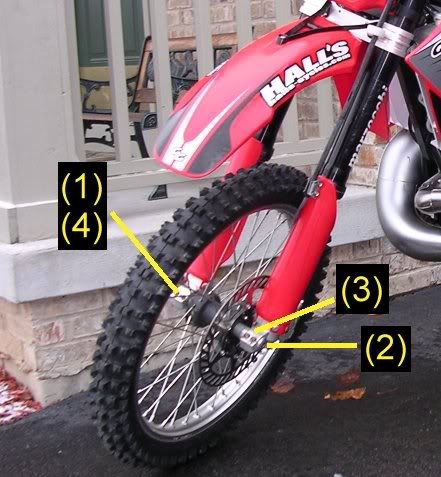

What's the trick to bolting the front wheel back on and not binding the forks?

I changed the oil and seals on my 07, and after bolting the wheel back up the fork action is not as smooth. All the adjusters are set at full soft.

Binding might be too strong a word to use, but can't think of another that fits.

Separately, off the bike both forks worked smooth after the oil change.

Is there a procedure as to which axle pinch clamp is tightened first? Ive repeated the wheel install procedure a couple of times. I can reduce the binding somewhat. Can the triple clamp effect the binding of the forks? I don't have a torque wrench yet, so I used a 1/4 drive ratchet to keep the torque to a minimum.

I changed the oil and seals on my 07, and after bolting the wheel back up the fork action is not as smooth. All the adjusters are set at full soft.

Binding might be too strong a word to use, but can't think of another that fits.

Separately, off the bike both forks worked smooth after the oil change.

Is there a procedure as to which axle pinch clamp is tightened first? Ive repeated the wheel install procedure a couple of times. I can reduce the binding somewhat. Can the triple clamp effect the binding of the forks? I don't have a torque wrench yet, so I used a 1/4 drive ratchet to keep the torque to a minimum.