StuJohnson

New member

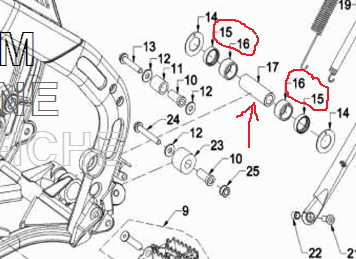

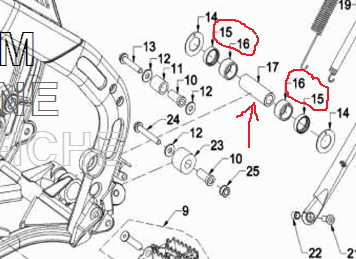

So after installing the new linkage skid plate I started to think how it was rather interesting how the "axle" (per OEM part description) came right out of the front linkage. So decided to remove again and inspect.

Sure enough one of the needle bearings has gone bad.....

Glad I found it, and not glad I have to change it.

And figure if I do one I might as well do both.

Has anyone had to do this??? Dumb question.....

Can you provide me any advice or input on how to remove and install?

Is there a part crossover or GG OEM only?

Sure enough one of the needle bearings has gone bad.....

Glad I found it, and not glad I have to change it.

And figure if I do one I might as well do both.

Has anyone had to do this??? Dumb question.....

Can you provide me any advice or input on how to remove and install?

Is there a part crossover or GG OEM only?