Hi Neil, thanks for the in depth replies, much appreciated.

Some answers to these questions,

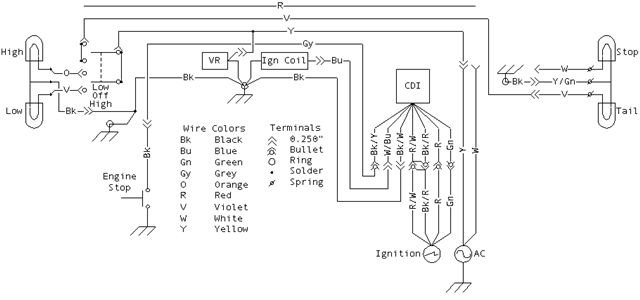

I have that wiring diagram, followed all the colours / connectors and it seems ok, no wrong connections. Got my mate to look over it too, he couldnt see a problem.

I tried a 100w bulb, popped it straight away.

Yes it is the yellow wire connected not the white.

I agree the regulator must be working just not properly. When the regulator blew it put out 30+ volts at the headlight and totally shattered the headlight bulb as if i had hit the glass with a hammer.

I have tried a known good gas gas regulator on my bike it acts in a similar way to the trail tech, 12v at idle, upto 16v when revved.

The regulator I have is the one at the bottom of this link.

http://www.trailtechproducts.co.uk/acatalog/Regulator_Rectifier.html

Trail Tech AC Voltage Regulator

- Improved AC Regulator with Adjustable Output.

- Universal voltage regulator limits voltage to 12.0-16.0 volts for AC systems (DC systems require a regulator/rectifier.)

- Conditions circuit to eliminate electrical spikes, protect from lamp blow-outs, and reduce flicker and dimming.

- Dial-a-Brightness for halogen and quartz lights:

- At 14+ VAC setting, the lamps will approach HID lumens (~70%) but lamp life is short (good for racing.) ~25 hour lamp life.

- At standard setting, about 13.8 VAC, the lamps should last about 500 hours.

- At minimum setting, the lamps are not as bright as HID (~30%), but last over 1,000 hours.

Included in Trail Tech plug-and-play high-output AC electrical systems with model-specific connectors; no cutting or splicing required.

Designed and manufactured by Trail Tech.