bergerhag

Silver Level Site Supporter

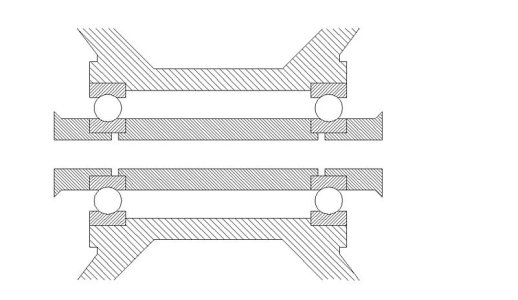

The rear wheel bearing/spacer setup is like no other thing I ever seen. The inner spacer has less inside diameter than the bearings, and a small portion is sort of inserted into the bearing. This makes it impossible to pry the spacer to one side to give access for a drift to punch out the bearings. Be prepared that you might need a new inner spacer. Bearings are std 6004 2RS.

It was a couple of months since i did this, and I might not remember all details. But it's close.

1. Remove the outer spacers. They fit snugly in the

bearing inner racers and might be stuck.

2. Find some socket that fits inside the bearing, but sits against the inner spacer, to use as a drift. The inner spacer inner diameter is smaller than

bearing inner diameter, and it hooks inside the bearing. See attached drawing.

3. You need to drive out the opposite bearing using the inner spacer as a drift extension. It is likely it will be thrashed, as it is in aluminium. You only need to drive out the bearing a few millimeters, just so that the spacer is freed from the bearings. Then you can use normal wheel bearing change procedures, and drive it out with a long drift, working opposite sides of the

bearing. If you got access to a hydraulic press it might be easier on the inner spacer.

4. Once you got the first bearing out, it's easy to drive out the other side.

5. [optional] Pop out the new bearing seals with a small pick working from the inner edge and the pack the bearings full with waterproof grease. The wheel bearings rotate with low rpm's so it's ok.

6. If you are reusing your old inner spacer, make sure the ends are not damaged, and that they slide into the bearings.

7. When mounting the new bearings, make sure you align the inner spacer so that it will fit into the bearing inner races.

It was a couple of months since i did this, and I might not remember all details. But it's close.

1. Remove the outer spacers. They fit snugly in the

bearing inner racers and might be stuck.

2. Find some socket that fits inside the bearing, but sits against the inner spacer, to use as a drift. The inner spacer inner diameter is smaller than

bearing inner diameter, and it hooks inside the bearing. See attached drawing.

3. You need to drive out the opposite bearing using the inner spacer as a drift extension. It is likely it will be thrashed, as it is in aluminium. You only need to drive out the bearing a few millimeters, just so that the spacer is freed from the bearings. Then you can use normal wheel bearing change procedures, and drive it out with a long drift, working opposite sides of the

bearing. If you got access to a hydraulic press it might be easier on the inner spacer.

4. Once you got the first bearing out, it's easy to drive out the other side.

5. [optional] Pop out the new bearing seals with a small pick working from the inner edge and the pack the bearings full with waterproof grease. The wheel bearings rotate with low rpm's so it's ok.

6. If you are reusing your old inner spacer, make sure the ends are not damaged, and that they slide into the bearings.

7. When mounting the new bearings, make sure you align the inner spacer so that it will fit into the bearing inner races.