noobi

New member

ok, after all the query threads, it is going to happen.

i will replace the piston and ring on my bike!!!

i got a piston set ok, wiseco make one, same as the cr125gp 54mm

while im at it will may do some port matching, squish seting and general maintenence on the engine while the barrel is off.

who make the gg little end bearings? i can get a genuine one but at twice the price of any other sort of needle roller bearing,

now if anyone has any info they would like to pass on to me, i have never done this before, that would be greatly appreciated. i have access to all the necessary tools.

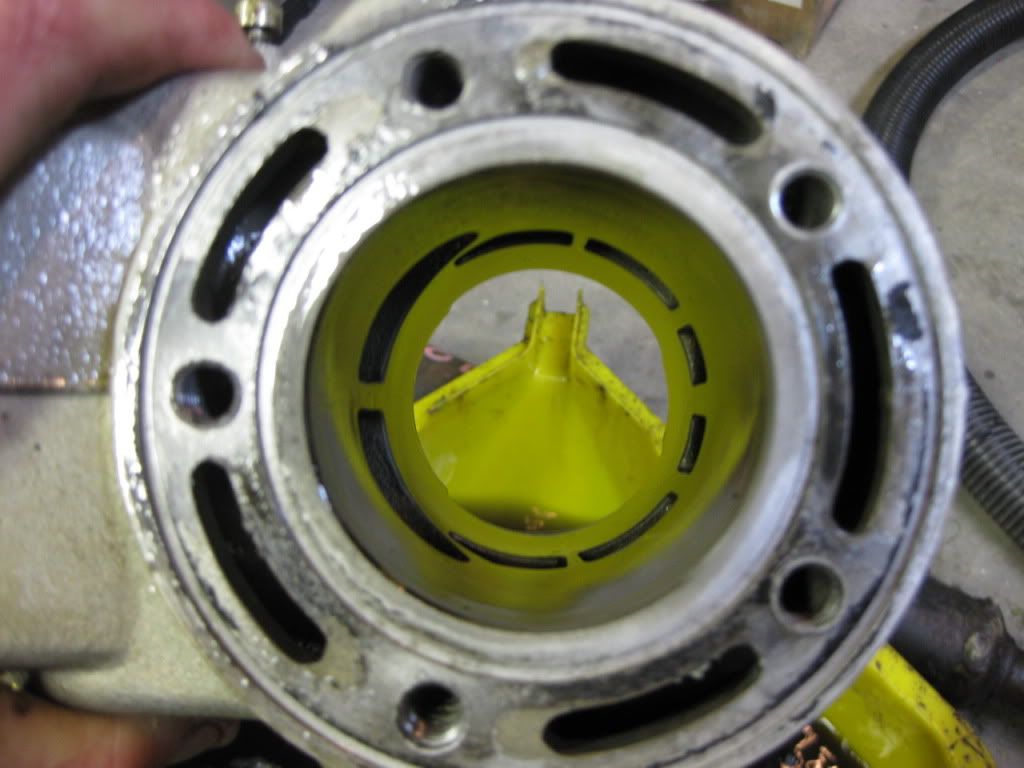

i have started this as more of a journel for me, as there is no other threads about it. i will post photos too

so before i start, any helpful tips anyone

thanks

i will replace the piston and ring on my bike!!!

i got a piston set ok, wiseco make one, same as the cr125gp 54mm

while im at it will may do some port matching, squish seting and general maintenence on the engine while the barrel is off.

who make the gg little end bearings? i can get a genuine one but at twice the price of any other sort of needle roller bearing,

now if anyone has any info they would like to pass on to me, i have never done this before, that would be greatly appreciated. i have access to all the necessary tools.

i have started this as more of a journel for me, as there is no other threads about it. i will post photos too

so before i start, any helpful tips anyone

thanks