savage sausage

New member

5. I also did some work with the Inlet tract as it was really mishapen and uneven from the factory.

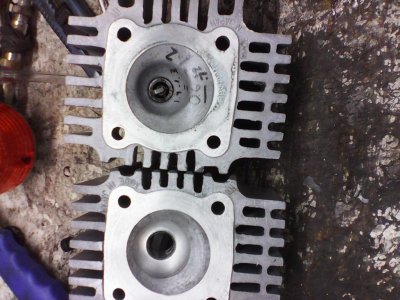

Before

After

6. The finished result

The Boost Port is some sort of a decent shape now

and finally the case as a whole

A bit of effort and time has produced something better than the original, I can guarantee the fuel will now flow better which will make a more efficient engine.

Even if it only makes 0.001% HP improvement then i'm happy with that

maybe my marketing tag line needs to change.

"Savage Sausage Racing Developments - +50Bhp Increase - Satisfaction Guaranteed"

(probably said in an american accent for better sales)

Before

After

6. The finished result

The Boost Port is some sort of a decent shape now

and finally the case as a whole

A bit of effort and time has produced something better than the original, I can guarantee the fuel will now flow better which will make a more efficient engine.

Even if it only makes 0.001% HP improvement then i'm happy with that

maybe my marketing tag line needs to change.

"Savage Sausage Racing Developments - +50Bhp Increase - Satisfaction Guaranteed"

(probably said in an american accent for better sales)