I read the tech article on head squish. I am seriously about to go home and take that measurement.

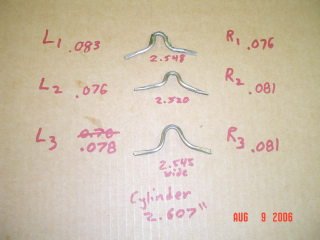

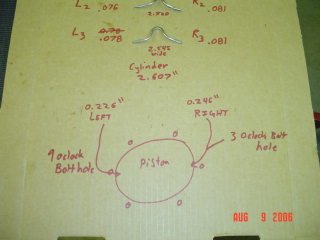

I noticed that the solder strand was placed on the piston going from left to right with a little hump extending forward in the middle.

It was suggested that this measurement should be done a couple times.

Shouldnt I take a measurement on the forward and back of the piston as well ? Why or why not ??

With regard to taking more than one measurement, I am concerned about the repeated assembly and disassembly of my head from the cylinder. Would I really need to fully torque the head bolts just for this measurement ? In this way, I think I might save some compression on my head gasket (o-rings). I could also simply order a new set of head gasket o-rings, but dont know if its necessary. Your thoughts ??

I noticed that the solder strand was placed on the piston going from left to right with a little hump extending forward in the middle.

It was suggested that this measurement should be done a couple times.

Shouldnt I take a measurement on the forward and back of the piston as well ? Why or why not ??

With regard to taking more than one measurement, I am concerned about the repeated assembly and disassembly of my head from the cylinder. Would I really need to fully torque the head bolts just for this measurement ? In this way, I think I might save some compression on my head gasket (o-rings). I could also simply order a new set of head gasket o-rings, but dont know if its necessary. Your thoughts ??

Last edited by a moderator: