NHtrailrider

New member

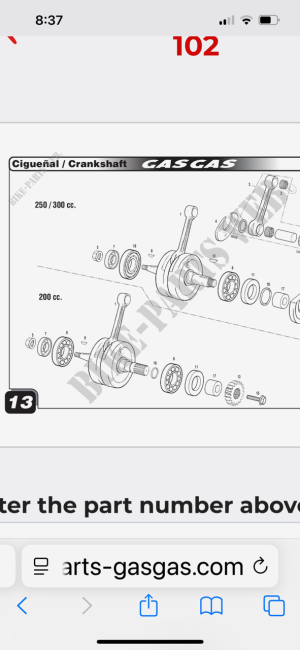

I have a 2005 EC200 that has eaten two RH crank seals in less than 1 hour of run time. The bike is burning trans oil.

I replaced the inner o-ring on the crank both times. The first replacement I used the all-balls kit and the second I used an OEM seal. The seal spacer did have a small groove in it that I sanded down smooth.

The bike has a fresh replated top end and new piston. It starts easy and idles well. It smokes excessively when on the gas in the mid-top range of the throttle. Both PV and crankcase vent hoses are open and unclogged.

I am now thinking it could be the center case gasket? Would a leaking center case gasket allow trans oil into the combustion chamber? Am I missing something or does anyone have any ideas?

I replaced the inner o-ring on the crank both times. The first replacement I used the all-balls kit and the second I used an OEM seal. The seal spacer did have a small groove in it that I sanded down smooth.

The bike has a fresh replated top end and new piston. It starts easy and idles well. It smokes excessively when on the gas in the mid-top range of the throttle. Both PV and crankcase vent hoses are open and unclogged.

I am now thinking it could be the center case gasket? Would a leaking center case gasket allow trans oil into the combustion chamber? Am I missing something or does anyone have any ideas?