Hello all!

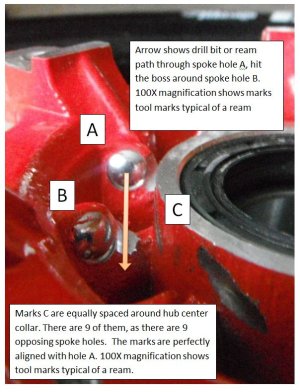

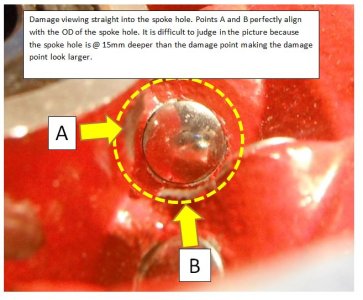

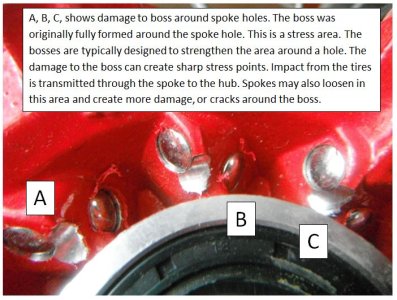

Hope all goes well and thanks in advance for reading and posting. I recently picked up a GG wheel set that was reported to be brand new. The seller has a good rating and has yet to reply, so I am only posting for thoughts from the group before I go into full attack mode. The seller told me he sent this set to Rad Mfg because they wanted to measure the hubs so they could start making Rad Hubs for GG. He said they look to have been never mounted, unused other than the measurement by Rad. The box had Rad Mfg tape on it, so I assume the story is correct. I got the wheel today and I am freaked out by what looks to be a butcher job on the hubs where someone may have drilled out the OEM spoke holes to put in larger spokes. It?s as if they drilled from the inside of the hub, and as the drill pushed through they kept going and then put deep gouges into the outside of the hub where the drill touched the surface. POOR WORKMANSHIP! Some new spokes have the larger diameter at the base; it?s only a guess at why someone would do this to these hubs! Sorry if this all seems disjointed I am so pissed I can hardly type! I hope it?s just me over reacting!

I have heard of some weird stuff going on at the GG factory between model changes and want to see if anyone has seen something like this. Whatever it is it looks like a hack job, and I am worried that the structural integrity of the hub has been compromised. Especially the way the material is drilled out near the spoke hole and around the outside of the bearing area. This is a major stress point in the hub, lots of shock and transfer and the gouges create stress risers, which lead to cracks, which lead to a VERY BAD DAY in the woods! I hope the pictures do it justice. I will post more if needed. AAAARRRRGGGGGG!

Thanks for any thoughts and help!

Mike

Hope all goes well and thanks in advance for reading and posting. I recently picked up a GG wheel set that was reported to be brand new. The seller has a good rating and has yet to reply, so I am only posting for thoughts from the group before I go into full attack mode. The seller told me he sent this set to Rad Mfg because they wanted to measure the hubs so they could start making Rad Hubs for GG. He said they look to have been never mounted, unused other than the measurement by Rad. The box had Rad Mfg tape on it, so I assume the story is correct. I got the wheel today and I am freaked out by what looks to be a butcher job on the hubs where someone may have drilled out the OEM spoke holes to put in larger spokes. It?s as if they drilled from the inside of the hub, and as the drill pushed through they kept going and then put deep gouges into the outside of the hub where the drill touched the surface. POOR WORKMANSHIP! Some new spokes have the larger diameter at the base; it?s only a guess at why someone would do this to these hubs! Sorry if this all seems disjointed I am so pissed I can hardly type! I hope it?s just me over reacting!

I have heard of some weird stuff going on at the GG factory between model changes and want to see if anyone has seen something like this. Whatever it is it looks like a hack job, and I am worried that the structural integrity of the hub has been compromised. Especially the way the material is drilled out near the spoke hole and around the outside of the bearing area. This is a major stress point in the hub, lots of shock and transfer and the gouges create stress risers, which lead to cracks, which lead to a VERY BAD DAY in the woods! I hope the pictures do it justice. I will post more if needed. AAAARRRRGGGGGG!

Thanks for any thoughts and help!

Mike