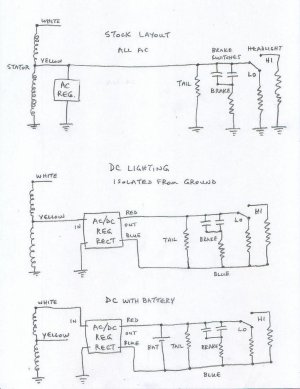

I don't know what to offer at this point. Maybe the next step is to put in an aftermarket full wave rectifier and unground all of the lighting. The stator, CDI and coil remain grounded as normal. The old regulator is removed.

Input to the new reg/rect is yellow and ground. Output from the reg/rect is DC on red and blue wires. Red is used as positive and goes to the headlight switch. From there power goes to the headlight as normal.

The original ground wires at the headlight and tail light are disconnected and moved to the new blue wire. This means the lighting is not frame/chassis grounded. It only gets DC negative via the reg/rect blue wire (we are isolating/floating the reg/rect output by doing this).

The tail light can be connected to the new red all the time. The brake light switch will be connected to the new red wire and the switch output will be connected to the brake light filament.

No battery is needed. If a battery is added, then white and ground can power the reg/rect so the voltage is a bit higher and will charge the battery.

Just to recap, the stator has three connections: engine/frame ground plus yellow OR white wire. Yellow = most of the windings, white = all of the windings.