Ok, I'm in the process of total rebuild on my '05 MC 250. Right main bearing went...

So during disassembly I measured how my piston aligned with exhaust port. Top of piston .83mm above bottom of exhaust port. One .3mm base gasket. One might conclude they dropped the cyl. to increase compression on the MC. The parts fiche also shows a different head for the MC.

So based on the conventional wisdom expounded on this site I mentioned to the engine guy pressing my crank that I was gonna raise my cyl. To align the exhaust port and would likely need squish band correction.

Well... He said (emphatically) that aligning top of piston to bottom of exhaust port is WRONG... that piston should be aligned to bottom of transfer ports. Basically said bottom of exhaust port is irrelevant... He also mentioned that IF the piston is high on the transfer ports, correcting that will give me more top end... I got plenty of that now I just want a 'crisper' low to mid.

I just want a 'crisper' low to mid.

My questions:

- I didn't check piston related to transfer ports (and cyl. is at machinists presently) but why is the talk here about exhaust port and not transfers? Maybe bottom of trans and ex is equivalent on these motors?

- If all I'm worried about is low-mid grunt is there anything to be gained by messing with altering port timing via base gaskets? The way I understand it one would actually want to lower the cyl. to move timing towards more favorable low end...

- I will definitely get the squish corrected once this is back together so maybe that's sufficient?

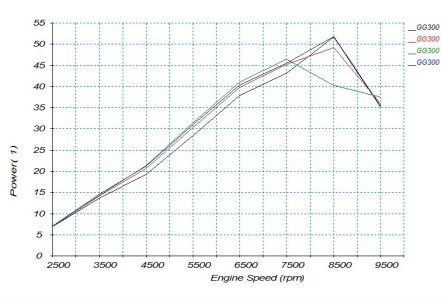

- Does this sound like I'd maybe like a 300?

So during disassembly I measured how my piston aligned with exhaust port. Top of piston .83mm above bottom of exhaust port. One .3mm base gasket. One might conclude they dropped the cyl. to increase compression on the MC. The parts fiche also shows a different head for the MC.

So based on the conventional wisdom expounded on this site I mentioned to the engine guy pressing my crank that I was gonna raise my cyl. To align the exhaust port and would likely need squish band correction.

Well... He said (emphatically) that aligning top of piston to bottom of exhaust port is WRONG... that piston should be aligned to bottom of transfer ports. Basically said bottom of exhaust port is irrelevant... He also mentioned that IF the piston is high on the transfer ports, correcting that will give me more top end... I got plenty of that now

My questions:

- I didn't check piston related to transfer ports (and cyl. is at machinists presently) but why is the talk here about exhaust port and not transfers? Maybe bottom of trans and ex is equivalent on these motors?

- If all I'm worried about is low-mid grunt is there anything to be gained by messing with altering port timing via base gaskets? The way I understand it one would actually want to lower the cyl. to move timing towards more favorable low end...

- I will definitely get the squish corrected once this is back together so maybe that's sufficient?

- Does this sound like I'd maybe like a 300?