While the parts supply is still good, I decided to check some things on the gasser because I'm going to hang on to it even though I'm going to buy another brand for 2016. The bike only has about 150 hrs. Please feel free to comment on any of the procedures or parts.

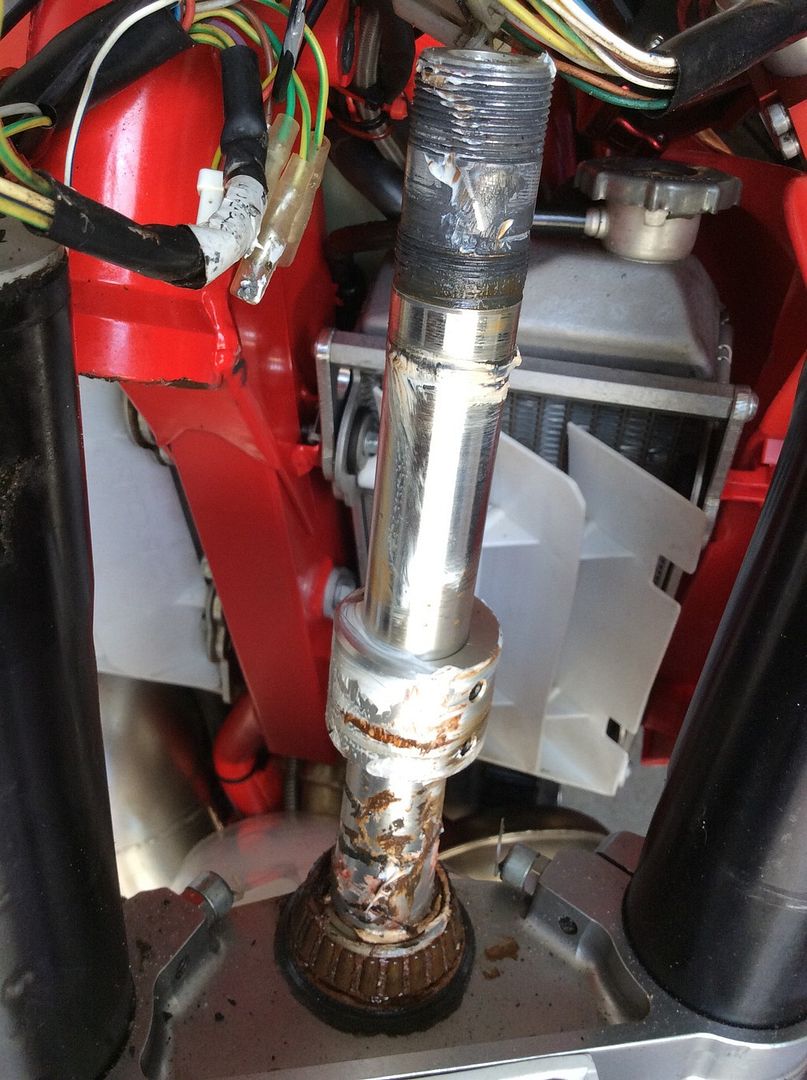

First, I did the swingarm bearings and suspension link bearings. I was surprised that the the swingarm bearings had a lot of crap in them. However, when they cleaned up fine. I pulled all the pins out, cleaned everything up then repacked them with salt water proof grease. Be careful not to lose any pins in the disassembly. The bushings didn't look too great so I replaced them.

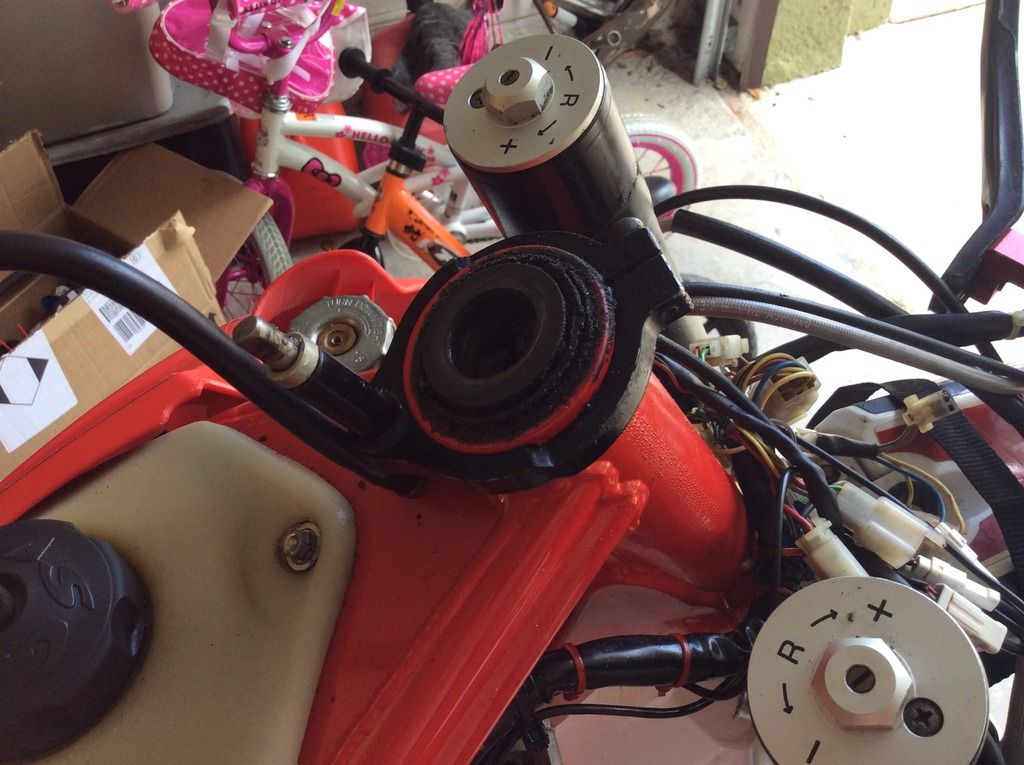

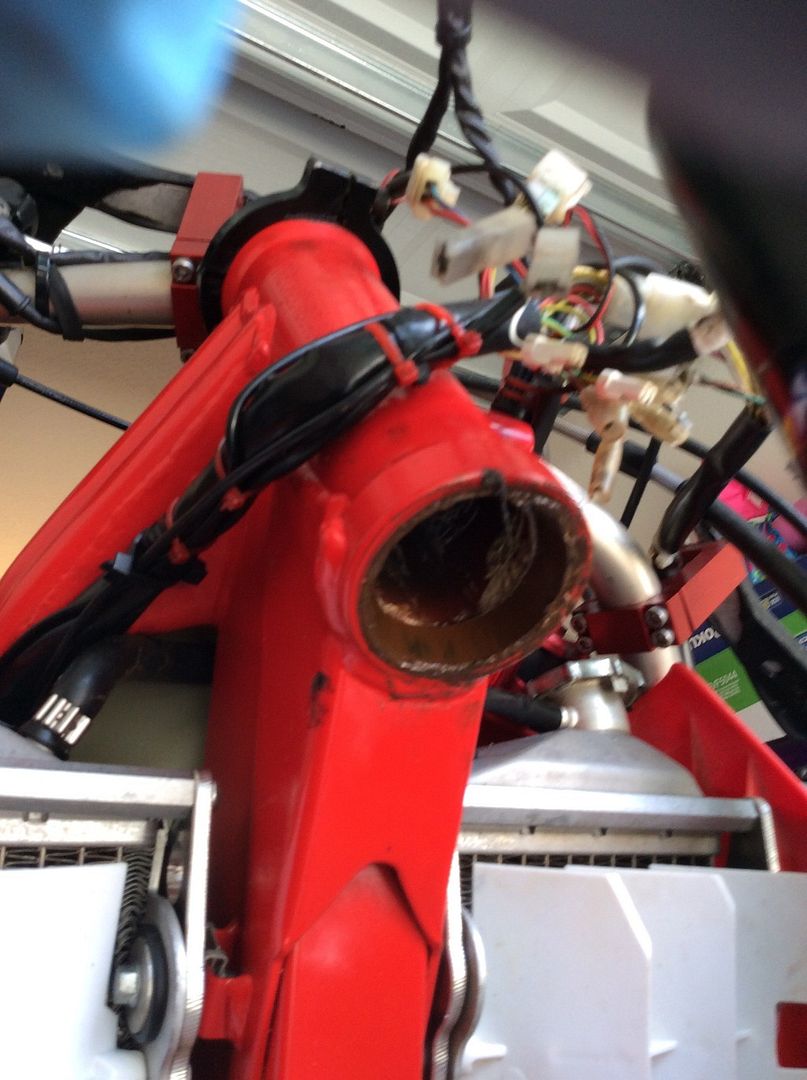

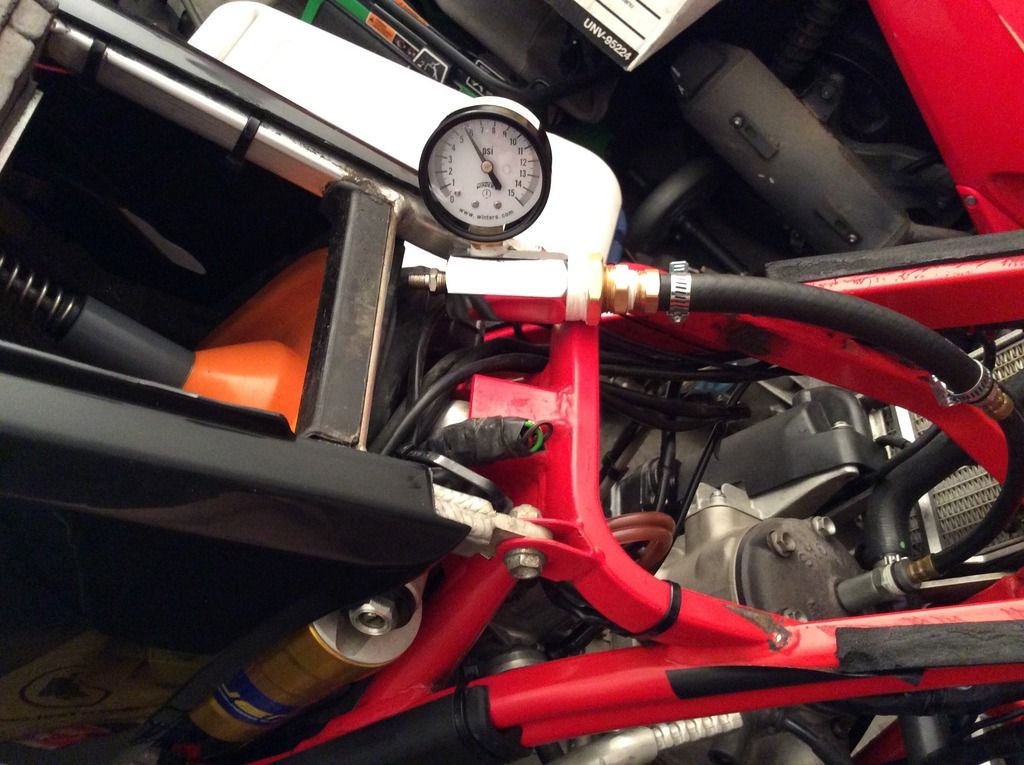

Here is the gasser before the I started taking things apart.

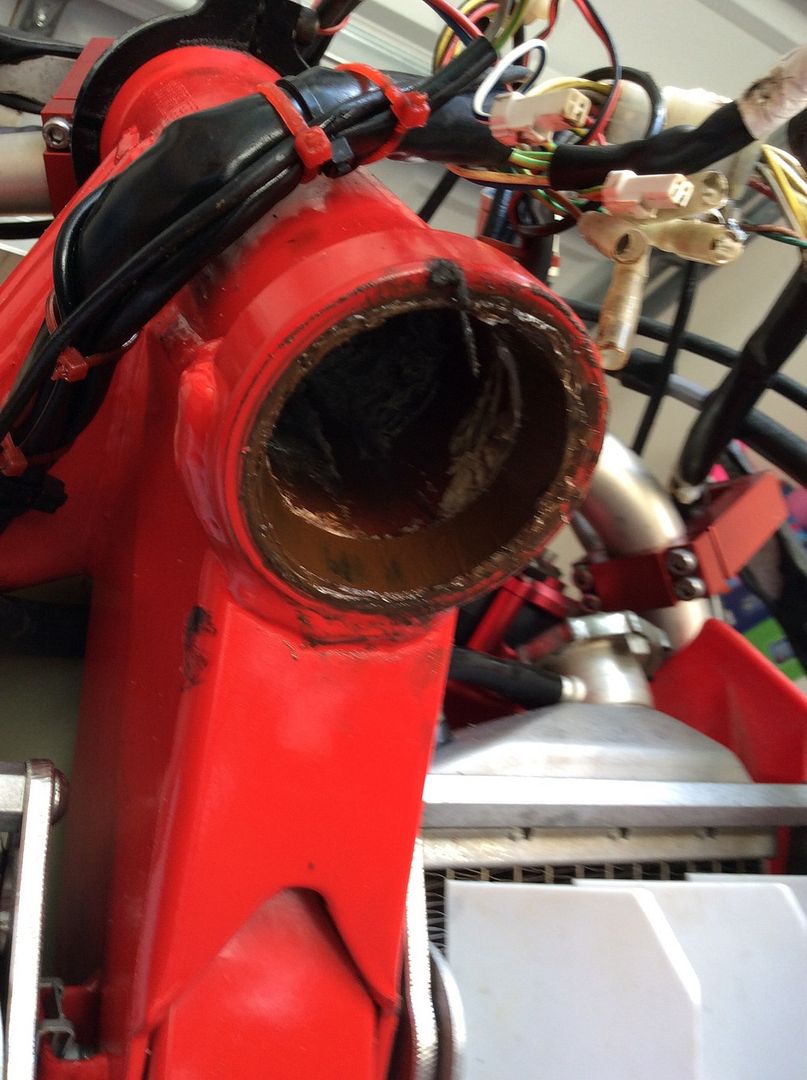

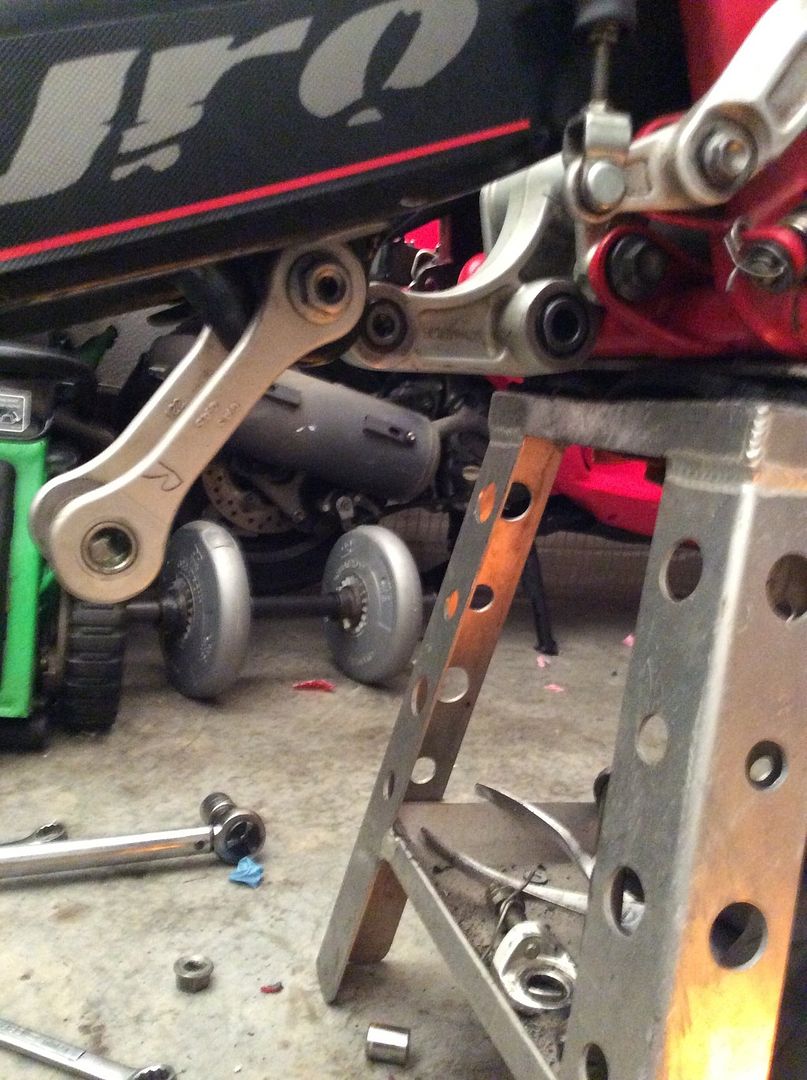

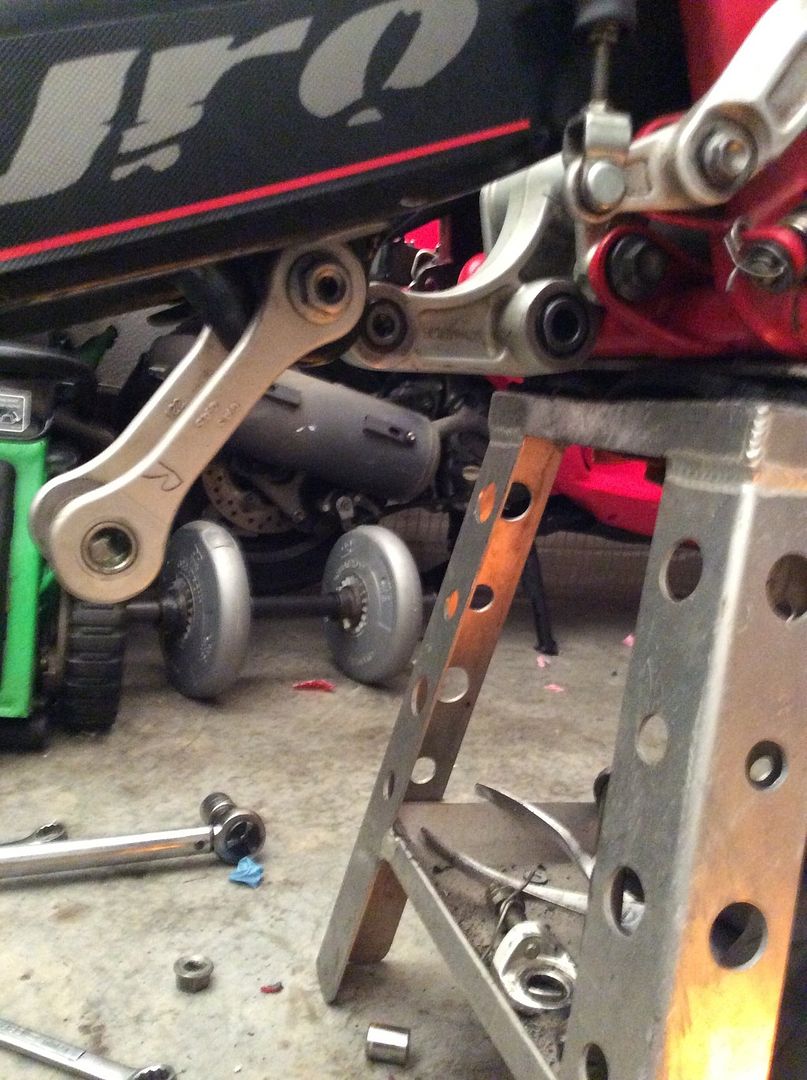

Here is the rear link,

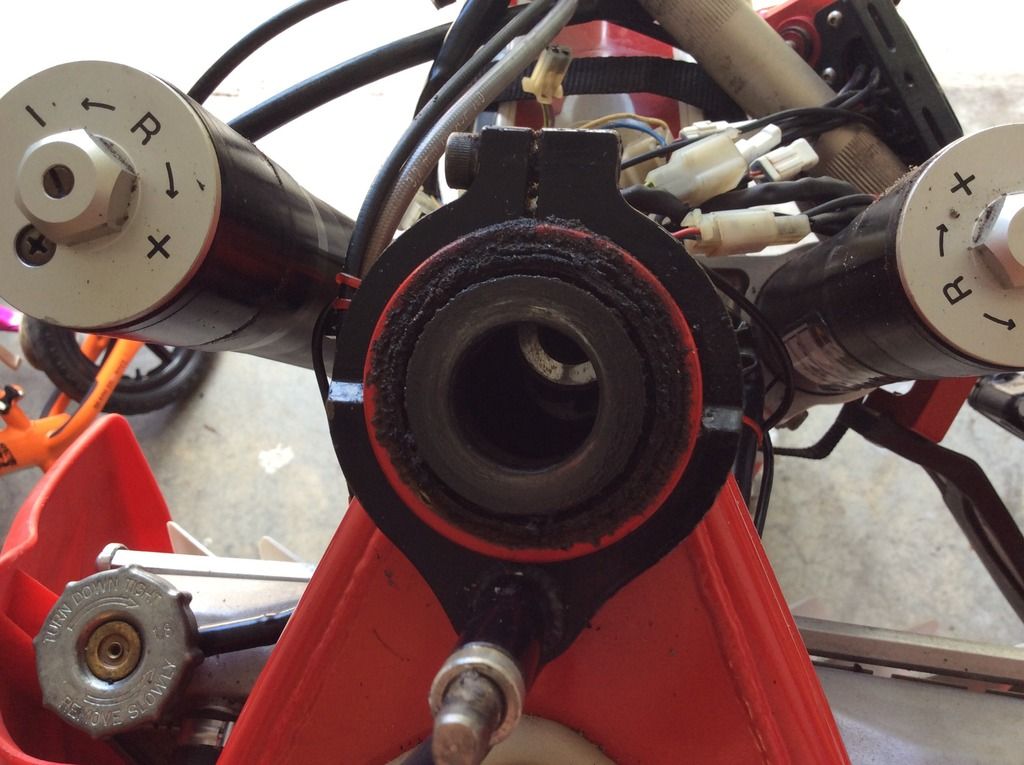

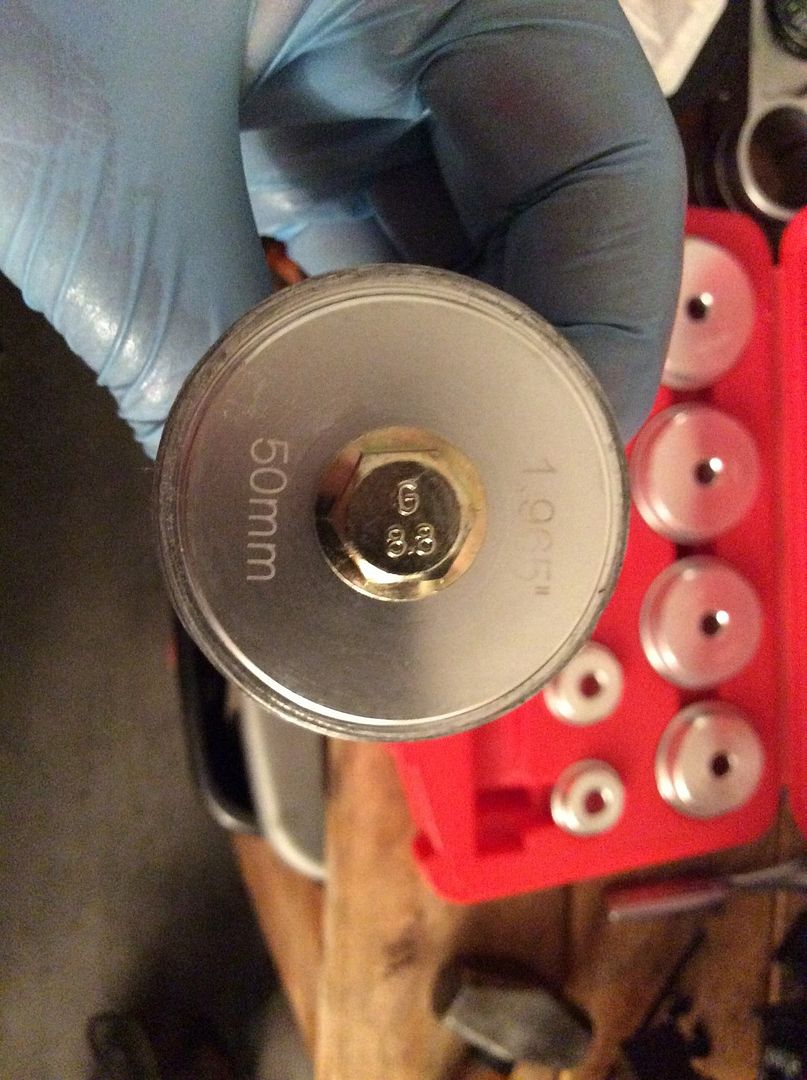

Swingarm bearings full of junk.

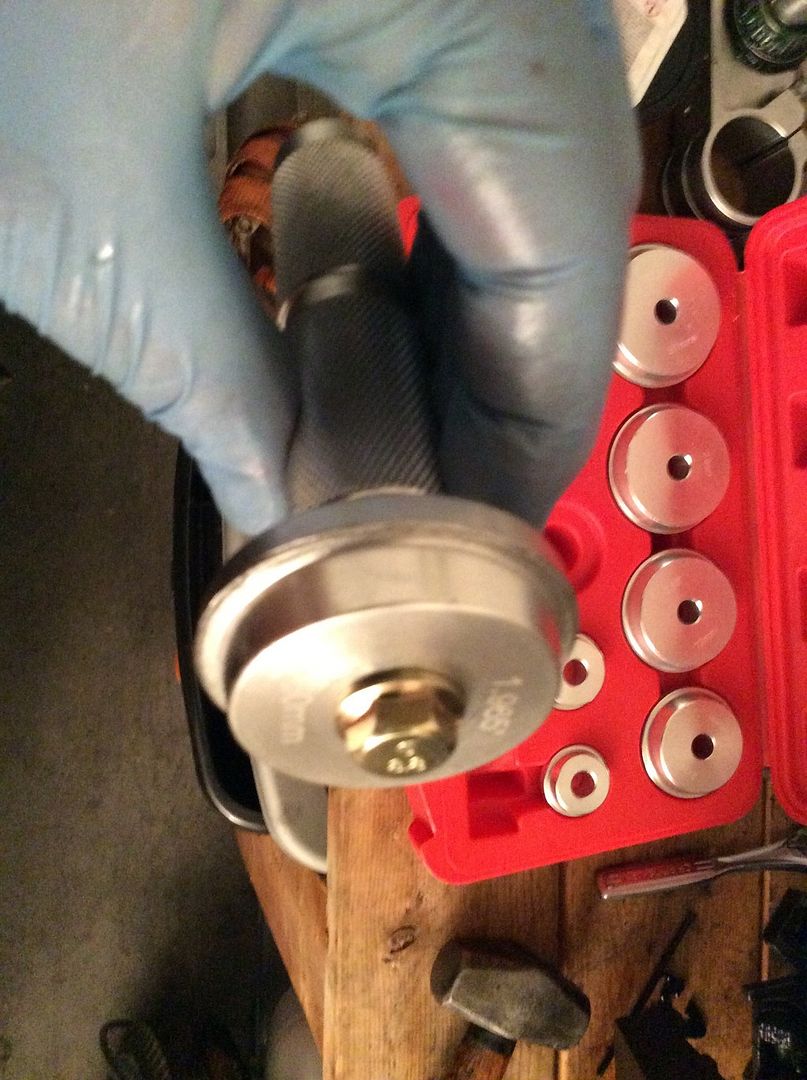

Here are the bushings, new one on the left and old one on the right.

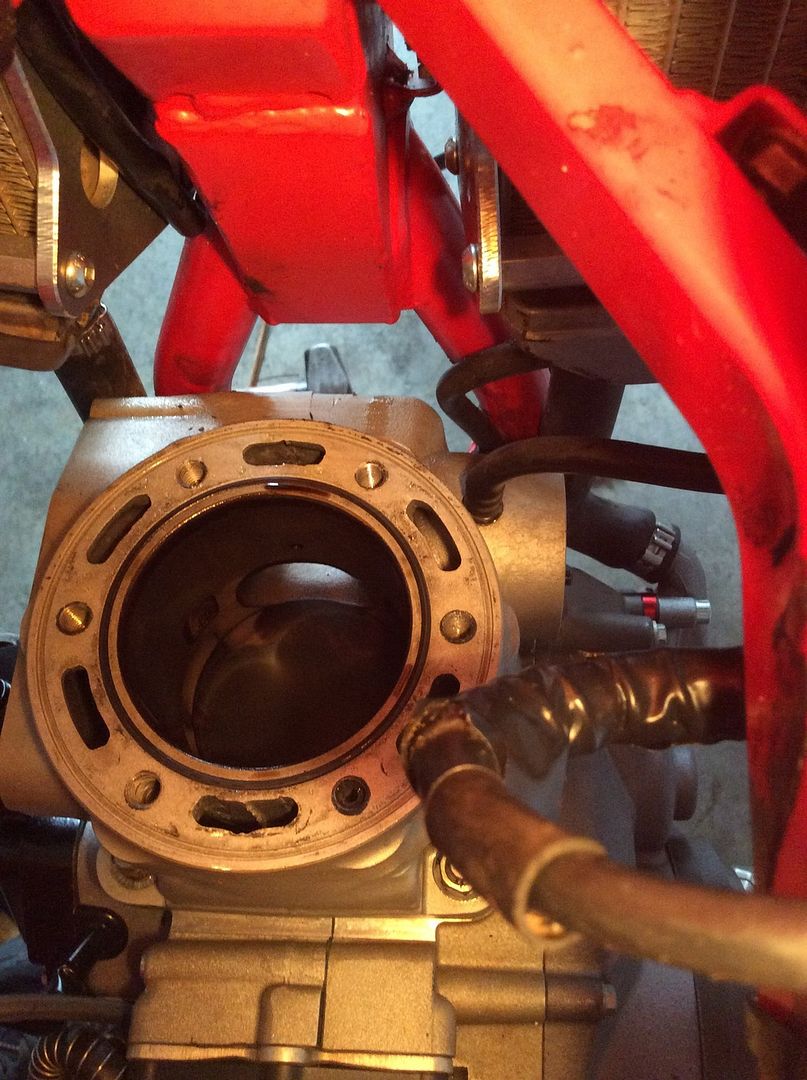

Here is the suspension bearing before cleanup,

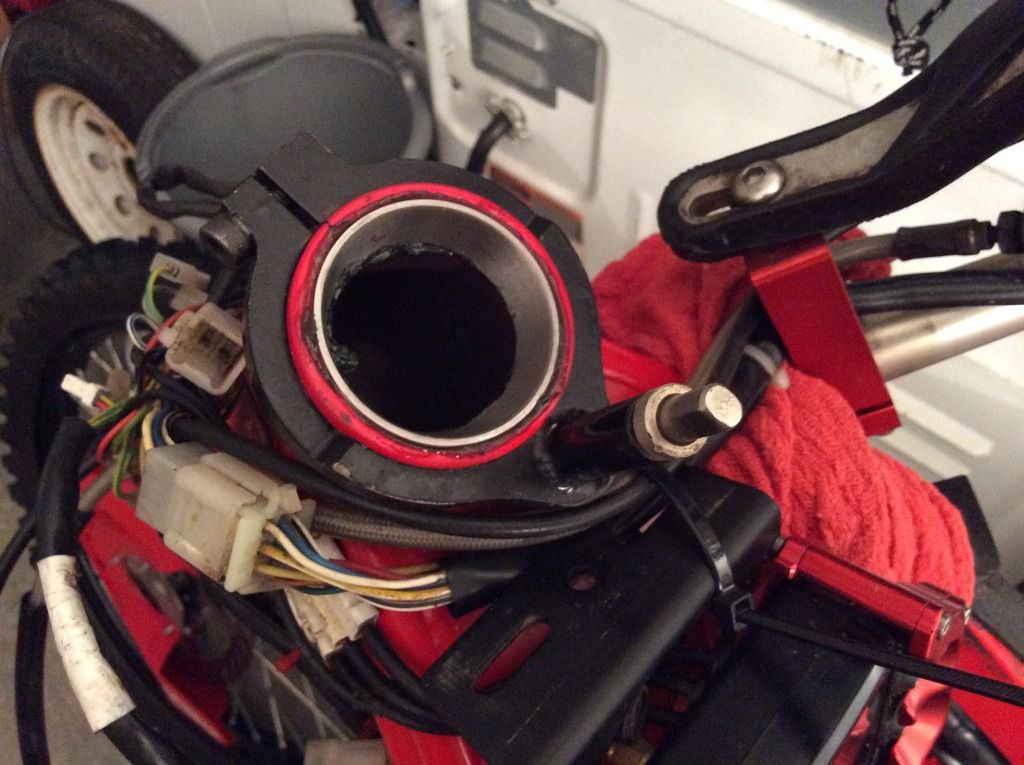

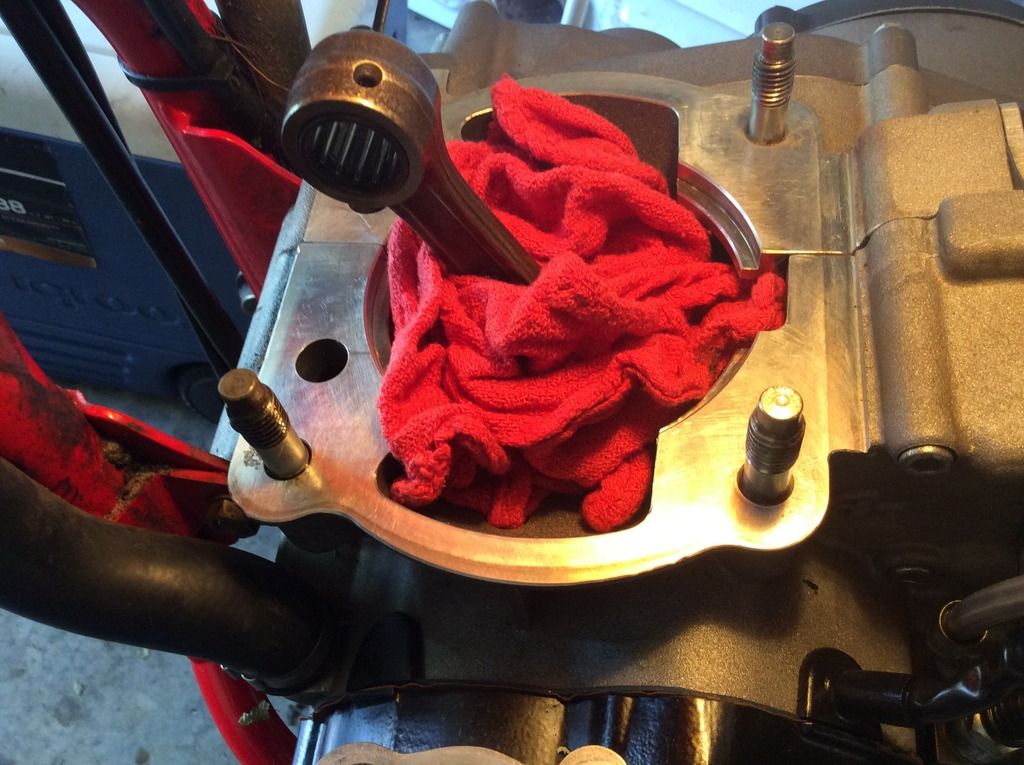

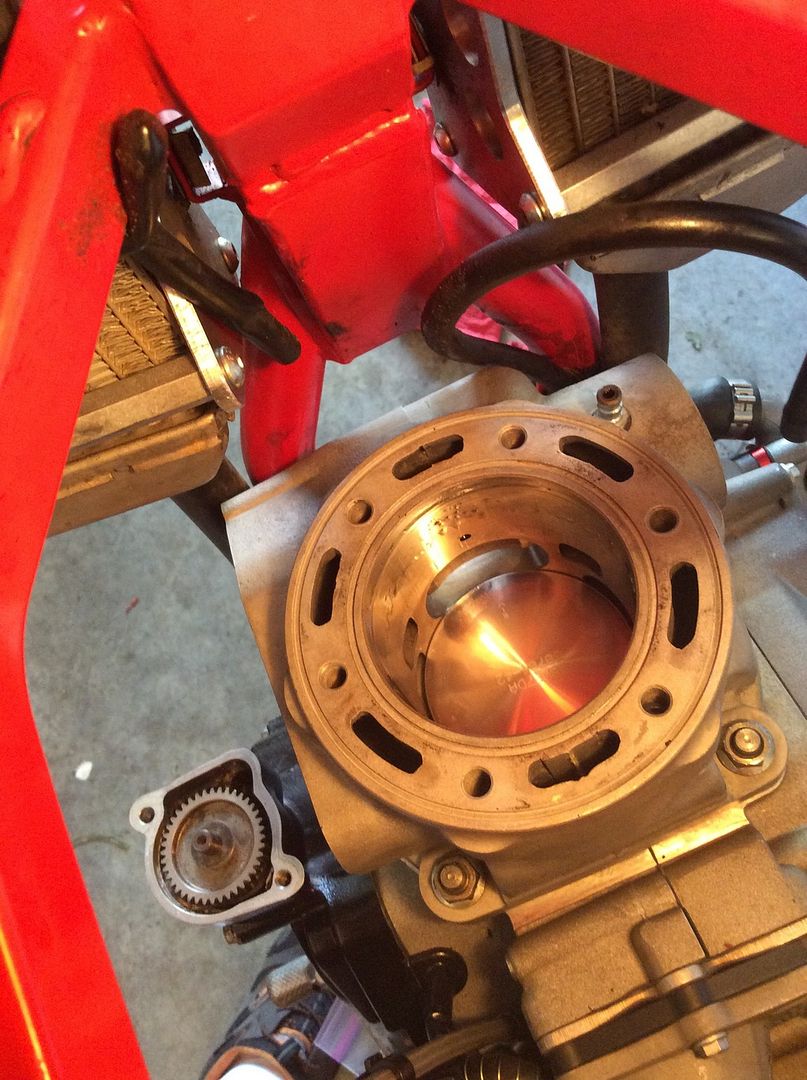

After the cleanup, this is how they looked,

Suspension bearing after cleanup,

First, I did the swingarm bearings and suspension link bearings. I was surprised that the the swingarm bearings had a lot of crap in them. However, when they cleaned up fine. I pulled all the pins out, cleaned everything up then repacked them with salt water proof grease. Be careful not to lose any pins in the disassembly. The bushings didn't look too great so I replaced them.

Here is the gasser before the I started taking things apart.

Here is the rear link,

Swingarm bearings full of junk.

Here are the bushings, new one on the left and old one on the right.

Here is the suspension bearing before cleanup,

After the cleanup, this is how they looked,

Suspension bearing after cleanup,

Last edited: