You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2007 EC300 loose engine

- Thread starter Col

- Start date

Davehuge

Member

Hi Col

No there isn't anything that goes inside the engine cases.

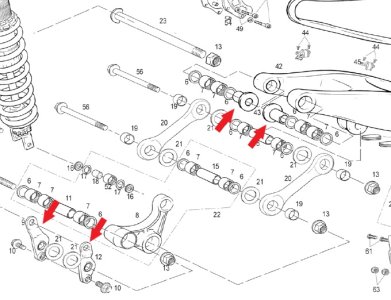

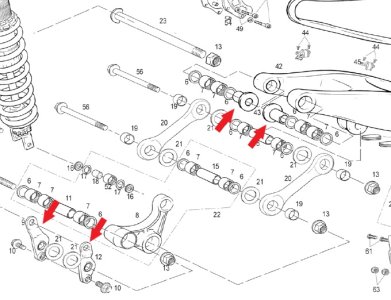

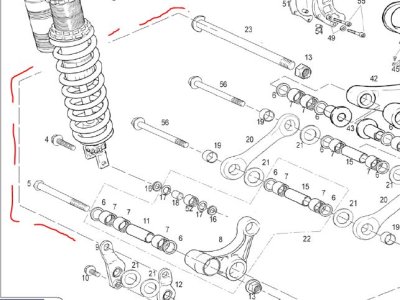

See the attached image taken from the Parts List, I've arrowed the two 'Swingarm Bushing' part 43, I think that's the part you mentioned. Are these fitted correctly?

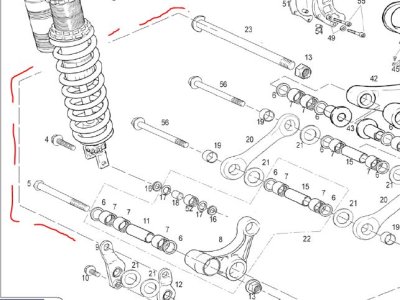

What about the the other parts I've arrowed, part 9 'Right Rocker Arm Support' and part 12 'Left Rocker Arm Support'. Are these fitted correctly? The swinging arm pivot bolt passes through these. See the dotted line I've marked on the 2nd picture.

It should be a snug fit when you push the swinging arm into place, with maybe just a bit of movement, then once you tighten the swinging arm pivot bolt to the specified torque, the play should disappear with no movement possible of the engine and no sideways movement of the swinging arm. The swinging arm should pivot nice and smoothly on it's bearings as if the suspension was moving.

All the best, Dave.

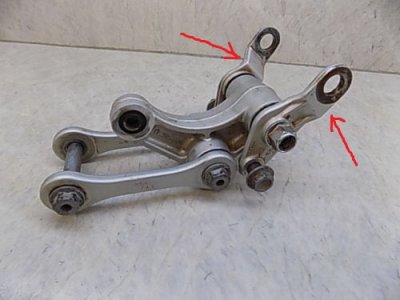

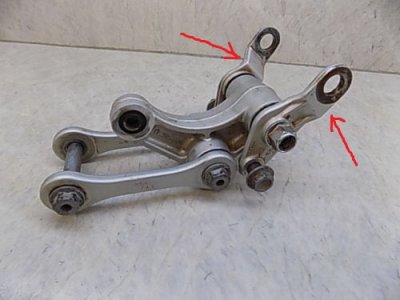

Here's a photo with the Right and Left Rocker Arm Supports arrowed. These also act as spacers, so if they're not in place you will have too much play.

No there isn't anything that goes inside the engine cases.

See the attached image taken from the Parts List, I've arrowed the two 'Swingarm Bushing' part 43, I think that's the part you mentioned. Are these fitted correctly?

What about the the other parts I've arrowed, part 9 'Right Rocker Arm Support' and part 12 'Left Rocker Arm Support'. Are these fitted correctly? The swinging arm pivot bolt passes through these. See the dotted line I've marked on the 2nd picture.

It should be a snug fit when you push the swinging arm into place, with maybe just a bit of movement, then once you tighten the swinging arm pivot bolt to the specified torque, the play should disappear with no movement possible of the engine and no sideways movement of the swinging arm. The swinging arm should pivot nice and smoothly on it's bearings as if the suspension was moving.

All the best, Dave.

Here's a photo with the Right and Left Rocker Arm Supports arrowed. These also act as spacers, so if they're not in place you will have too much play.

Last edited:

Zman

Platinum Level Site Supporter

Is it possible that you do not have the original engine or frame? The bikes before 2000 or 2001 had engines and frames that used a smaller diameter swing arm axle. I also heard the bottom engine mount was relocated after 2006.

I put a 2004 engine in a 2000 frame one time and needed to machine some aluminum inserts to put into the engine case to take up the gap for the smaller swingarm pivot shaft. I found that a Maglite AA flash had a correct interior diameter for the shaft but the outside needed to have a little material removed to fit in the cases.

I guess it is also possible that if the bike was ridden with a loose swing arm shaft that it could wear the engine cases and make them a loose.

I put a 2004 engine in a 2000 frame one time and needed to machine some aluminum inserts to put into the engine case to take up the gap for the smaller swingarm pivot shaft. I found that a Maglite AA flash had a correct interior diameter for the shaft but the outside needed to have a little material removed to fit in the cases.

I guess it is also possible that if the bike was ridden with a loose swing arm shaft that it could wear the engine cases and make them a loose.

The rocker arm supports previously mentioned have a habit of wearing out on high mileage/hour bikes. I've had to buy several replacements over the years.

You definitely want to solve this problem before running the bike any further. I have an engine that actually has a wear hole in it because these were not replaced in time.

You definitely want to solve this problem before running the bike any further. I have an engine that actually has a wear hole in it because these were not replaced in time.

Davehuge

Member

The rocker arm supports previously mentioned have a habit of wearing out on high mileage/hour bikes.

That's interesting to know and something to look out for, although I don't understand why it would wear? Once the swinging arm pivot bolt is tightened up there shouldn't be anything moving or rubbing to make them wear. Which part of the rocker arm support was worn?

How are you getting on Col? Let us know.

Thanks very much for the replies, it?s much appreciated.

I seized the bike on a trail ride a few years ago (split hose) and dropped it into a local workshop for a rebuild. He had it 6 months and when it came back the vibration was pretty bad, it came back rusty and with cracked plastics. The guy has since gone out of business I think. I didn?t get a chance to ride it until recently due to other commitments.

I can get a lever and move the engine at the swingarm pivot maybe 10mm. It?s a bit like Zman said, like the hole through the cases is too big.

I?ll strip it down myself this week and see if it matches the parts diagrams, also I?ll try to take a measurement of the hole through the cases.

Thanks again guys, I?ll be back with more questions I?m sure!

I seized the bike on a trail ride a few years ago (split hose) and dropped it into a local workshop for a rebuild. He had it 6 months and when it came back the vibration was pretty bad, it came back rusty and with cracked plastics. The guy has since gone out of business I think. I didn?t get a chance to ride it until recently due to other commitments.

I can get a lever and move the engine at the swingarm pivot maybe 10mm. It?s a bit like Zman said, like the hole through the cases is too big.

I?ll strip it down myself this week and see if it matches the parts diagrams, also I?ll try to take a measurement of the hole through the cases.

Thanks again guys, I?ll be back with more questions I?m sure!

Davehuge

Member

If you can move the engine 10mm then I would say it's not just wear, I reckon there must be something missing and it should be pretty obvious once you get it apart.

Sounds like a terrible workshop, no wonder he went out of business.

What part of the UK are you in?

Best of luck, Dave.

Sounds like a terrible workshop, no wonder he went out of business.

What part of the UK are you in?

Best of luck, Dave.

That's interesting to know and something to look out for, although I don't understand why it would wear? Once the swinging arm pivot bolt is tightened up there shouldn't be anything moving or rubbing to make them wear. Which part of the rocker arm support was worn?

How are you getting on Col? Let us know.

The part of the rocker arm that contacts the engine. I am not sure what caused it to wear either, but it was quite thin when I replaced it. The swing-arm bolt was loose, but I know for sure I torqued it down prior, but who can say. I was constantly tightening the motor mount bolts and breaking head stay bars on that particular bike. My 2011 does not seem to be so bad.

Davehuge

Member

I was constantly tightening the motor mount bolts and breaking head stay bars on that particular bike.

That's interesting, it sounds to me like the frame that was at fault, out of tolerance, wider at the swinging arm pivot than it should have been. So when you torqued the swinging arm pivot it was tightening against the tension of the frame, not against the crankcases.

This would have meant the engine was still free to move about, hence putting strain on the head stay bars, fatiguing them until they snapped.

Anyway, that's my theory!

I finally got time to strip it down.

As feared, it looks like the cases are badly ovalised at the swingarm mount.

But the gap is massive between the bolt and the hole, seems too big to have been caused by a lose bolt and vibration.

I can try to drill the cases back to a round shape and make a sleeve to go in there, the tricky bit will be getting it exactly right so that the other mount points all line up perfectly

Any more thoughts before I do something I?m almost certainly going to regret!

As feared, it looks like the cases are badly ovalised at the swingarm mount.

But the gap is massive between the bolt and the hole, seems too big to have been caused by a lose bolt and vibration.

I can try to drill the cases back to a round shape and make a sleeve to go in there, the tricky bit will be getting it exactly right so that the other mount points all line up perfectly

Any more thoughts before I do something I?m almost certainly going to regret!

Davehuge

Member

Maybe someone's going to shoot me down in flames but in my opinion...

Yes it looks terrible, however I wouldn't worry too much about the excessive clearance around the swinging arm pivot bolt. I don't believe it's the nice tight fit of the pivot bolt in the casing that locks the rear of the engine in place, it's the bushes and spacers, etc. clamping the engine in place when the pivot bolt is tightened to the correct torque.

I would leave the hole as it is. Square off the casing around the hole then rebuild it and add spacers/shims to get a nice snug fit. Then when the pivot bolt is tightened it will clamp the engine, locking it in place.

Anyway, that's what I would try. If it doesn't work then go down the route of boring the casings out (if there's enough meat in them?) and adding a sleeve. If you do end up fitting a sleeve then ensure it's shorter than the hole in the casing, so the engine casings can be clamped. If the sleeve is too long it will just clamp the sleeve leaving the engine loose and causing a similar problem all over again. I hope this make sense!

All the best, Dave.

By the way... I remember reading some models have different diameter pivot bolts. Do you know if this is the original engine that came in the frame? Maybe the engine's been used in a different frame with a larger diameter pivot bolt?

Yes it looks terrible, however I wouldn't worry too much about the excessive clearance around the swinging arm pivot bolt. I don't believe it's the nice tight fit of the pivot bolt in the casing that locks the rear of the engine in place, it's the bushes and spacers, etc. clamping the engine in place when the pivot bolt is tightened to the correct torque.

I would leave the hole as it is. Square off the casing around the hole then rebuild it and add spacers/shims to get a nice snug fit. Then when the pivot bolt is tightened it will clamp the engine, locking it in place.

Anyway, that's what I would try. If it doesn't work then go down the route of boring the casings out (if there's enough meat in them?) and adding a sleeve. If you do end up fitting a sleeve then ensure it's shorter than the hole in the casing, so the engine casings can be clamped. If the sleeve is too long it will just clamp the sleeve leaving the engine loose and causing a similar problem all over again. I hope this make sense!

All the best, Dave.

By the way... I remember reading some models have different diameter pivot bolts. Do you know if this is the original engine that came in the frame? Maybe the engine's been used in a different frame with a larger diameter pivot bolt?

Thanks Dave,

I was wondering whether it?s mainly friction that should be holding it there.

I?ll check all of the spacers & bushes for the swingarm etc against the parts diagrams. At least I got the swingarm bolt out ok, good opportunity to grease everything up etc

I think it’s the original engine, the serial starts 250607 which could correspond to a date, it’s a 2007 bike

I was wondering whether it?s mainly friction that should be holding it there.

I?ll check all of the spacers & bushes for the swingarm etc against the parts diagrams. At least I got the swingarm bolt out ok, good opportunity to grease everything up etc

I think it’s the original engine, the serial starts 250607 which could correspond to a date, it’s a 2007 bike

Well, the swingarm bushes are there and the upper rocker arm support spacers are so I can?t see that anything is missing.

The nut was very stiff on the swingarm pivot bolt, I?m wondering if is was stopping before everything was properly snug and allowing the movement.

I’ll order some new rocker arm support just in case they are worn as mentioned earlier.

Edit: just had a look at those rocker arm supports and they do look very worn, especially on the inside where the engine contacts them.

The nut was very stiff on the swingarm pivot bolt, I?m wondering if is was stopping before everything was properly snug and allowing the movement.

I’ll order some new rocker arm support just in case they are worn as mentioned earlier.

Edit: just had a look at those rocker arm supports and they do look very worn, especially on the inside where the engine contacts them.

Last edited:

Davehuge

Member

The nut was very stiff on the swingarm pivot bolt, I'm wondering if is was stopping before everything was properly snug and allowing the movement.

I?ll order some new rocker arm support just in case they are worn as mentioned earlier.

Well it sounds like you've found out what caused the problem in the first place.

motopsycho87

New member

I haven't read all the posts in this topic, but on both of the ec300s I've owned they have had play on the swingarm bolt, the reason being that the nut tightens on the shoulder of the bolt before it tightens on the frame. The cure, use a couple of washers larger than the largest diameter of the bolt (not the undersized threaded section).

Davehuge

Member

On both of the ec300s I've owned they have had play on the swingarm bolt, the reason being that the nut tightens on the shoulder of the bolt before it tightens on the frame.

That's interesting...

Similar threads

- Replies

- 3

- Views

- 2K