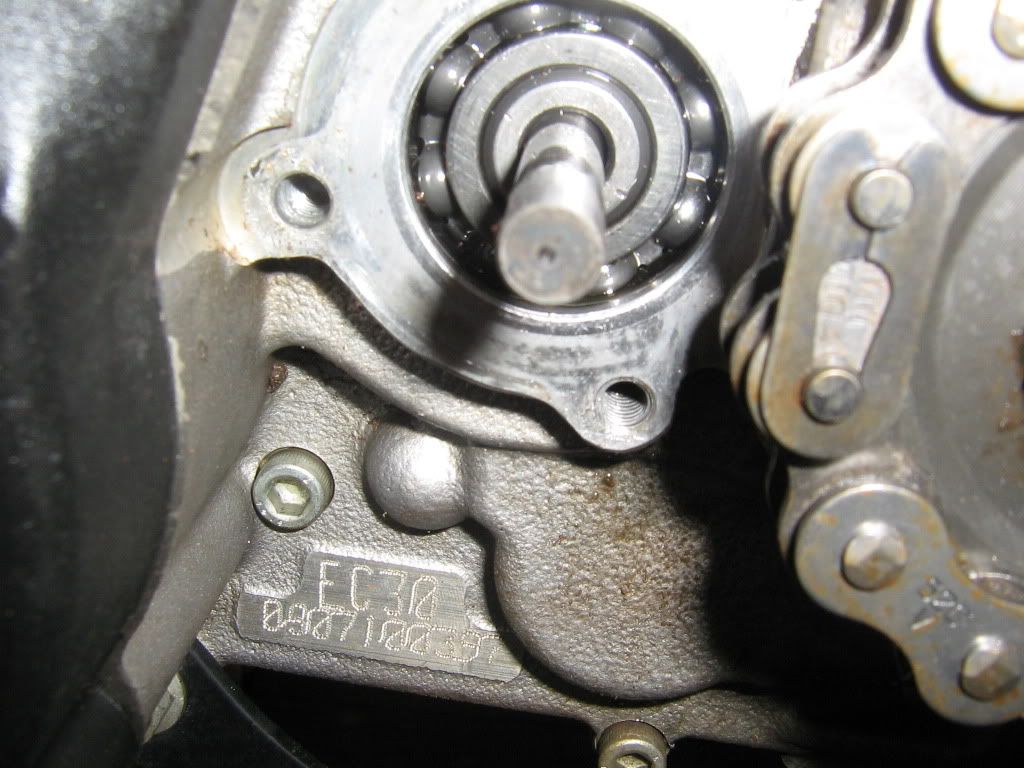

What is the slave cylinder side of the clutch rod supposed to look like? Should it be flat, or does it have a dimple in it? It also looks like it's been heat treated.

The details:

I installed a Revloc DynaRing and I've been working on getting it properly set up. One of the issues I've recently had is that the gap has "magically" decreased over the last couple rides. I couldn't figure it out at first, but after looking at the clutch rod I think I've discovered the problem. I think what's happening is the needle bearing (on the clutch side) was packing up with material and the rod itself was spinning.

Originally I wasn't quite able to create the required minimum 1mm gap using all the shims Revloc provides. Allan has sent me a new part which should take care of that....except now that it appears my clutch rod has effectively "shortened", I again can't create the full gap.

So, assuming the end is supposed to be flat, I'm planning on filling in the dimple with my TIG welder. The new parts from Revloc should allow me to get the full gap, the needle bearing shouldn't pack up with clutch material, and I should be good to go. ...Right?

The details:

I installed a Revloc DynaRing and I've been working on getting it properly set up. One of the issues I've recently had is that the gap has "magically" decreased over the last couple rides. I couldn't figure it out at first, but after looking at the clutch rod I think I've discovered the problem. I think what's happening is the needle bearing (on the clutch side) was packing up with material and the rod itself was spinning.

Originally I wasn't quite able to create the required minimum 1mm gap using all the shims Revloc provides. Allan has sent me a new part which should take care of that....except now that it appears my clutch rod has effectively "shortened", I again can't create the full gap.

So, assuming the end is supposed to be flat, I'm planning on filling in the dimple with my TIG welder. The new parts from Revloc should allow me to get the full gap, the needle bearing shouldn't pack up with clutch material, and I should be good to go. ...Right?