bergerhag

Silver Level Site Supporter

A fellow swedish rider had his '09 front axle snap.

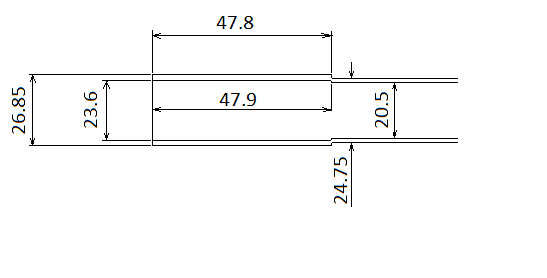

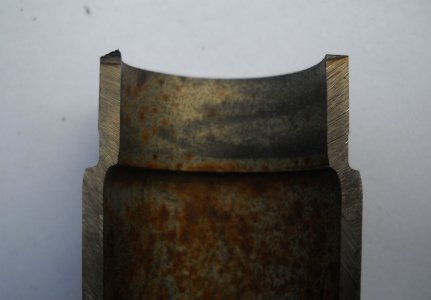

I went out to shed and measured up my '10 axle. My bike is not rolling one more meter with that axle.

The bigger inner diameter where the fork yoke mounts passes by a tiny amount the larger outer diameter of same area. This makes the material thickness at the edge of spacer less than 0.6 mm [edit measured 1.3 mm] (0.0236 inches).

Fortunately my '05 450 has got anoter style of axle. Swap imminent.

I went out to shed and measured up my '10 axle. My bike is not rolling one more meter with that axle.

The bigger inner diameter where the fork yoke mounts passes by a tiny amount the larger outer diameter of same area. This makes the material thickness at the edge of spacer less than 0.6 mm [edit measured 1.3 mm] (0.0236 inches).

Fortunately my '05 450 has got anoter style of axle. Swap imminent.

Attachments

Last edited: