I bought and installed a new Vertex piston and rings on my 05 gasser.

The bike has about 4 hours of actual engine run time with the first couple real mellow break ins.

I started by warming it up for about tem min. and then shut it down for the night. I repeated this again the next night. On the next weekend, I went for a nice mellow ride and shut it down after about 20 min, and allowed the engine to cool completely. I did a little faster high RPM riding and allowed it to cool. When I put it away the timer had 1.7 hours on it.

I did go to the local MX track, but I had the flu and went home after only a half hour of riding.

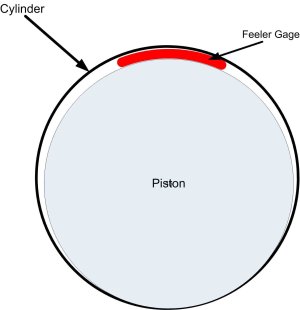

Today at 3.7 hours, she stopped running altogether !! A compression test indicated that I had about 90 lbs. (should have 150 lbs.). I removed the head and found scarring by the exhaust port.

!! A compression test indicated that I had about 90 lbs. (should have 150 lbs.). I removed the head and found scarring by the exhaust port.

While I was doing my top end (a couple weeks ago) I noticed that the piston rings each had a small "N" stamped on the ends. I wondered breifly if they were supposed to be on the top (facing up) or on the bottom (facing down), but I went ahead with the project.

Now I am wondering if I should have paid more attention to that little "N". I called GoFasters and Mark said he would research it with his Vertex vendor and get back to me.

Does anyone here know about this ??

The bike has about 4 hours of actual engine run time with the first couple real mellow break ins.

I started by warming it up for about tem min. and then shut it down for the night. I repeated this again the next night. On the next weekend, I went for a nice mellow ride and shut it down after about 20 min, and allowed the engine to cool completely. I did a little faster high RPM riding and allowed it to cool. When I put it away the timer had 1.7 hours on it.

I did go to the local MX track, but I had the flu and went home after only a half hour of riding.

Today at 3.7 hours, she stopped running altogether

While I was doing my top end (a couple weeks ago) I noticed that the piston rings each had a small "N" stamped on the ends. I wondered breifly if they were supposed to be on the top (facing up) or on the bottom (facing down), but I went ahead with the project.

Now I am wondering if I should have paid more attention to that little "N". I called GoFasters and Mark said he would research it with his Vertex vendor and get back to me.

Does anyone here know about this ??