mountain thumper

New member

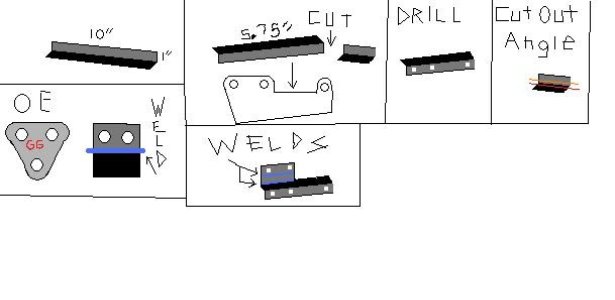

just finished my diy xr chain guide adapter!

took me 2 hours and all the material i used was about 10 inches of 1" angle iron.

simple plan was

1take xr adapter, remove puck/mounting bolts.

2place angle iron over mounting bolt holes, with the angle going inside, over the top.

mark the ends, cut and save.

3then, place iron back on xr guide, mark hole locations and drill.

bolt the iron to the mount, you will notice the sprocket slot is blocked p3

4 cut off the portion in the way (i just eyeballed it till i have a chance to clean and paint)

5 take the piece that was cut off original length, and cut it into two peices, down the middle at the angle=2 pc flat iron.

6use gg chain guide as a template to mark holes on one peice of the flat iron, and cut to mount width on swingarm.

7 now take another piece of flat, and make an identical piece as in step 6, but dont drill holes.

8 weld p6 and p7 together butt to butt.

9place p3 onto chain, and bolt p6/7 to swingarm.

10 mark where the two meet, remove all parts

11 weld parts 6/7 to part 3, with the bolt holes vertically inline. weld to the edge along xr guide centerline.

obviously theres a little finangling to get a perfect fit, but this was a $2 (already had xr guide) alternative to the ltr kit which is $65 (sorry ltr guys, just couldnt afford it)

at this moment its all raw steel, and rough, but once ive cleaned up the welds, rounded the edges and painted it, ill post pics.

took me 2 hours and all the material i used was about 10 inches of 1" angle iron.

simple plan was

1take xr adapter, remove puck/mounting bolts.

2place angle iron over mounting bolt holes, with the angle going inside, over the top.

mark the ends, cut and save.

3then, place iron back on xr guide, mark hole locations and drill.

bolt the iron to the mount, you will notice the sprocket slot is blocked p3

4 cut off the portion in the way (i just eyeballed it till i have a chance to clean and paint)

5 take the piece that was cut off original length, and cut it into two peices, down the middle at the angle=2 pc flat iron.

6use gg chain guide as a template to mark holes on one peice of the flat iron, and cut to mount width on swingarm.

7 now take another piece of flat, and make an identical piece as in step 6, but dont drill holes.

8 weld p6 and p7 together butt to butt.

9place p3 onto chain, and bolt p6/7 to swingarm.

10 mark where the two meet, remove all parts

11 weld parts 6/7 to part 3, with the bolt holes vertically inline. weld to the edge along xr guide centerline.

obviously theres a little finangling to get a perfect fit, but this was a $2 (already had xr guide) alternative to the ltr kit which is $65 (sorry ltr guys, just couldnt afford it)

at this moment its all raw steel, and rough, but once ive cleaned up the welds, rounded the edges and painted it, ill post pics.

Last edited: