You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R&B designs, NO MORE gas gas mods?

- Thread starter Adam500

- Start date

motopsycho87

New member

I'm the Toolroom manager at a brass foundry that supplies aerospace grade copper alloys. I normally just do this stuff for myself or mates after hours, but I'm open for work for the GG community. Imho the carb dividers and things are shit, you gain velocity in one place and lose it in another. Singh grooves, now I've ridden an unmodified 300 straight after mine, definitely improve the low end. Powervalve reshaping also makes a difference at the top end as there is a mega harsh step on the older models, most people have the tools to do that at home. I'm not going to touch anyone's ports as there's a degree of liability I'm not comfortable with, and crank rebuilding, there's enough pros around at reasonable price you'd be better off going elsewhere!

So yeah! Head mods

So yeah! Head mods

Machined this today for a member of the site.

That looks Purtty to me.

Here is a Pic on my head I machined up before polishing.

Attachments

Sounds like we have motopsycho87 in the UK, Eric Gorr in Wisconsin and ZRT1200 are you open for business in Michigan?

Well right now my plate is full but it will open up more towards the end of summer then I can start cutting heads. I have two rental houses that I am fixing up currently to sell and that is sucking up all my spare time at the moment. I am Done with Renters!!! If you want to have a rental get a 6 to 8 unit apartment building or dont bother renting. JMO.

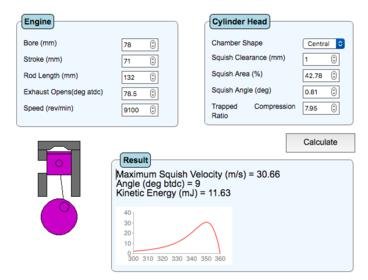

When I get a chance I will post up CC volumes for what octane gas for the 200, 250, & 300. I have personally tried 15, 19, 20, 21, 22, 24, 30, & 34 MSV on various engines through the years. (MSV = Maximum Squish Velocity). The higher the MSV the faster the engine rev's. It also makes it more prone to detonate. A low MSV is great for 1/4 mile WOT runs but not worth beans for pulling the front end up over a log. From my experience I would recommend 20-22MSV as that is a very good mix of quick throttle response and top end running.

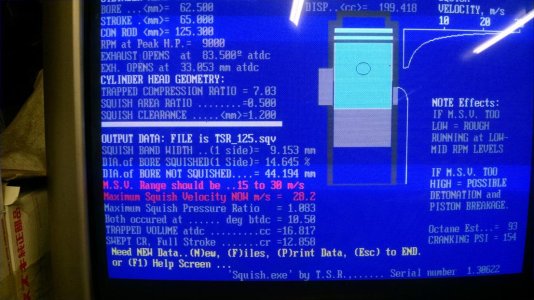

Here is a couple of Pics of my TSR software. This is was what I cut my 200 head to the first time with slight detonate. I re-cut it sense then to get rid of the detonation as the MSV was to high but I wanted to try it. But this will give you guys a idea of what the TSR software will do.

Attachments

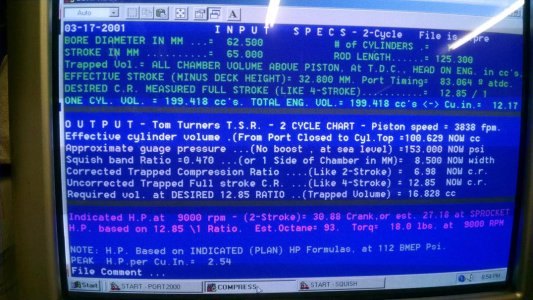

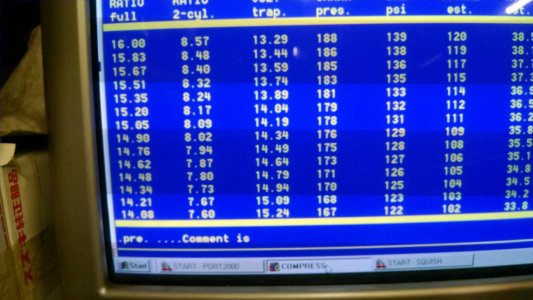

And here is a few pics of the Torqsoft software. These pics are from a Drag Race Snowmobile Engine I did this winter. As you can see the two programs very and thats a good thing as it gives me more info to do a better job. One of the important things to cutting heads is to know what the installed CC volume is with the piston at TDC & the squish gap. The exhaust port height is important as well but you need to measure from the deck height to top of the exhaust port. Not the top of the cylinder to the top of the exhaust port.

Attachments

(F5)

Gold Level Site Supporter

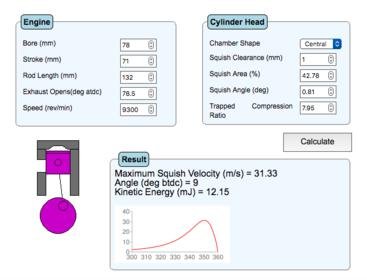

I used TSR sw too, but getting harder to find a platform it will run on properly. Engmod has well taken over but I can't justify it.

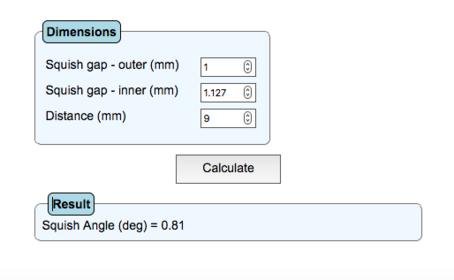

On my 07 300 the chamber was like 13degrees and the Woosner piston 9degrees. So I played it safe and cut 10degrees so it is mostly parallel but def not converging to the centre.

Then I cut the sealing surface so there was a 3.3 step to the chamber. On my bike this meant a 1.1mm squish I believe every bike may be different.

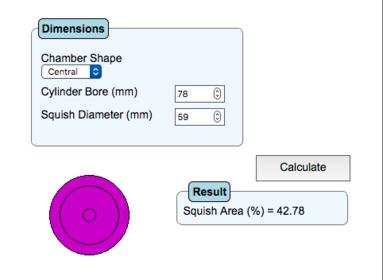

It was 12mm squish width which equates to 56% squish. Cutting it back to 10mm (48%) and making the chamber quite steep at the edges allowed for a 13:1 ratio and reasonable msv (which I didn't seem to write down and can't be bothered firing up an old PC to find out).

This gets you totally in the zone but you must measure and reduce compression if you gas is a bit lousy.

On my 07 300 the chamber was like 13degrees and the Woosner piston 9degrees. So I played it safe and cut 10degrees so it is mostly parallel but def not converging to the centre.

Then I cut the sealing surface so there was a 3.3 step to the chamber. On my bike this meant a 1.1mm squish I believe every bike may be different.

It was 12mm squish width which equates to 56% squish. Cutting it back to 10mm (48%) and making the chamber quite steep at the edges allowed for a 13:1 ratio and reasonable msv (which I didn't seem to write down and can't be bothered firing up an old PC to find out).

This gets you totally in the zone but you must measure and reduce compression if you gas is a bit lousy.

I used TSR sw too, but getting harder to find a platform it will run on properly. Engmod has well taken over but I can't justify it.

On my 07 300 the chamber was like 13degrees and the Woosner piston 9degrees. So I played it safe and cut 10degrees so it is mostly parallel but def not converging to the centre.

Then I cut the sealing surface so there was a 3.3 step to the chamber. On my bike this meant a 1.1mm squish I believe every bike may be different.

It was 12mm squish width which equates to 56% squish. Cutting it back to 10mm (48%) and making the chamber quite steep at the edges allowed for a 13:1 ratio and reasonable msv (which I didn't seem to write down and can't be bothered firing up an old PC to find out).

This gets you totally in the zone but you must measure and reduce compression if you gas is a bit lousy.

I have my TSR on a old PC in the garage. I sure wish tom would have made it a windows based software instead of that dang DOS. If you ever have a problem with the TSR saying it has a Virus reset the PC's clock to the year 2000. Who ever made the software put in a internal clock and it wont work after X amount of time.

Torqsoft head program is around $25 a year so its pretty cheap VS what we paid for TSR. The one thing I like about the Toqsoft is it shows how much MSV you loose when you cut a angle on it where the TSR does not. It also has some free programs as well.

http://www.torqsoft.net/

My Fix for lousy gas is to install the next colder heat range spark plug. If you have a B8 in it and get spark knock switch to a B9 an it will cure it. You will not see any power loss by the seat of the pants feeling anyways. I have never dyno'ed to see if there is a power loss by going 1 step colder spark plug though. I have advanced the timing and put in a colder plug to stop the knock and it helped the bottom end a fair amount.

I always carry two plugs with me. One B8 and one B9. You never know when you are going to get crap fuel and its easy to switch it out VS destroying your engine.

swazi_matt

Active member

Machined this today for a member of the site.

Why is it the prettiest parts are always on the inside?

I'd like to draw your attention to boobs. I mean I'm just saying.

LOL....that is true.

swazi_matt

Active member

I'd like to draw your attention to boobs. I mean I'm just saying.

Touche lol

twowheels

Active member

Note to self. Must,Stay,Off, the internet,AfterDrinking.

Now that's just funny

motopsycho87

New member

That looks Purtty to me.Do you have software to figure out MSV??? I use both Torqsoft & TSR.

Here is a Pic on my head I machined up before polishing.

Nah, i just read the books and tried a couple different combinations from there. Found what works, happy days! Imagine calculating MSV with Singh grooves...

That and 7 years down the line in my engineering education, the more i learn trial and error works far better than math, where do you think the "standard numbers" came from anyway... Trial and error

Attachments

Nah, i just read the books and tried a couple different combinations from there. Found what works, happy days! Imagine calculating MSV with Singh grooves...

It can be done but boy what a Pain in the Arse that would be.

Just to keep everyone updated.

After having quite a talk with Ron, he agreed to do the work for me.

I don't think he will do anymore gas gas mods. He made an exception for me because we kinda had a deal worked out before he decided on his vacation that he didn't want to do gas gas work anymore.

Its a shame he doesn't do them anymore because HOLY COW!

What a difference the head and carb mod make! Really wakes up the motor.

Super crisp bottom end response. The bike rips!

Ron does TOP quality work.

After having quite a talk with Ron, he agreed to do the work for me.

I don't think he will do anymore gas gas mods. He made an exception for me because we kinda had a deal worked out before he decided on his vacation that he didn't want to do gas gas work anymore.

Its a shame he doesn't do them anymore because HOLY COW!

What a difference the head and carb mod make! Really wakes up the motor.

Super crisp bottom end response. The bike rips!

Ron does TOP quality work.

Similar threads

- Replies

- 4

- Views

- 3K

- Replies

- 6

- Views

- 4K

- Replies

- 6

- Views

- 5K