Sense I am new to GG bikes and I have read probable 12 hours on various things to improve these bikes in this section of the forum it's now time for some questions and I hope you guys can help me out.

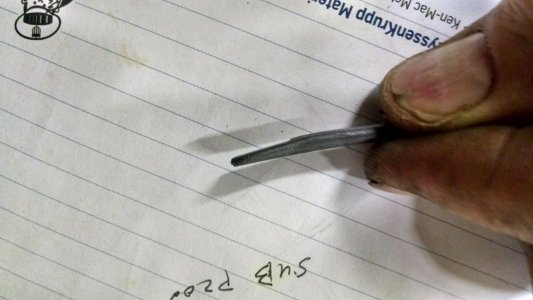

Lets start with squish gap. My 200 has a squish gap of 1.5 to 2.0mm and from checking the solider I would say the squish width is at 8.5mm.

From what I have read it should be in the 1.1 to 1.5mm range for pump gas fuel?? I use 90 octane on (R+ M)/2 octane rating

My cranking compression is 145 PSI after 5 kicks with the throttle at WOT. The top end was rebuilt and has approx 3 hours of riding on it.

I know our 99 YZ250 is at a 180PSI after 5 kicks and it runs just fine on our 90 octane.

Has any one CC'ed there 200 head after correcting the squish either Installed or Flat plated?? And what kind of cranking compression are you getting out of it??

I also just went through my carb to see what it has for jetting.

180 Main Jet

42 pilot jet, Air screw is set at 1.5 turns out

#7 slide cutaway

CCL needle in #4 clip

Thanks in advance.

Lets start with squish gap. My 200 has a squish gap of 1.5 to 2.0mm and from checking the solider I would say the squish width is at 8.5mm.

From what I have read it should be in the 1.1 to 1.5mm range for pump gas fuel?? I use 90 octane on (R+ M)/2 octane rating

My cranking compression is 145 PSI after 5 kicks with the throttle at WOT. The top end was rebuilt and has approx 3 hours of riding on it.

I know our 99 YZ250 is at a 180PSI after 5 kicks and it runs just fine on our 90 octane.

Has any one CC'ed there 200 head after correcting the squish either Installed or Flat plated?? And what kind of cranking compression are you getting out of it??

I also just went through my carb to see what it has for jetting.

180 Main Jet

42 pilot jet, Air screw is set at 1.5 turns out

#7 slide cutaway

CCL needle in #4 clip

Thanks in advance.