Jakobi

Super Moderator

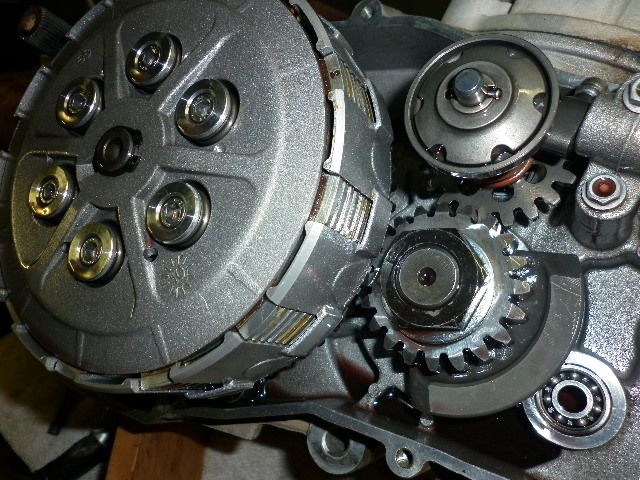

Hello everyone. Here I go again on another learning curve following on from the last one HERE. 110 hours or there abouts has passed since I changed the EC300R to a 250 and I must say I've loved every second of it. The Gasser has been as reliable as a stone and now has 260hrs on the bottom end. I figured it was time for a complete rebuild. I have a large assortment of parts ready which I will probably photograph and post tonight. I may add costings too if anyone shows interest.

Stage 1: Engine Removal

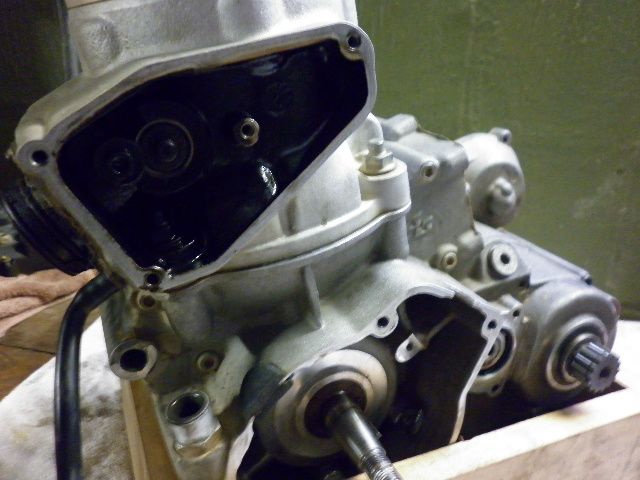

All went to plan here. No real issues. Dropped the fluids and went about removing what had to come off to get the engine out. I had planned to remove the engine complete with flywheel however it appeared to be a whole lot of work to unwire everything so just left everything connected and removed the flywheel and stator. No rust or corrosion on the flywheel at all which was fanstastic.

The 2K3 doesn't allow you to modify the timing. I will discuss this with Dave and may look at drilling this out a bit and advancing the timing just a tad.

It looks like the main seal might have been leaking slightly. There appears to be a bit of oil and dust in below the seal. The bike hadn't shown any dangerous signs of running lean but it did feel a bit flat in the top end at the end of the last ride.

Out of the bike and on the bench. I need to go and fab up a jig to hold the engine in the vice this afternoon. I think that will be the easiest way to work on it. If I'm lazy I'll just use some timber offcuts and tack up a box.

Stage 1: Engine Removal

All went to plan here. No real issues. Dropped the fluids and went about removing what had to come off to get the engine out. I had planned to remove the engine complete with flywheel however it appeared to be a whole lot of work to unwire everything so just left everything connected and removed the flywheel and stator. No rust or corrosion on the flywheel at all which was fanstastic.

The 2K3 doesn't allow you to modify the timing. I will discuss this with Dave and may look at drilling this out a bit and advancing the timing just a tad.

It looks like the main seal might have been leaking slightly. There appears to be a bit of oil and dust in below the seal. The bike hadn't shown any dangerous signs of running lean but it did feel a bit flat in the top end at the end of the last ride.

Out of the bike and on the bench. I need to go and fab up a jig to hold the engine in the vice this afternoon. I think that will be the easiest way to work on it. If I'm lazy I'll just use some timber offcuts and tack up a box.