For what it's worth, here's what I was told as I ordered my S3 kit:

-The shape, and volume of all 3 inserts combustion chambers are identical, except for the depth they reach down into the cylinder (affecting both squish, and compression ratio.

I can't confirm this, but I CAN tell you that the squish is reduced with each step to higher compression, and otherwise they look the same.

If your a perfectionist, and want to achieve 1mm of squish, you would need to have some work done to balance squish, and comp ratio on the S3. Additionally, if you cannot use the higher comp inserts due to elevation your probably going to be close to OEM squish measurement. (mine was over 2mm in stock form). At this point, you may as well just send out your OEM head for machining, to achieve what your looking for.

If however 1.5mm or so is acceptable to you, the S3 will work great. I have zero complaints, and my 300 runs noticeably stronger than stock with the "AA" insert at 3000 feet +. I also feel it runs cooler, but there's too many variables to be sure.

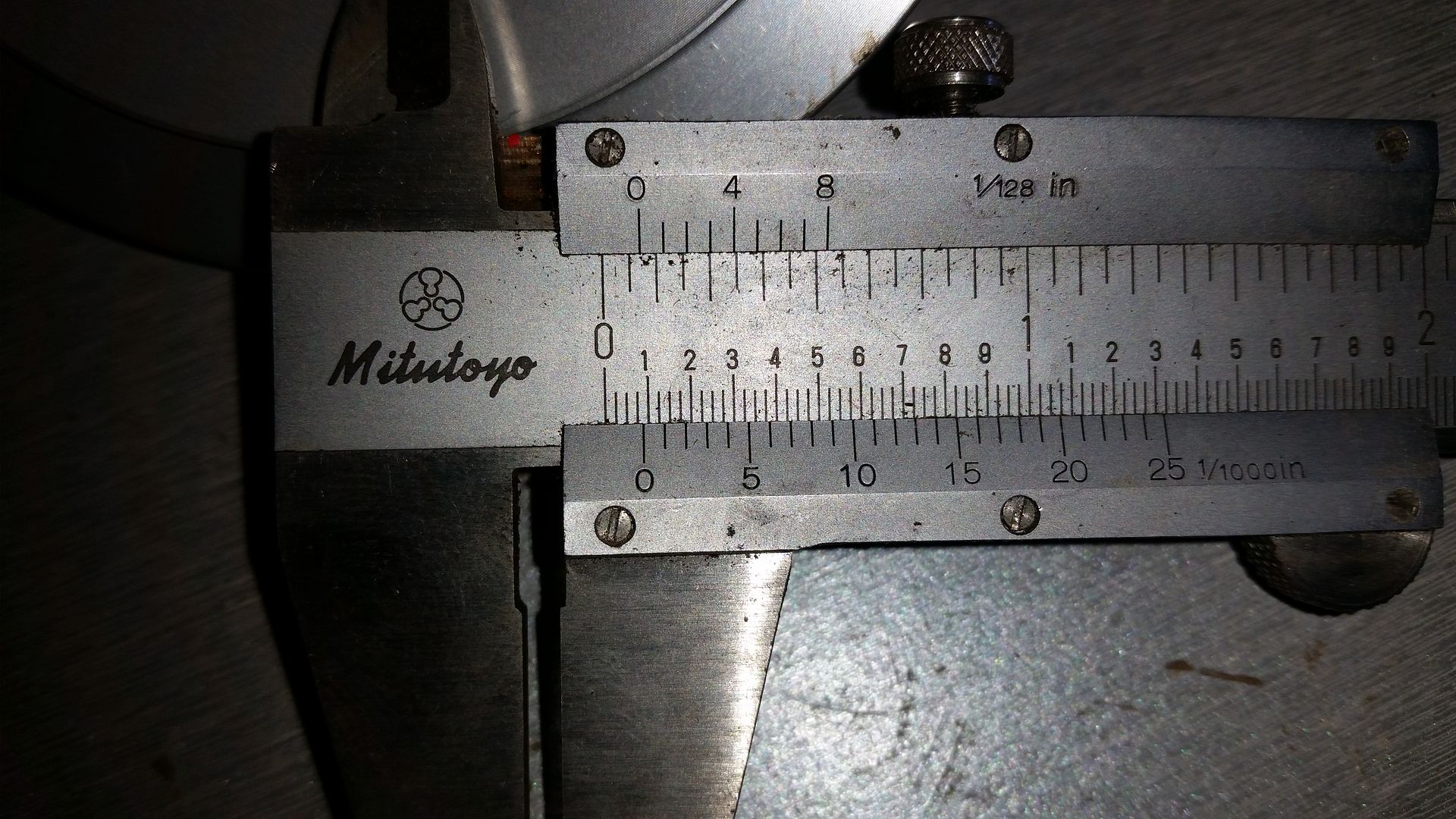

Again, with the "AA" insert, a thin base gasket, and a Wossner piston, squish on my 2014 300 ended up at 1.6mm