Bobt250

Platinum Level Site Supporter

Long winded but I hope worth it,

The back story. My starter never worked very well, especially when cold. It would routinely fail to engage or cut out quickly after barely turning the engine over. It also made lots of clashing gear noises too. The conventional wisdom was that the gears needed more space which seemed to be confirmed by the fact that Gas Gas provided a "fix" in the form of a gasket set that included a thicker gasket albeit it also included a thinner one too. I installed the thicker gasket which seemed to help at first but didn't really. After 2 years of barely working and making lots of clashing noises while attempting to use it the gears gave up. I lost a couple of ring gear teeth and the pinion gear teeth were all rounded off. I did notice that the pinion teeth were rounded off only on the tips which showed that I had the gears pretty far apart so further opening the gap didn't seem to be an option.

I bought a new ring and pinion (bendix) at a cost of $100 for the ring gear and a whopping $200 for the bendix. I installed the new parts with the standard thickness gasket since I didn't like how the shallow tooth engagement ripped the top of the teeth off. The ring gear came with two thin shims which would have tightened the gap between gears so given the conventional wisdom and the fact that there weren't any shims in there stock I left them out.

I had hoped Gas Gas did something to the bendix and that my shiny new one would work better. Nope, it worked worse than ever. After spending so much money only to have it work worse I was pretty pissed. After three rides the teeth stripped off again. That was much worse life than before and I didn't know why. I pretty much gave up hope and decided to kick start it only to have my kickstarter break. Not a happy camper.

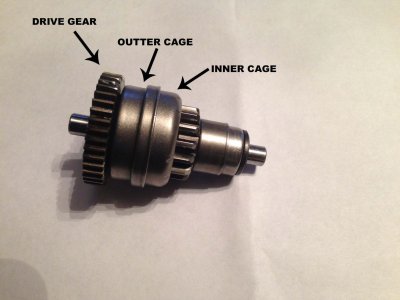

I decided I wanted a starter so I set about finding a more fairly priced source for the bendix. I reasoned that the bendix probably was an off the shelf item that fit something else. After much searching I didn't find an exact replecement but I did find a replacement that had all the necessesary parts needed to fix mine. What I found was a bendix from a Honda Elite CH80 scooter is the exact same thing with the exception of the larger gear driven by the starter motor. That gear has more teeth than the Gas Gas bendix but that's the part that never goes bad because it's always fully engaged. I found that you can take apart your bendix and replace all the parts that make a difference and the Honda bendix can be had for $39 all day long on Ebay with free shipping. There are also used ones for cheap which is what I bought since I was experimenting. I bought a used one for $14. The part number is SMU5011.

I also bought a bendix which fits a chinese 50cc scooter, also for experimenting. The reason I bought the 50cc scooter bendix is that it also has 14 teeth on the pinion but more importantly it costs under $15 brand spanking new. If I could make that one work it would be a huge victory. It was not to be as the flyweight assembly is smaller but hey, I'm happy with $39 as opposed to $200 from Gas Gas.

I put the new pinion/flyweight assembly from the Honda CH80 scooter on the Gas Gas gear/shaft. While I was at it I slightly stretched the spring that holds the flyweights in place as was suggested by someone else on this forum. I also used the return spring from the 50cc Chinese scooter because it was a little "lighter" tension spring. If I was going for it I was going all the way. Looking good so far. Next comes assembly on the engine. I took careful measurements by measuring from the teeth of the gears to the gasket surfaces of the cases and it was obvious to me that the spacing was indeed very loose and that even a thinner gasket wouldn't get the gears close enough to prevent the tips from rounding off again. I installed the 2 shims that came with the new ring gear. I still felt like there was going to be excessive spacing between the gears given what my measurements were telling me so I found that I had some washers in my stash that happened to be the exact same inner diameter and were a lot thicker. They are about 1/16" thick and with one of them installed I was where I wanted to be. I was looking for about 1/2mm between the tip of the pinion tooth and the root of the ring gear teeth not counting gasket thickness. I applied a dab of STP to the teeth of the ring gear and put it all together with the thinnest gasket from the Gas Gas kit.

I have to tell you that I was pretty nervous about pushing the starter button. I had high hopes before and was always disappointed. When I pushed the button on a cold engine I was shocked when it engaged immediately, cranked over and over and perhaps best of all it sounded smooth and relatively quiet. Gone were all the clashing noises I had grown accustomed to. I tried it several times and it worked each and every time. It stays engaged for as long as your finger is on the button...every time. I was pumped. I went riding the next day and from the time I rolled it off the the truck in 25 degree weather until I ran the bike after washing it post ride it worked 100% of the time on the first push of the button and without any bad noises. It never worked like this from the time it was new. I can say that I'm in love with my Gas Gas all over again.

In conclusion. #1 Gear spacing is important but opening up the spacing isn't what makes it work well and will only get you stripped/broken teeth. I have a strong opinion that tighter is better particularly for extending the life of the teeth. #2 Should you need a bendix you don't need to spend $200. I spent $14 on the one I ended up using. What really fixed the engagement? Probably stretching the spring as was suggested to me by someone on this forum. Most importantly, what I thought was a bad design actually can be made to work. If you hate your starter you might want to try fixing it. Should you have to? no, but if you want it to work you must fix it. Mine works great.

