Wow, thanks for sharing that uawelder, just spent 30 minutes reading it and getting my head around it. Very interesting.

Whoever hallsy is, he's definitely put some work into that post.

So assuming that info is all correct...

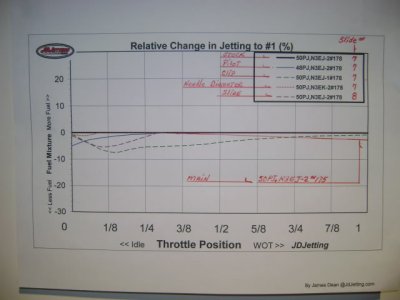

I can see that by fitting a larger diameter/leaner needle with the same clip position, and all other components remaining the same...the only effect it has is to lean off the first 1/16 of throttle opening! Displayed by the red dotted line.

I totally agree with uawelder and Jakobi. Graphs dont show it all. I had a similar understanding problem, but James (Dean) could clarify it. Its great that he's close to the base and you can talk to him though he is very busy.

First is, you dont know what a 1/16 or a 1/8 throttle opening definitely is. So we talk about what we feel, but thats estimated.

Therefore it is indeed a very good idea to mark the throttle grip to see what the values really are. You will immediately notice how little 1/16 and 1/8 is.

Though that sounds very simple it helps to better understand what throttle openings you feel vs how much the throttle is opened in reality.

To be honest, I was expecting a larger/leaner needle to lean off the mixture over most of the throttle positions, obviously I was mistaken.

That is because what you see is not what you get

Especially when comparing graphs. The straight diameter is very short and even it it seems the needle is straight further down its length it isnt. But as most people you can feel that - as one of the guys already said - the straight diameter effects the jetting further than 1/16, probably up to 1/8 throttle opening.

Just as a side note concerninj JD:

One of the major improvements of JD's needles is, that you can quickly get rid of a possible low down burble, caused by a too rich mixture due to a too short straight portion of the needle.

Slower riders, doing lots of tricky tech stuff have more problems with this effect than fast riders or racers never being at 1/8 throttle opening longer than half a second.

Second thing is, that JD leans the mixture over 70% of the rev range by simply using thicker needles. [As far as it concerns JD kit for GG 2018 EC/GP, it may be different on other bikes/carbs]

This lets the engine react crisp and makes it feel more responsive. And it is the reason why he recommends a bigger main jet than standard. JD178 vs 170/172 standard, depending on the country the bike is delivered to.