(F5)

Gold Level Site Supporter

yeah my local kart guy uses one & I read one of the top ex Aprilia GP guys saying he uses one so it was a clear indication that it was a good idea. So far on my race engine I found I was getting huooge leakage on a cylinder that was producing good but not spectacular power & polishing the bores.

this sort of thing. heaps of howtos on Youtube.

http://www.harborfreight.com/cylinder-leak-down-tester-94190.html

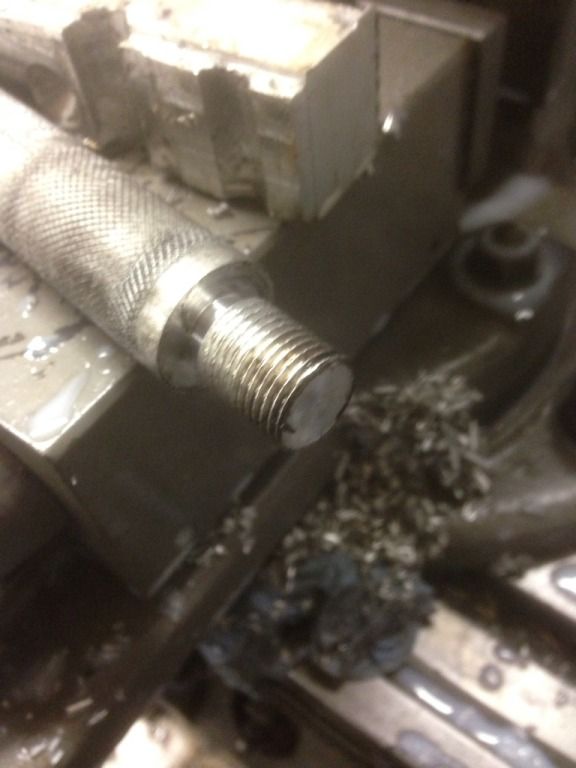

I built a 2 stroke leak tester many years ago which checks for crankcase leaks, but this type above is purely ring seal.

this sort of thing. heaps of howtos on Youtube.

http://www.harborfreight.com/cylinder-leak-down-tester-94190.html

I built a 2 stroke leak tester many years ago which checks for crankcase leaks, but this type above is purely ring seal.