I sent a list of replacement parts and work needing to be done to Hall's Cycles in Springfield, IL. I've had good luck with them in the past and they will continue to get my business. The packaging all says gofasters on them... so I guess they all came through the dealer network. I bet I could have sourced all the parts individually, for less, but it was nice to send them a box of beat up parts and have a box containing all the good stuff in one shot:

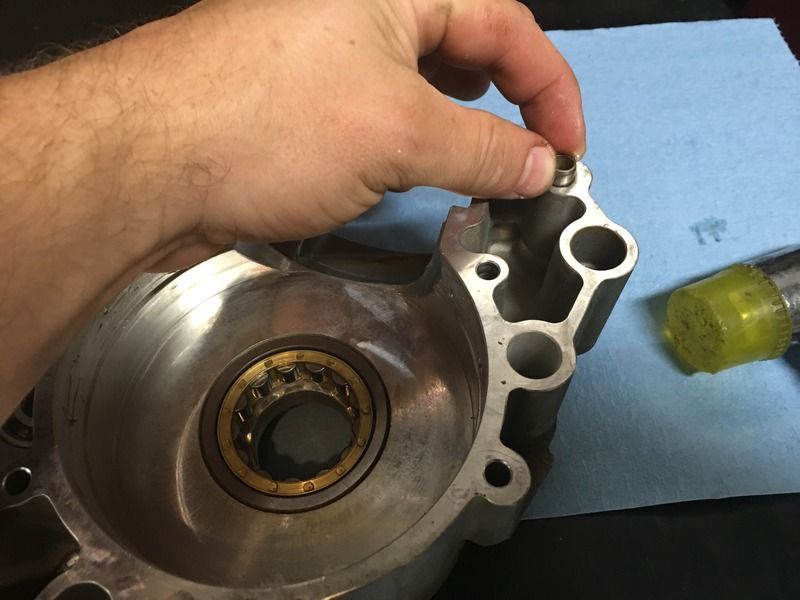

Crank Bearings:

WORL: NJ206 EM C4 ME250112013 $42.99

KOYO: 63/28C4 ME20912006 $74.99

Crank Seals:

ME250112009 $24.50

ME250112008 $34.99

Complete Gasket Set: ME250544100 $134.99

Kick start seal: ME25632021 $12.99

Water pump Seal: ME25610011 $29.99

Selector Seal: ME120136048 $3.25

Primary C/S Seal: ME25636024 $13.50

2 Primary C/S O-rings ME25632025 $9.98

Piston: $189

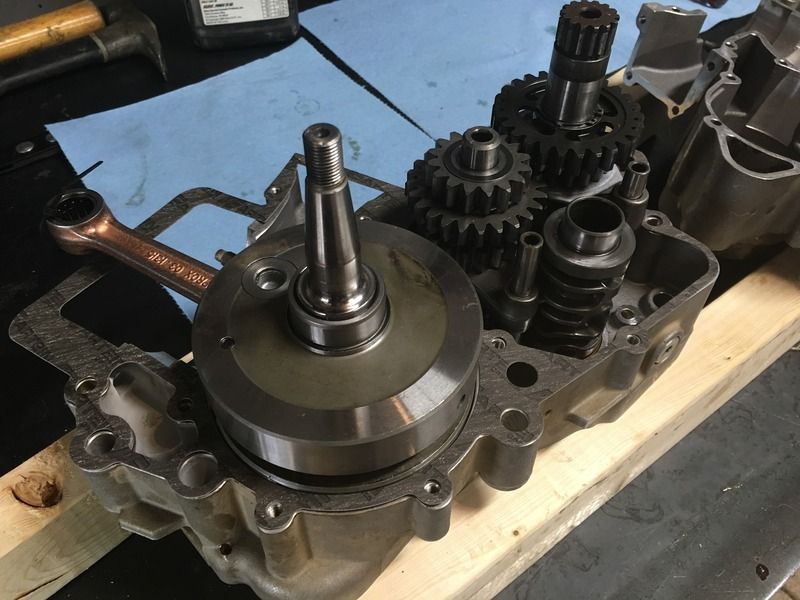

Connecting Rod Kit: 09230125 $106.99

Rebuild and Labor:

Rebuild the crankshaft and balance: $98

Clean up the damage to the head: $35.00

Re-plating the cylinder: $250

Hall's sent this out to a shop called Millenium. It looks fantastic. Pics to come soon.