RockefellerGG

New member

I haven't seen a complete rebuild or walk through on the forum. Maybe I didn't search hard enough. Maybe this will be over-simplified, but I thought it might help someone who needed some motivation or confidence booster.

This EC250 belongs to a friend and fellow forum member. He was riding it a few weeks ago when the engine seized up. While washing it down, he noticed that the carb-to-air boot was disconnected. Here it goes:

Tonight, I'll start with the top end:

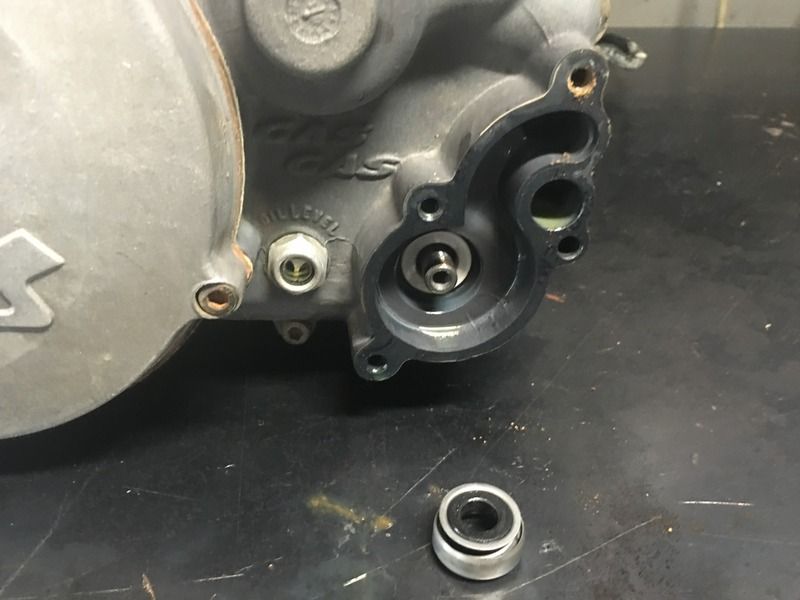

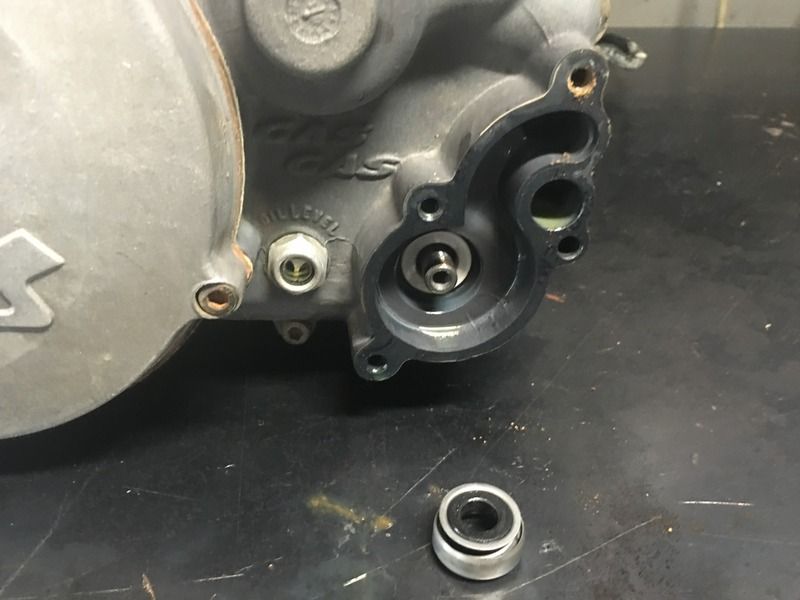

I started by removing the water pump cover:

