Buy a 12 spanner, with both open end and ring end and make a special tool out of it.

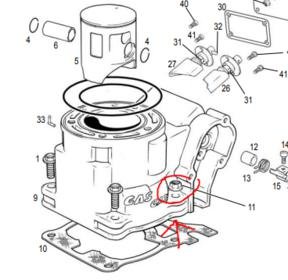

Grind the outer ring thinner so it can fit on the nut.

Grind the open end of the spanner a bit wider, rougly to 12.7-13mm, so it can fit snugly on the 1/2" square socket attachment on the torque wrench.

Go to playstore and download TORQUE WRENCH EXTENSION CALCULATOR

attach spanner to wrench so they form a straight line

Measure and input two lengths desired by program (metric, imperial doesnt matter)

Input desired torque value for the nut (metric, imperial, doesnt matter)

Program will calculate new value for torque setting of the wrench, since extended wrench needs to apply less torque, but the actual torque on the nut will be correct

Never fully torque one side only, just because you can. Sth can break, bend, misshape..