Well being I just cut my squish on my 05 ec 200 I thought I would share a way to flat plate your head so you do not have to install it ever time you make a cut. This will save you a lot of extra work unless you have a computer program.

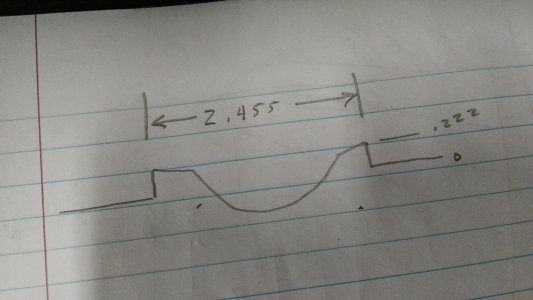

What I did was to make up a spacer ring approx 1/2mm taller than the step on the head and I made it so it was a slip fit over the head edge. See pics.

Then just grease both sides of it and flat plate as usual. I did a installed CC and then flat plated it to find the difference between installed and flat plate. In my case flat plate was 3.5cc more than installed. So I knew when I cut my head I has to add 3.5cc more for my finished cc volume.

I checked this twice while cutting my head between installed and flat plate and the worse it was ever off was 1/10 of a cc. I made mine out of plastic because that is what I had here but I would use aluminum if I was building another one.

Also make sure you make the OD of the ring big enough to get a screw drive under it as the slip fit with grease on it makes it stick very well.

What I did was to make up a spacer ring approx 1/2mm taller than the step on the head and I made it so it was a slip fit over the head edge. See pics.

Then just grease both sides of it and flat plate as usual. I did a installed CC and then flat plated it to find the difference between installed and flat plate. In my case flat plate was 3.5cc more than installed. So I knew when I cut my head I has to add 3.5cc more for my finished cc volume.

I checked this twice while cutting my head between installed and flat plate and the worse it was ever off was 1/10 of a cc. I made mine out of plastic because that is what I had here but I would use aluminum if I was building another one.

Also make sure you make the OD of the ring big enough to get a screw drive under it as the slip fit with grease on it makes it stick very well.