d2w

New member

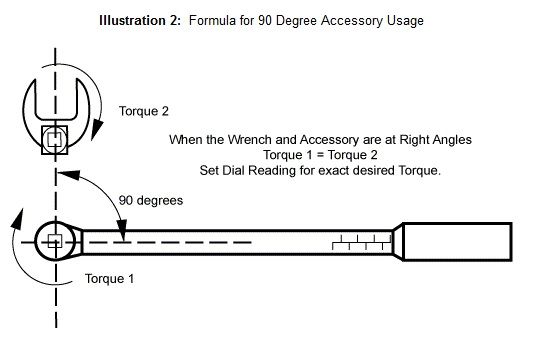

Here's a trick one can use to torque nuts which you can't redily access; applying the torque through an arm 90 degrees to the torque wrench is equivalent. So in the case of the recessed forward cylinder nuts in my ec300 I engage the nuts with the closed end of a 13mm box end wrench, and then I apply the torque (25NM I think) to the open end of the box end wrench. The torque wrench and box end wrench are at 90 degrees to one another. And the connection between the wrenches is conveniently easy as the 13mm wrench can be driven my the 1/2" output of my torque wrench (12.7mm).

The trick to realize is that torque is a function of the length of the arm, but that when the wrench is maintained at 90 degees to the torque wrench the arm length has not changed and so the torque is the same.

Have fun wrenching.

Dale.

The trick to realize is that torque is a function of the length of the arm, but that when the wrench is maintained at 90 degees to the torque wrench the arm length has not changed and so the torque is the same.

Have fun wrenching.

Dale.