First of all, I?d like to introduce myself to the Forum users:

My name is Leandro, I live in Brazil, and I have a GasGas EC 250 2008. I have this motorcycle since 2010 and during this period I?ve had to manage 2 different problems that have been solved in two different moments.

My bike has never shown a consistant idle, which means the engine use to die after about 10 seconds on idle mode, and also used to die on longer descents or in other technical tracks, where I always had to keep the throttle slightly open to avoid the motor to die. I never thought about the possibility of adjusting the idling rotation into a slightly higher rotation to minimize this problem, because I thought it wouldn?t be nice on riding a bike with a high idle, and that this adjustment would not solve my problems ...

The second problem I was facing was carburetion. The low quality needle that originally came on my bike (N1EF), was excessively ?rich? in its straight part, forcing me to use it in a very low position, because in the contrary, the working up to 1/4 throttle was very rich, causing crashes and rough ?low quality? responses when throttling. The problem of calibrating to low the needle was that from 1/4 to 3/4 throttling, the carburetor has became very impoverished, and the transition from low to medium speed was very abrupt, producing a ?remarkable kick? considering the carburetion changed from rich to lean in such a quick time of throttle.

Seeking a solution for this problem, I searched a lot in this and other related forums, where Ive found several posts about the needles Triple Taper, especially the NE series. I ordered several needles, among them the NECJ, NECW, NEDW and NECH from the U.S.A and after several tests, considering the temperature and humidity variances, because in my area the temperature ranges from 5?C in winter to 40? C in the summer, the needles that best result produced to my riding style are the NECW and NEDW.

With needle exchange the carburetion problem was solved, I loved the performance of the engine with these new needles. But the problem of idle remained the same, in other words without idle .... So, as I had worked in many other things that could influencing the instability of idling, such as the reed valves, the crankshaft seals, the fake air intake, the level of the float into the carburetor. I changed even the swap OEM throttle cable for a MotionProT3 - that by being much longer allows a better free play, I decided to talk to my good friend and excellent mechanical and engine adjuster called Dilvo Favretto about the change in the Squish band, who confirmed that this should be an excellent change to be done, because it would be optimize the engine performance.

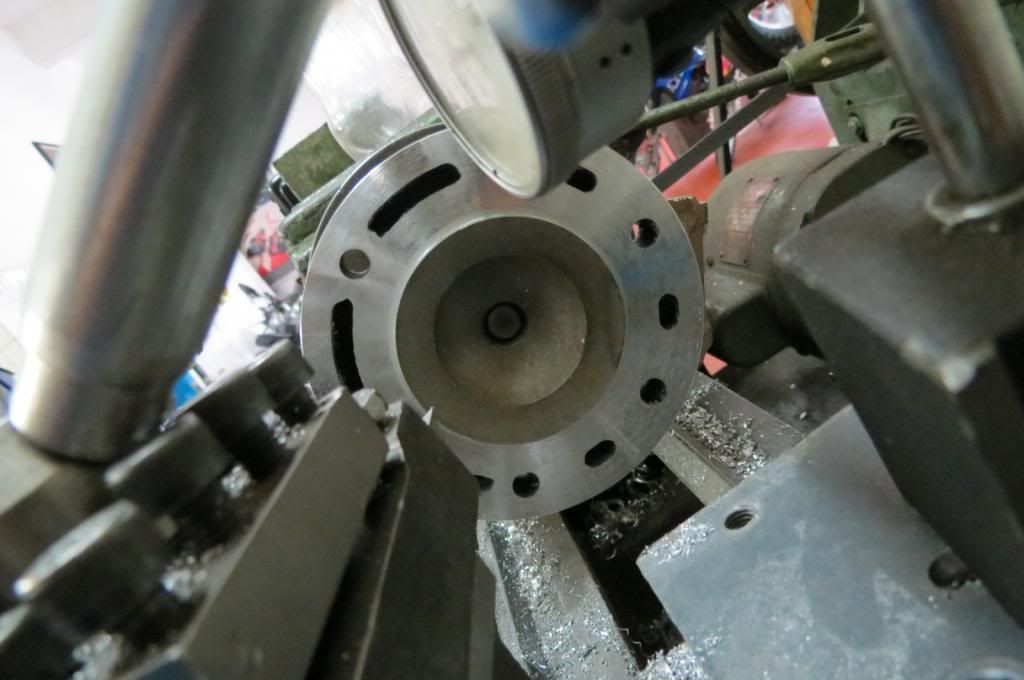

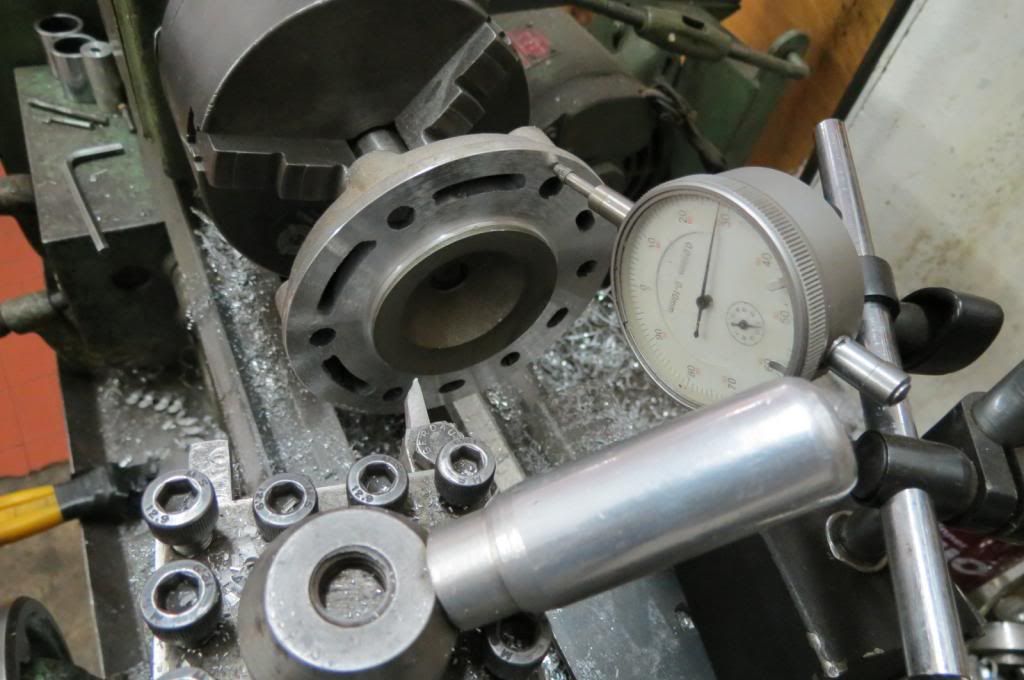

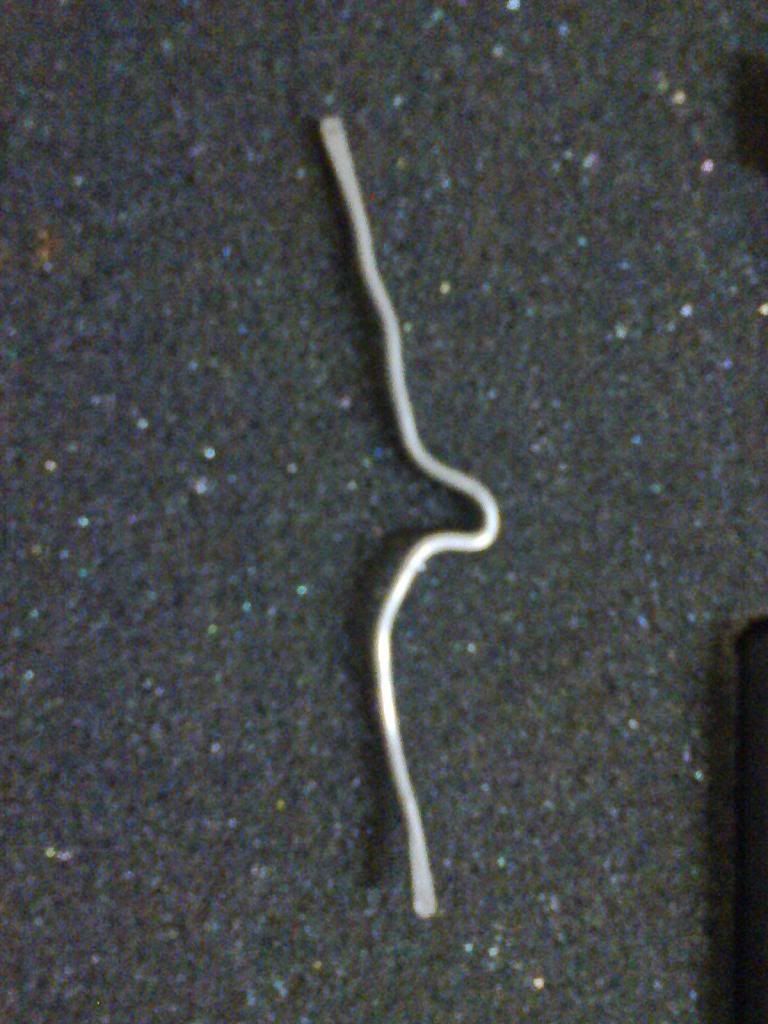

Agreed on the services, I took the bike to his workshop, and it was verified the original Squish band and the result was really scary ...2.4 mm! Once changes were done, the new measure of the squish band was 1.00 mm.

As we were with the engine partially opened, we took this opportunity to change the height of the cylinder, using 2 base gaskets, being one of 0.4 mm and other of 0.8 mm. With these measures, the windows stayed 0.5 mm below the top of the piston.

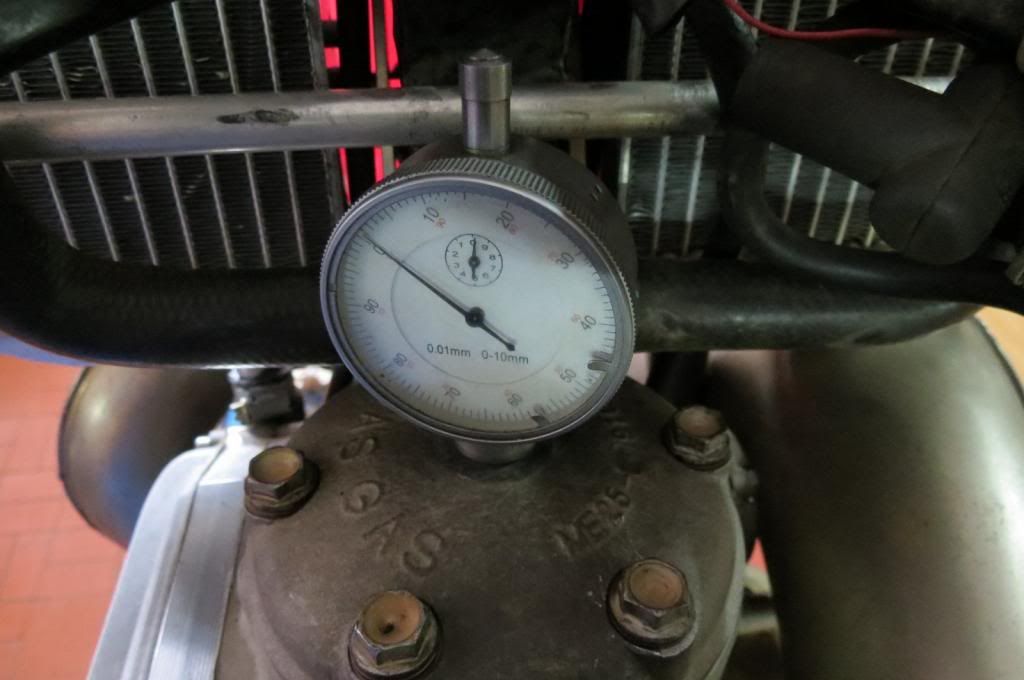

Another important check we did, was the check of the ignition timing. My bike was in 1.3mm BTDC. We have advanced to 1.6mm BTDC and the result was excellent, idling more stable and with better answers to the throttle.

After all this changes, we had just to test the bike on the fields?

The result could not be better, with the new adjustment of Squish band, the responses from the engine were much faster, the engine started to work in a ?clean way? even the noise was different, more aggressive, looking like the noise of a Motocross 2T. Now, any small adjustment of the air screw is being noticeable, much different than before.

I?m going to add some pics about the job we did.

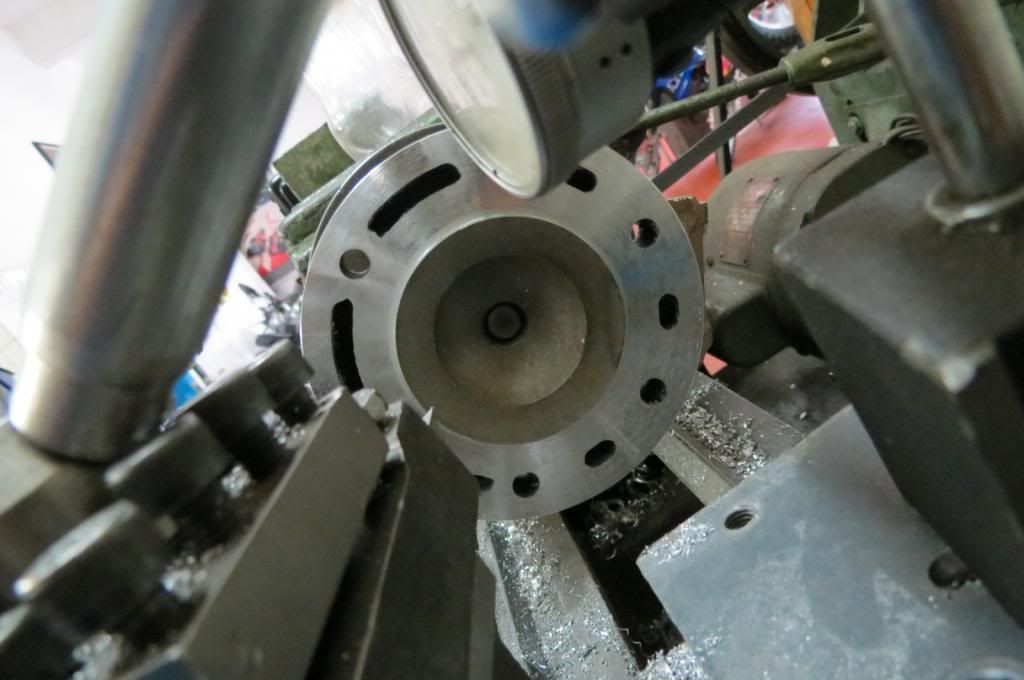

Disassembling of the Head

Notice in the pictures below the excellent condition of the piston when disassembling. The piston had 64 hours of use, and the wear of this period was 0.002 mm. Since ever, the oil used is Motul 800 in the ratio of 1.5%.

Head before setting the squish band:

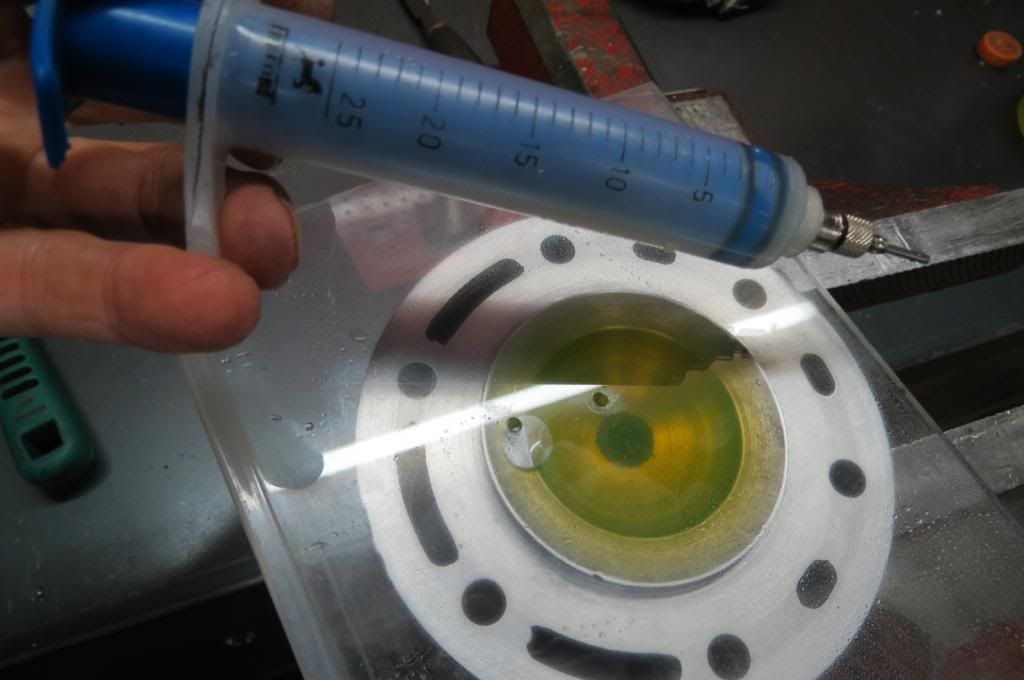

After work was done:

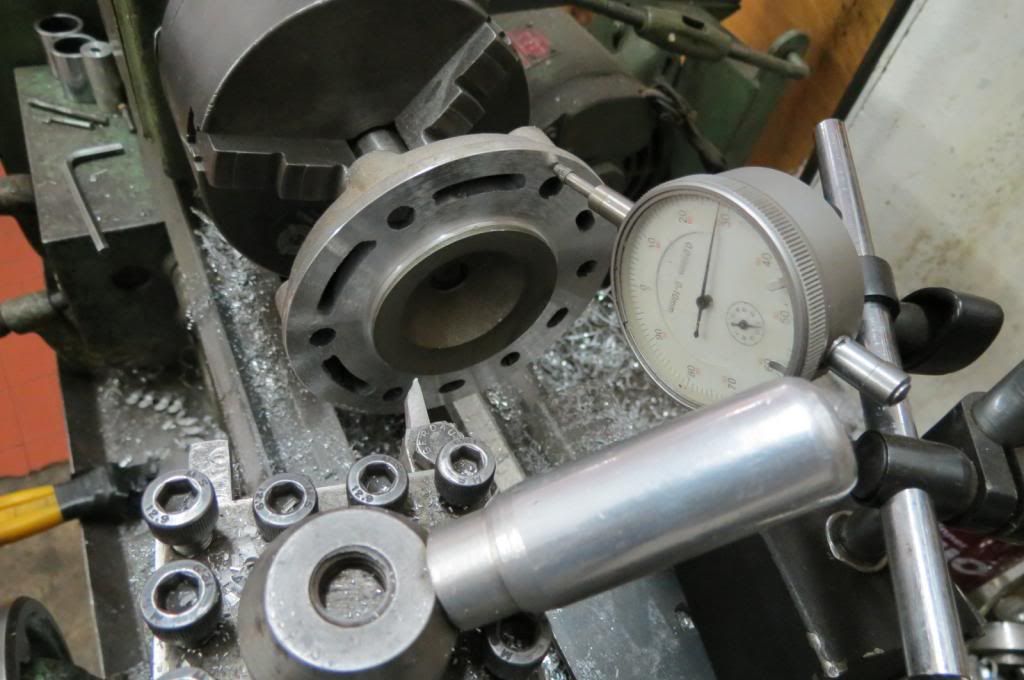

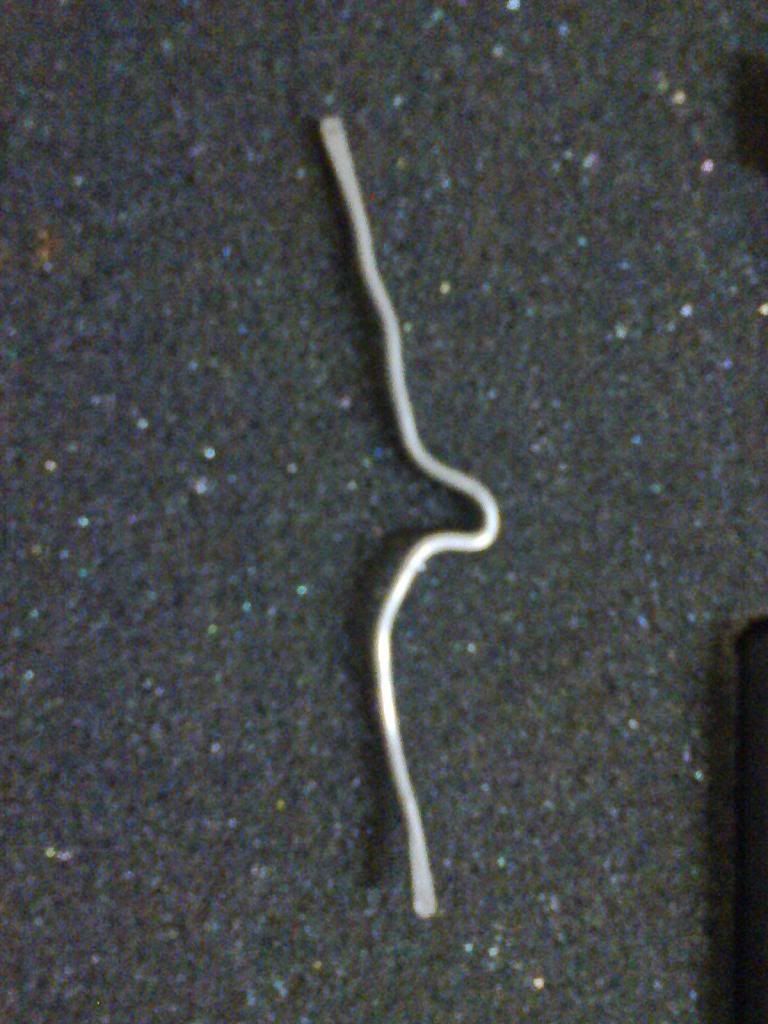

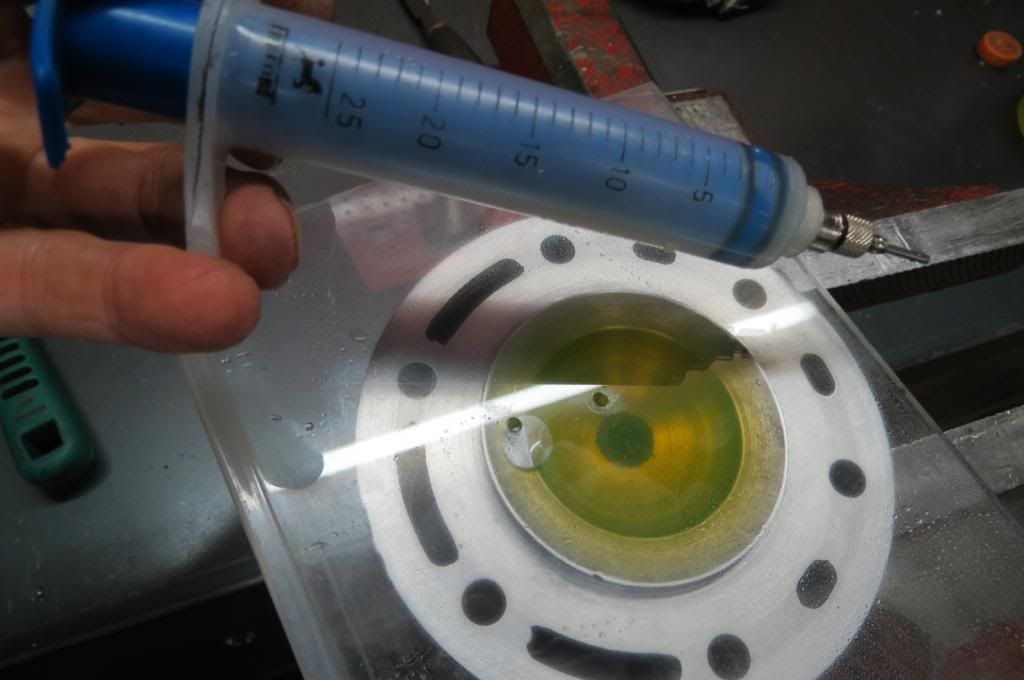

Squish 1,0mm:

Checking the Compression Ratio:

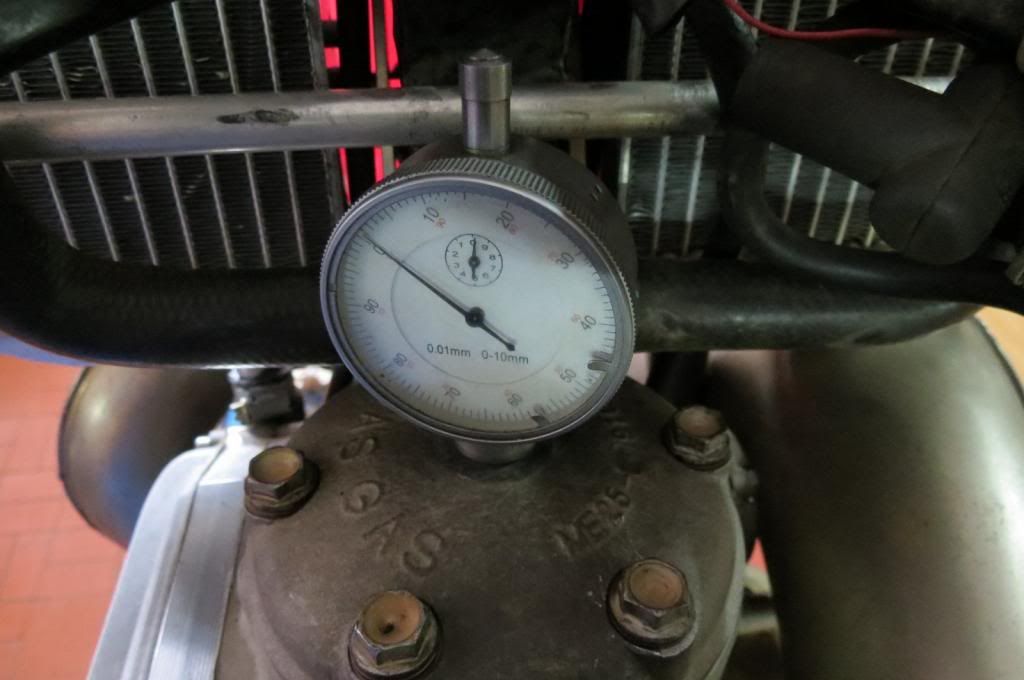

Checking the ignition point:

Height of Slide Idle:

My current settings are as follows:

Needle: # 3 NEDW

Pilot Jet: 48

Main Jet: 175

Screw air: 1.5

Elevation: 60 meters

Temperature: 10th ~ 38th Celsius

Carburetor: PWK AS1

Fuel: 95 octane gasoline, containing 25% alcohol

I really would like to thank my good friend and great mechanic Mr. Dilvo Favretto, who has devoted his time and expertise to improve my dear GasGas EC 250.

The link is from the website of his garage:

dilvoracing.com.br

My name is Leandro, I live in Brazil, and I have a GasGas EC 250 2008. I have this motorcycle since 2010 and during this period I?ve had to manage 2 different problems that have been solved in two different moments.

My bike has never shown a consistant idle, which means the engine use to die after about 10 seconds on idle mode, and also used to die on longer descents or in other technical tracks, where I always had to keep the throttle slightly open to avoid the motor to die. I never thought about the possibility of adjusting the idling rotation into a slightly higher rotation to minimize this problem, because I thought it wouldn?t be nice on riding a bike with a high idle, and that this adjustment would not solve my problems ...

The second problem I was facing was carburetion. The low quality needle that originally came on my bike (N1EF), was excessively ?rich? in its straight part, forcing me to use it in a very low position, because in the contrary, the working up to 1/4 throttle was very rich, causing crashes and rough ?low quality? responses when throttling. The problem of calibrating to low the needle was that from 1/4 to 3/4 throttling, the carburetor has became very impoverished, and the transition from low to medium speed was very abrupt, producing a ?remarkable kick? considering the carburetion changed from rich to lean in such a quick time of throttle.

Seeking a solution for this problem, I searched a lot in this and other related forums, where Ive found several posts about the needles Triple Taper, especially the NE series. I ordered several needles, among them the NECJ, NECW, NEDW and NECH from the U.S.A and after several tests, considering the temperature and humidity variances, because in my area the temperature ranges from 5?C in winter to 40? C in the summer, the needles that best result produced to my riding style are the NECW and NEDW.

With needle exchange the carburetion problem was solved, I loved the performance of the engine with these new needles. But the problem of idle remained the same, in other words without idle .... So, as I had worked in many other things that could influencing the instability of idling, such as the reed valves, the crankshaft seals, the fake air intake, the level of the float into the carburetor. I changed even the swap OEM throttle cable for a MotionProT3 - that by being much longer allows a better free play, I decided to talk to my good friend and excellent mechanical and engine adjuster called Dilvo Favretto about the change in the Squish band, who confirmed that this should be an excellent change to be done, because it would be optimize the engine performance.

Agreed on the services, I took the bike to his workshop, and it was verified the original Squish band and the result was really scary ...2.4 mm! Once changes were done, the new measure of the squish band was 1.00 mm.

As we were with the engine partially opened, we took this opportunity to change the height of the cylinder, using 2 base gaskets, being one of 0.4 mm and other of 0.8 mm. With these measures, the windows stayed 0.5 mm below the top of the piston.

Another important check we did, was the check of the ignition timing. My bike was in 1.3mm BTDC. We have advanced to 1.6mm BTDC and the result was excellent, idling more stable and with better answers to the throttle.

After all this changes, we had just to test the bike on the fields?

The result could not be better, with the new adjustment of Squish band, the responses from the engine were much faster, the engine started to work in a ?clean way? even the noise was different, more aggressive, looking like the noise of a Motocross 2T. Now, any small adjustment of the air screw is being noticeable, much different than before.

I?m going to add some pics about the job we did.

Disassembling of the Head

Notice in the pictures below the excellent condition of the piston when disassembling. The piston had 64 hours of use, and the wear of this period was 0.002 mm. Since ever, the oil used is Motul 800 in the ratio of 1.5%.

Head before setting the squish band:

After work was done:

Squish 1,0mm:

Checking the Compression Ratio:

Checking the ignition point:

Height of Slide Idle:

My current settings are as follows:

Needle: # 3 NEDW

Pilot Jet: 48

Main Jet: 175

Screw air: 1.5

Elevation: 60 meters

Temperature: 10th ~ 38th Celsius

Carburetor: PWK AS1

Fuel: 95 octane gasoline, containing 25% alcohol

I really would like to thank my good friend and great mechanic Mr. Dilvo Favretto, who has devoted his time and expertise to improve my dear GasGas EC 250.

The link is from the website of his garage:

dilvoracing.com.br