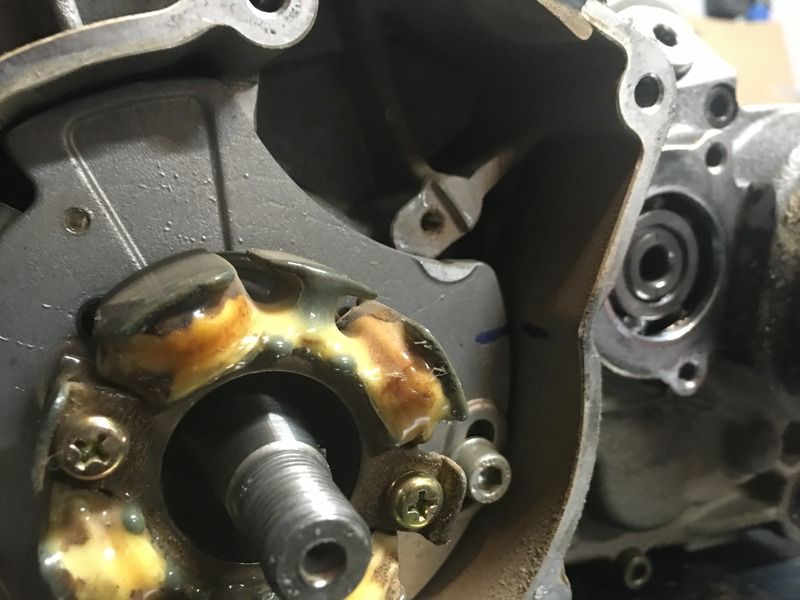

The water pump impeller was seized to the bolt:

Gently pried out the shaft seal:

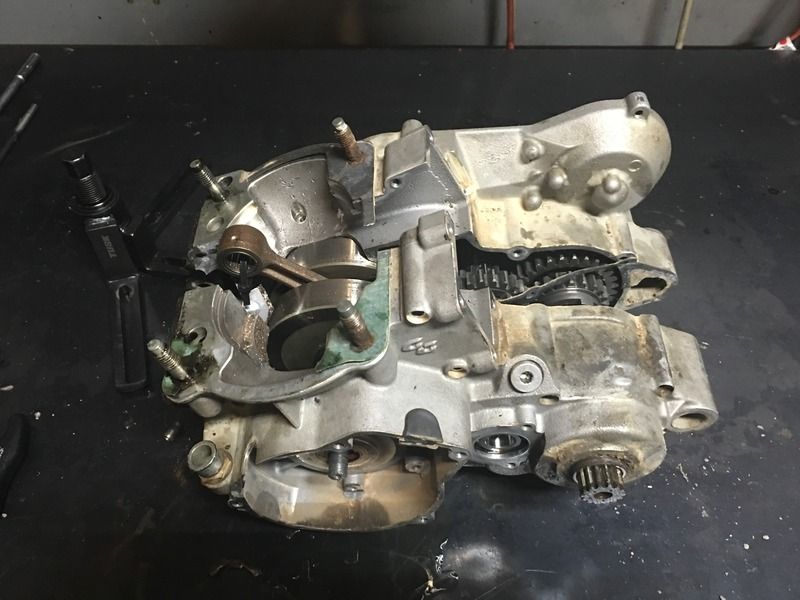

Remove the clutch cover:

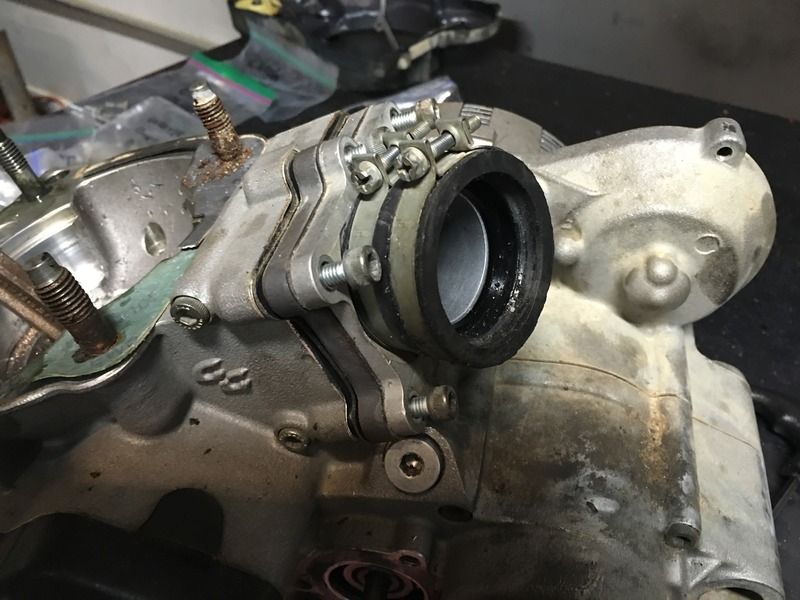

Remove the right side power valve cover:

