Hello All,

I'm right now spending some time to improve the visual and performance of my EC (it's originally a 2005 250 but converted into 300 a few years ago).

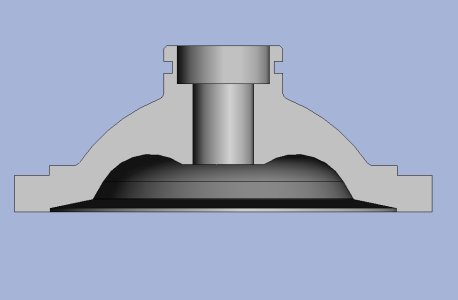

So I've reached the point of modifying the head to get a better combustion and easy jetting. I have access to a Lathe and some machining skills, so I will be doing the squish adjustment by myself. My current squish is around 2,4 mm which is quite normal for these bikes according to what I've seen in many posts here.

We have down here in Brazil 20% ethanol in all our gasolines, both in regular or premium. The premium one should be around 98 octanes (or 95 anti detonation index) and is the gas I probably will be using most of the time.

Following my doubt:

- Is it necessary to go into 1,2 mm squish to get the benefits ? Or if I adjust it for ~ 1,6 mm for instance I will see real benefits ???

I ask because I will not be able to machining the combustion chamber, only the "face" of the head, and I'm a little bit afraid that reducing to 1,2 mm will bring the compression ratio to a dangerous borderline. I'm using only one gasket of 0,5 mm on the cylinder and don't want to touch this point now.

I would appreciate all your comments !!!

I'm right now spending some time to improve the visual and performance of my EC (it's originally a 2005 250 but converted into 300 a few years ago).

So I've reached the point of modifying the head to get a better combustion and easy jetting. I have access to a Lathe and some machining skills, so I will be doing the squish adjustment by myself. My current squish is around 2,4 mm which is quite normal for these bikes according to what I've seen in many posts here.

We have down here in Brazil 20% ethanol in all our gasolines, both in regular or premium. The premium one should be around 98 octanes (or 95 anti detonation index) and is the gas I probably will be using most of the time.

Following my doubt:

- Is it necessary to go into 1,2 mm squish to get the benefits ? Or if I adjust it for ~ 1,6 mm for instance I will see real benefits ???

I ask because I will not be able to machining the combustion chamber, only the "face" of the head, and I'm a little bit afraid that reducing to 1,2 mm will bring the compression ratio to a dangerous borderline. I'm using only one gasket of 0,5 mm on the cylinder and don't want to touch this point now.

I would appreciate all your comments !!!