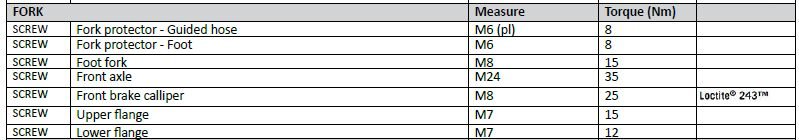

Have my owners manual and found what I think is the upper and lower triple clamp torque specs, but would like to confirm before tightening them down. (See attached). Looking at the Upper and Lower flange torque specs.

I like to loosen and retorque my forks after each ride (drop ) to make sure everything is all aligned up correctly - torque the bolts to the correct torque is also important.

) to make sure everything is all aligned up correctly - torque the bolts to the correct torque is also important.

Also in the manual it says "Link", which I assume is linkage, and all the nuts are at 80nm - This sounds about right, but would like to confirm before bringing down the torque.

I like to loosen and retorque my forks after each ride (drop

Also in the manual it says "Link", which I assume is linkage, and all the nuts are at 80nm - This sounds about right, but would like to confirm before bringing down the torque.