Removed the kick start lever:

Removed the shifter:

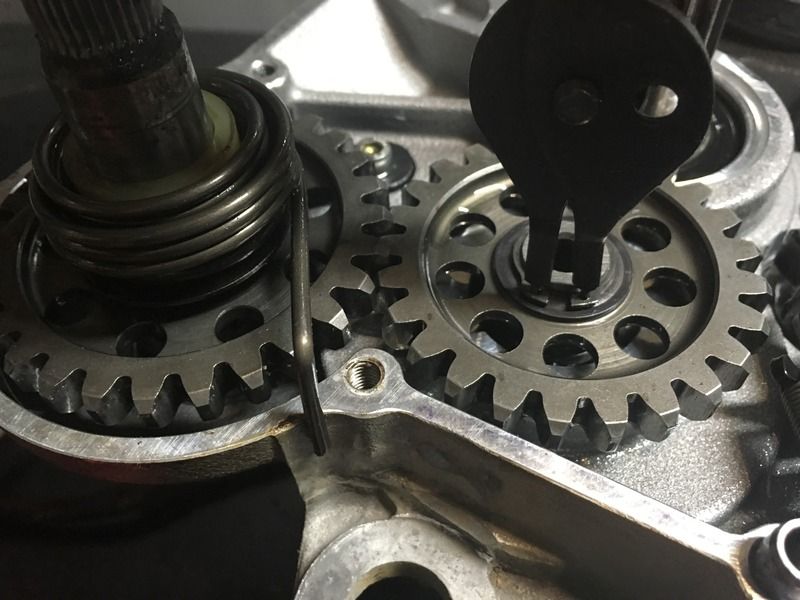

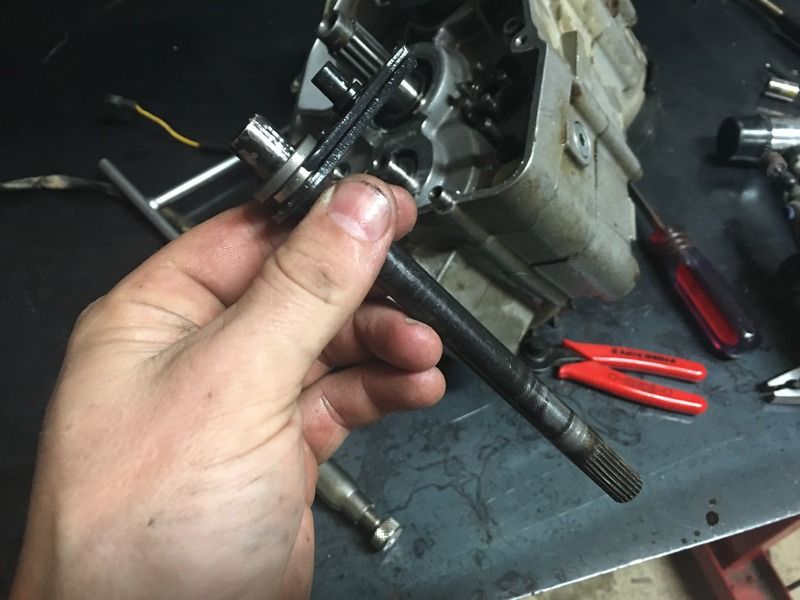

Remove the 6 bolts that hold the right side cover on. Gently pull that cover off:

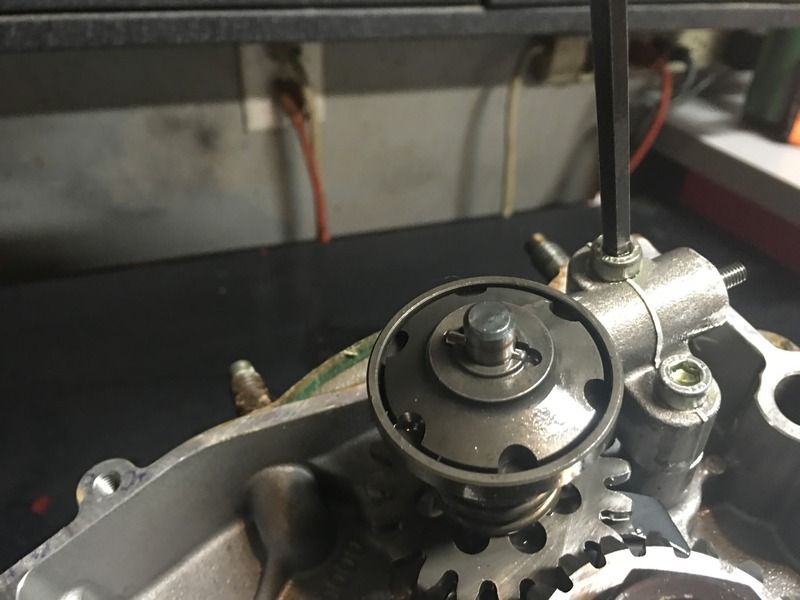

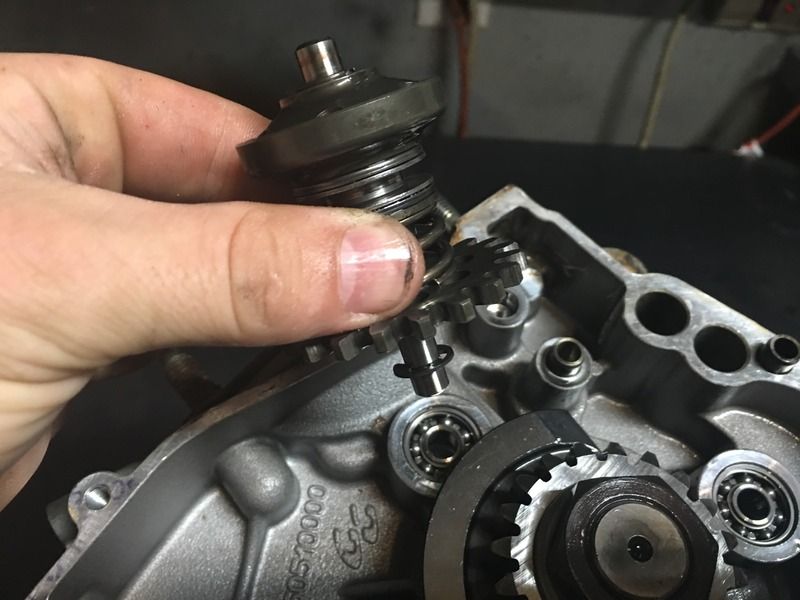

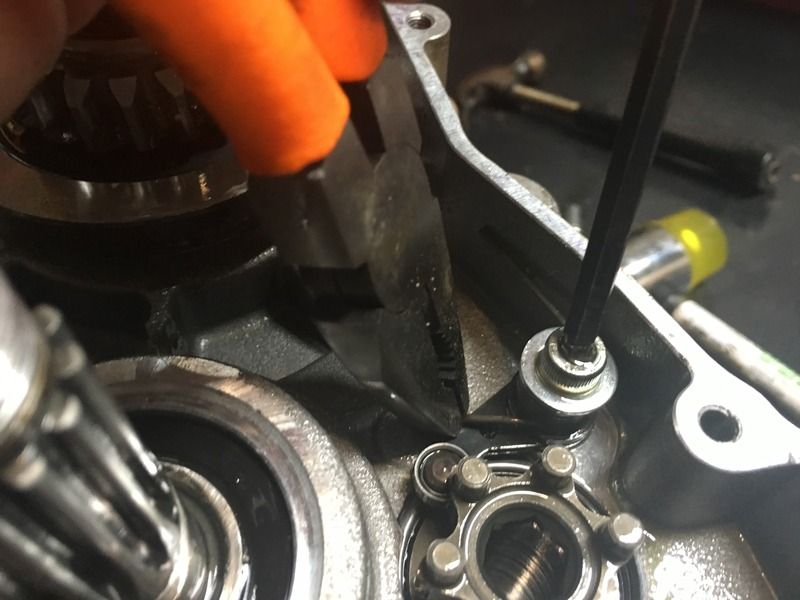

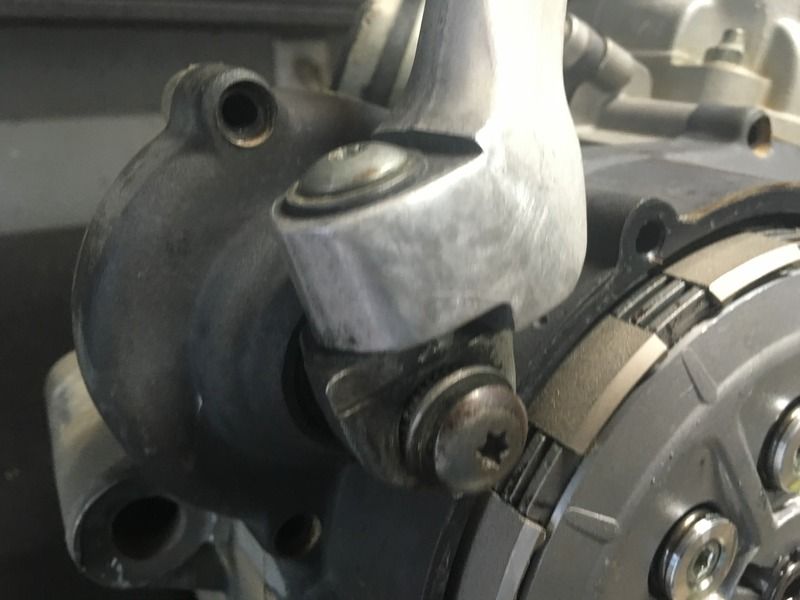

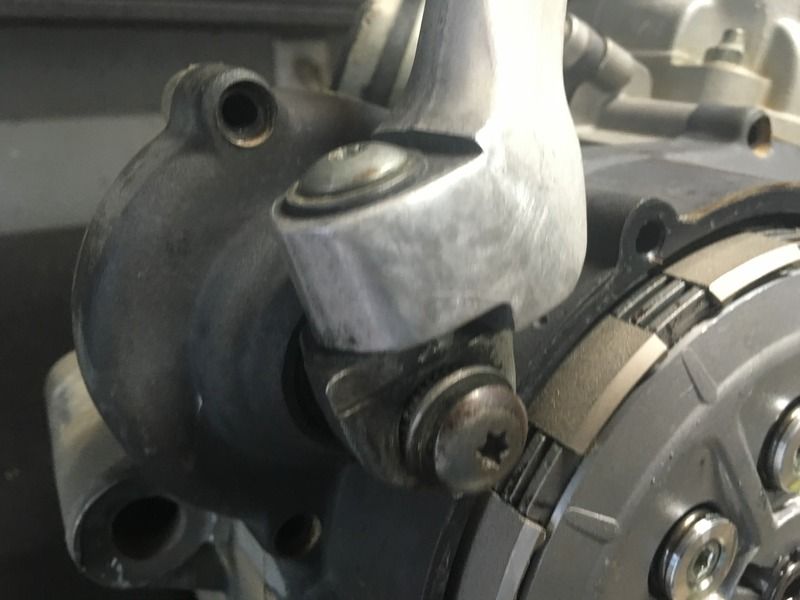

Removed the lower nut that retains the power valve lever arm:

Removed the upper nut that retains the power valve lever arm:

This EC250 belongs to a friend and fellow forum member. He was riding it a few weeks ago when the engine seized up. While washing it down, he noticed that the carb-to-air boot was disconnected. Here it goes:

Tonight, I'll start with the top end:

I started by removing the water pump cover:

The water pump impeller was seized to the bolt:

Gently pried out the shaft seal:

Remove the clutch cover:

Remove the right side power valve cover:

Removed the kick start lever:

Removed the shifter:

Remove the 6 bolts that hold the right side cover on. Gently pull that cover off:

Removed the lower nut that retains the power valve lever arm:

Removed the upper nut that retains the power valve lever arm:

Last edited: