stating that each 0.1mm = 100 revs on the engine, parts '16' are 0.5mm and part '15' is 0.2mm, indicating a 1200rpm earlier opening time, is this too much?

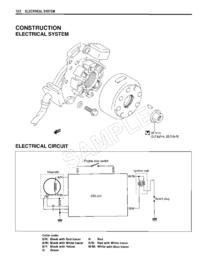

Question 2, do I use nut 3 or bolt 5 to adjust the free play, as there seems to be reports of people doing it on either, obviously it would be preferable to use the bolt as this is a thicker diameter thread than the nut (less chance of breakage), though it appears bolt 5 is situated on splines, thus making adjustment for 0.010" (0.254mm) less accurate?

Another reason I ask is due to this photo existing,

Most people seem to mention adjusting 'free play' on the bell crank, this would be the nut on the other side to what is pointed on this picture.

Also, according to the fiche, the shims should be the other side of the spring, not that it should matter, but why are this guys shims on the other side?