You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2011 EC 300 Pre Race Season Rebuild

- Thread starter Moto7man

- Start date

Please feel free to add comments or advice.

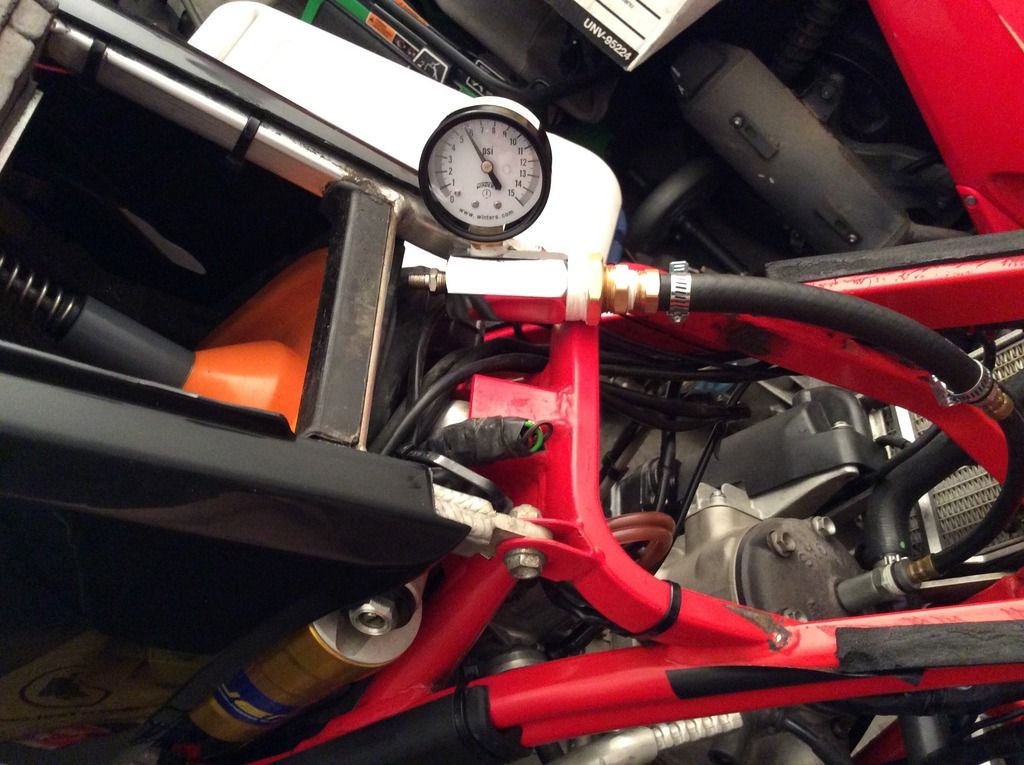

Here is the leak tester that I put together today. It cost about $25.00 total and it worked really weli. This is what I did on my bike. Make sure that you pressure test the tool before you attach it to the engine. Set your engine at BDC, block off your intake, exhaust and powervalve vents. Use a handpump and don't go beyond 5 PSI because after you stop pumping the pressure can still climb about 1 PSI. Any more than 6 PSI can blow out your main seals.

When I attached the gauge to my engine the engine held 6 PSI for 15 minutes with almost no loss( about 1/10 of 1 PSI ). I completed three tests with the same results. So, my engine should be solid after this rebuild.

Here is the 1.5 inch mechanical pipe plug for the exhaust.

Here is the 1.5 inch mechanical pipe plug for the intake,

Did anyone have any comments or opinions of the the 2 Stroke Leak Down Tester?

byost

Gold Level Site Supporter

Zman

Platinum Level Site Supporter

I think your test set up is going to test for (and hopefully not create) leaking gaskets and crank seals. Most leak down detectors used to evaluate ring and valve seal use two guages so you can compare incoming air hose pressure against cylinder pressure at TDC. The percentage difference is supposed to be the leakdown percentage for that cylinder. You typically run the leak down test with open intake and exhaust to allow leakage to occure so you can meaure it.

Last edited:

I think your test set up is going to test for (and hopefully not create) leaking gaskets and crank seals. Most leak down detectors used to evaluate ring and valve seal use two guages so you can compare incoming air hose pressure against cylinder pressure at TDC. The percentage difference is supposed to be the leakdown percentage for that cylinder. You typically run the leak down test with open intake and exhaust to allow leakage to occure so you can meaure it.

I have seen the motion pro leak testers which have dual gauges for the four strokes but the motion pro 2 stroke leak tester only has one gauge.

sorry no

Thanks for the response, anybody else?

I did three heat cycles on the engine and checked the plug color. The plug was was a dark tan color. I was running motul 800 at 40/1.Then I did a 38 mile loop through the the Ocala National Forest. Wow, this thing was fast before but now it rips like a beast. The power spread is the same because I used the same size base gasket but there is a crisper response and more power everywhere.

The compression tester that I made really worked well.

Btw, does anyone know the placement on the spring on trials chain above?

The compression tester that I made really worked well.

Btw, does anyone know the placement on the spring on trials chain above?

RBrider

Gold Level Site Supporter

Sorry, I don't have clue re the clip/spring.

Your leakdown tester looks good to me.

Great job on the whole thread . Thanks for posting it. I know it was time consuming for you.

Here's a Gas Gas noob question for you. What's the best (or correct) way to bleed the cooling system? Or, will it bleed it's self? I'm just finishing up a top end job on a '01 XC 200 and could use some input on that.

Thx again.

RB

Your leakdown tester looks good to me.

Great job on the whole thread . Thanks for posting it. I know it was time consuming for you.

Here's a Gas Gas noob question for you. What's the best (or correct) way to bleed the cooling system? Or, will it bleed it's self? I'm just finishing up a top end job on a '01 XC 200 and could use some input on that.

Thx again.

RB

Sorry, I don't have clue re the clip/spring.

Your leakdown tester looks good to me.

Great job on the whole thread . Thanks for posting it. I know it was time consuming for you.

Here's a Gas Gas noob question for you. What's the best (or correct) way to bleed the cooling system? Or, will it bleed it's self? I'm just finishing up a top end job on a '01 XC 200 and could use some input on that.

Thx again.

RB

Thanks! Sorry for the late response. You could use a Lyle funnel to bleed the system while the bike is at idle but it is not necessary. Fill the system , replace the cap, start it up and let it come to normal temperature, shut it down and let the engine COMPLETELY COOL DOWN, then remove the cap and top off the system. Don't remove the cap while system is hot, you can get severely burned.

fabulous furry

New member

you can switch around the radiator plastic guards so the top becomes the bottom and no dirt will accumulate.

Similar threads

- Replies

- 7

- Views

- 4K

- Replies

- 5

- Views

- 8K