The broken ring gear on the left. The spacers supplied by Gas Gas, the spacer I used is on the right.

The back story. My starter never worked very well, especially when cold. It would routinely fail to engage or cut out quickly after barely turning the engine over. It also made lots of clashing gear noises too. The conventional wisdom was that the gears needed more space which seemed to be confirmed by the fact that Gas Gas provided a "fix" in the form of a gasket set that included a thicker gasket albeit it also included a thinner one too. I installed the thicker gasket which seemed to help at first but didn't really. After 2 years of barely working and making lots of clashing noises while attempting to use it the gears gave up. I lost a couple of ring gear teeth and the pinion gear teeth were all rounded off. I did notice that the pinion teeth were rounded off only on the tips which showed that I had the gears pretty far apart so further opening the gap didn't seem to be an option.

I bought a new ring and pinion (bendix) at a cost of $100 for the ring gear and a whopping $200 for the bendix. I installed the new parts with the standard thickness gasket since I didn't like how the shallow tooth engagement ripped the top of the teeth off. The ring gear came with two thin shims which would have tightened the gap between gears so given the conventional wisdom and the fact that there weren't any shims in there stock I left them out.

I had hoped Gas Gas did something to the bendix and that my shiny new one would work better. Nope, it worked worse than ever. After spending so much money only to have it work worse I was pretty pissed. After three rides the teeth stripped off again. That was much worse life than before and I didn't know why. I pretty much gave up hope and decided to kick start it only to have my kickstarter break. Not a happy camper.

I decided I wanted a starter so I set about finding a more fairly priced source for the bendix. I reasoned that the bendix probably was an off the shelf item that fit something else. After much searching I didn't find an exact replecement but I did find a replacement that had all the necessesary parts needed to fix mine. What I found was a bendix from a Honda Elite CH80 scooter is the exact same thing with the exception of the larger gear driven by the starter motor. That gear has more teeth than the Gas Gas bendix but that's the part that never goes bad because it's always fully engaged. I found that you can take apart your bendix and replace all the parts that make a difference and the Honda bendix can be had for $39 all day long on Ebay with free shipping. There are also used ones for cheap which is what I bought since I was experimenting. I bought a used one for $14. The part number is SMU5011.

I also bought a bendix which fits a chinese 50cc scooter, also for experimenting. The reason I bought the 50cc scooter bendix is that it also has 14 teeth on the pinion but more importantly it costs under $15 brand spanking new. If I could make that one work it would be a huge victory. It was not to be as the flyweight assembly is smaller but hey, I'm happy with $39 as opposed to $200 from Gas Gas.

I put the new pinion/flyweight assembly from the Honda CH80 scooter on the Gas Gas gear/shaft. While I was at it I slightly stretched the spring that holds the flyweights in place as was suggested by someone else on this forum. I also used the return spring from the 50cc Chinese scooter because it was a little "lighter" tension spring. If I was going for it I was going all the way. Looking good so far. Next comes assembly on the engine. I took careful measurements by measuring from the teeth of the gears to the gasket surfaces of the cases and it was obvious to me that the spacing was indeed very loose and that even a thinner gasket wouldn't get the gears close enough to prevent the tips from rounding off again. I installed the 2 shims that came with the new ring gear. I still felt like there was going to be excessive spacing between the gears given what my measurements were telling me so I found that I had some washers in my stash that happened to be the exact same inner diameter and were a lot thicker. They are about 1/16" thick and with one of them installed I was where I wanted to be. I was looking for about 1/2mm between the tip of the pinion tooth and the root of the ring gear teeth not counting gasket thickness. I applied a dab of STP to the teeth of the ring gear and put it all together with the thinnest gasket from the Gas Gas kit.

I have to tell you that I was pretty nervous about pushing the starter button. I had high hopes before and was always disappointed. When I pushed the button on a cold engine I was shocked when it engaged immediately, cranked over and over and perhaps best of all it sounded smooth and relatively quiet. Gone were all the clashing noises I had grown accustomed to. I tried it several times and it worked each and every time. It stays engaged for as long as your finger is on the button...every time. I was pumped. I went riding the next day and from the time I rolled it off the the truck in 25 degree weather until I ran the bike after washing it post ride it worked 100% of the time on the first push of the button and without any bad noises. It never worked like this from the time it was new. I can say that I'm in love with my Gas Gas all over again.

In conclusion. #1 Gear spacing is important but opening up the spacing isn't what makes it work well and will only get you stripped/broken teeth. I have a strong opinion that tighter is better particularly for extending the life of the teeth. #2 Should you need a bendix you don't need to spend $200. I spent $14 on the one I ended up using. What really fixed the engagement? Probably stretching the spring as was suggested to me by someone on this forum. Most importantly, what I thought was a bad design actually can be made to work. If you hate your starter you might want to try fixing it. Should you have to? no, but if you want it to work you must fix it. Mine works great.

The broken ring gear on the left. The spacers supplied by Gas Gas, the spacer I used is on the right.

Attachments

Last edited: