how do i get it out? I took off the bolt on the left side (as though your sitting on the bike) and so now i see the threads and on the right side theres is what looks like the axle but there is a small piece of metal welded infront of it. I am not the original owner so im not sure if thats oem. but anyways how do i get the swingarm axle out?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

swingarm axle

- Thread starter wheels7

- Start date

fury1

New member

what year is the bike? if it hasnt been done for a few years,be prepared for a battle,I used a brass drift on mine with plenty of penetrating oil for a few days and it finally let go and slid out,after some hammering,some guys have other ways to di it,but mine came out and didnt need another way,good luck!

Yup. Just take the nut off and drift the bolt out. The weld just keeps the axle from spinning when you're turning the nut.

If it doesn't want to come out then your bearings are probably toast. Heat, penetrating oil, patience, a dead-blow hammer.

Maybe an impact wrench with a socket that won't damage the end of the bolt (although the bolt may be junk anyway).

Sometimes loosening the motor mounts helps by taking a bit of torque off the axle.

If it doesn't want to come out then your bearings are probably toast. Heat, penetrating oil, patience, a dead-blow hammer.

Maybe an impact wrench with a socket that won't damage the end of the bolt (although the bolt may be junk anyway).

Sometimes loosening the motor mounts helps by taking a bit of torque off the axle.

Nope. Hit the end that the nut came off. The axle comes out the brake side.so it comes out on the same side that the bolt was on? the left if your sitting on the bike?

I'm assuming you've removed the lingage. That could also cause a bit of resistance.

MattR

Super Moderator

STOP.... DO NOT GRIND THE WELD AWAY!!!

Hopefully, I stopped you in time.

BrianVT is correct. If you look carefully on the right side of the bolt, you will see the head is D-shaped. The weld needs to be there in order to keep the bolt from rotating while you torque the nut (on the leftside). Note: on my bike, the weld makes a very close fit with the bolt head. This is no issue during disassembly, but when you reassemble it... it can be a bit temper-mental about getting the bolt head in relation to the weld.

Undo the nut on the left and put a drift/socket against the leftside bolt face. Now, whack it with a dead-blow hammer and it should move the bolt towards the rightside and out. After you get the bolt out, the weld will then make complete sense to you.

Hopefully, I stopped you in time.

BrianVT is correct. If you look carefully on the right side of the bolt, you will see the head is D-shaped. The weld needs to be there in order to keep the bolt from rotating while you torque the nut (on the leftside). Note: on my bike, the weld makes a very close fit with the bolt head. This is no issue during disassembly, but when you reassemble it... it can be a bit temper-mental about getting the bolt head in relation to the weld.

Undo the nut on the left and put a drift/socket against the leftside bolt face. Now, whack it with a dead-blow hammer and it should move the bolt towards the rightside and out. After you get the bolt out, the weld will then make complete sense to you.

fury1

New member

follow the linky--http://www.smackovermotorsports.com/bb/showthread.php?t=983 lots to read,but at least you know what is needed,dont give up!

MattR

Super Moderator

Wheels7,

Just double-checking, but the only thing attached at this point is the swingarm. Correct?

It also helps the first time to remove the rocker arm and lower bolt on the rocker arm supports. This ensures nothing is causing additional constraints... only the swingarm bolt is left.

Here is a pic showing the other bolts to remove on the rocker arm and supports. Note: This picture was taken during reassembly (just before putting the swingarm back on).

Just double-checking, but the only thing attached at this point is the swingarm. Correct?

It also helps the first time to remove the rocker arm and lower bolt on the rocker arm supports. This ensures nothing is causing additional constraints... only the swingarm bolt is left.

Here is a pic showing the other bolts to remove on the rocker arm and supports. Note: This picture was taken during reassembly (just before putting the swingarm back on).

Attachments

You'll get it. I went through it with a bike years ago.

Swingarms cannot be neglected. I went 1 1/2 years on this one. Too long for the wet year we had. It came apart without much fuss but the swingarm bearings are toast. Close call. The linkage bearings are fine though.

I'll not let it go more than 6 months again. Especially since I ride snow/ice too.

Swingarms cannot be neglected. I went 1 1/2 years on this one. Too long for the wet year we had. It came apart without much fuss but the swingarm bearings are toast. Close call. The linkage bearings are fine though.

I'll not let it go more than 6 months again. Especially since I ride snow/ice too.

Last edited:

matt, both of those bolts are removed. I have been pounding on this thing with an air hammer and my mallet. its not budging at all. ive been using some penetrating oil but to no avail. its really becoming a pain i guess what it really needs is time. i got the idea of drilling into the back of the cases in order to get to the axle then putting some lube in there and when i was done i would just put a zirk fitting on so i could then lube everything later without removing any thing. does this sound plausible? well i guess ill just keep hammering and order up a new axle because the end of this one i mangled.

Can't hurt. I'd still do regular tear-downs even with the zirks just so you don't end up in the same predicament again. Once a year is probably safe with good grease (see other posts about marine moly paste).i got the idea of drilling into the back of the cases in order to get to the axle then putting some lube in there and when i was done i would just put a zirk fitting on so i could then lube everything later without removing any thing.

MattR

Super Moderator

i got the idea of drilling into the back of the cases in order to get to the axle then putting some lube in there and when i was done i would just put a zirk fitting on so i could then lube everything later without removing any thing.

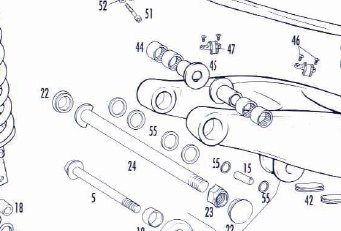

When you say "cases"... do you mean the central portion of the engine case shown in my previous picture. If so, that would not help. This portion acts as a spacer and is a clearance fit to the swingarm axle. The axle only contacts the bushings (T-shaped components) located on each side of the swingarm. I attached a pic below from the parts catalog to help illustrate.

As shown in the pic:

The needle bearings (44) are pressed into the swingarm. The bushings (45) get clamped between the frame and engine case by the swingarm axle (24). This allows the needle bearings to rotate about the bushing during suspension travel. Therefore, the swingarm axle is really a clearance fit to all items... bushings, engine case, rocker arm supports, etc.. The swingarm axle only provides the clamp load and alignment to keep everything functioning.

I would guess the swingarm axle is seized to the bushings (45). Hopefully, the bushings are not seized to the needle bearings. This would mean the bearing races have been rotating within the swingarm (i.e., no longer a pressfit). This would not be good.

When you finally get it apart and ready to put back together... put some anti-seize or grease on the axle. Do this same thing with front and rear wheel axles. In all of these areas, the axles are only providing clamp load and are not the roller bearing/needle bearing surface (the races/bushings are doing this function).

Attachments

Similar threads

- Replies

- 5

- Views

- 651

- Replies

- 0

- Views

- 412

- Replies

- 8

- Views

- 678

- Replies

- 2

- Views

- 181