So, no, but I have put Ignitech on several bikes. You could start with CR250 kit that curve would be a good starting point. But you would need to set the base advance first.

This isn't that hard, you just have to engage grey matter to what is going on.

I use a degree wheel on the flywheel held on with a nut and bolt to the flywheel shaft. Put in a piston stop and wind the engine up to there. Read the wheel. Wind it the other way and read the wheel. Let's say you get 280 and 320. Take the stop out and move to the middle at 300 (or whatever). There is TDC accurately.

Put some masking tape on the flywheel near a reference point on case or make a pointer that holds close to flywheel. Then wind it back opposite direction to rotation say 15 degrees. Scribe a line with biro on tape.

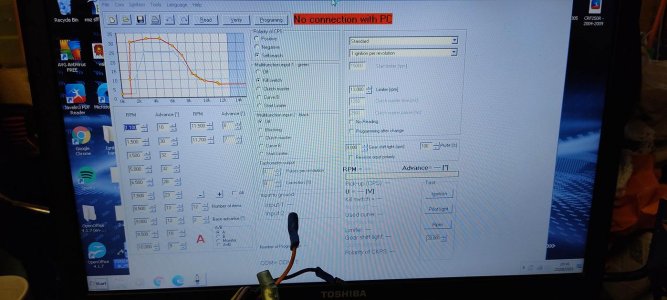

Right, now program a flat 'curve' at 15 degrees. Start the bike. Your timing light should show this line on the masking tape appear probably before or after this reference point. Use the sw to adjust it to line up. This is now firing at 15 degrees before top dead centre.

Save this number as your base advance for all future curves.

Pull in CR curve, set base advance and that's your starting point.

Most curves should end peak power at 15deg but with a heap more below peak. Listening for any hint of detonation at any throttle position and estimate the revs or ideally squeeze a road tyre on and visit the dyno.