twowheels

Active member

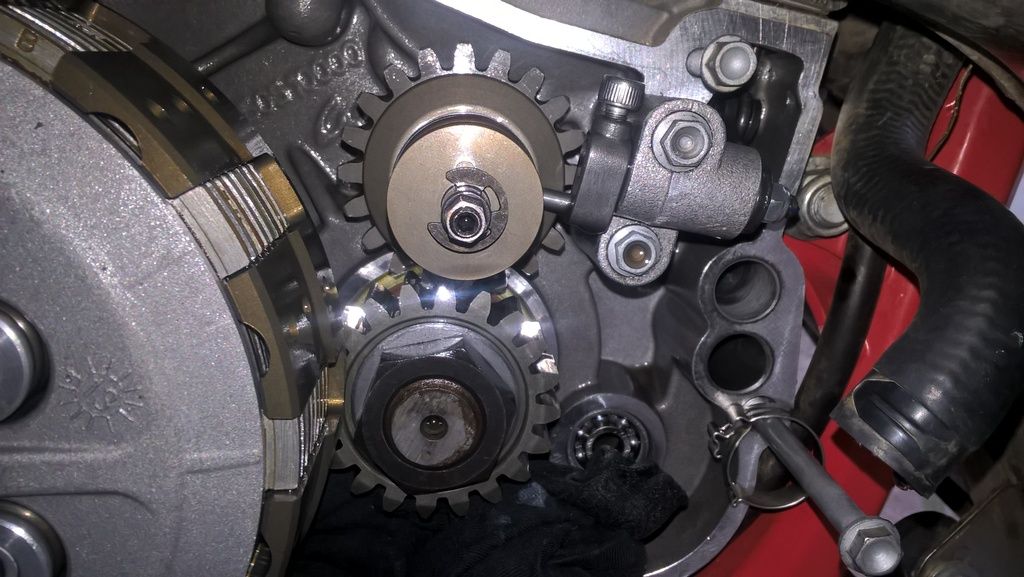

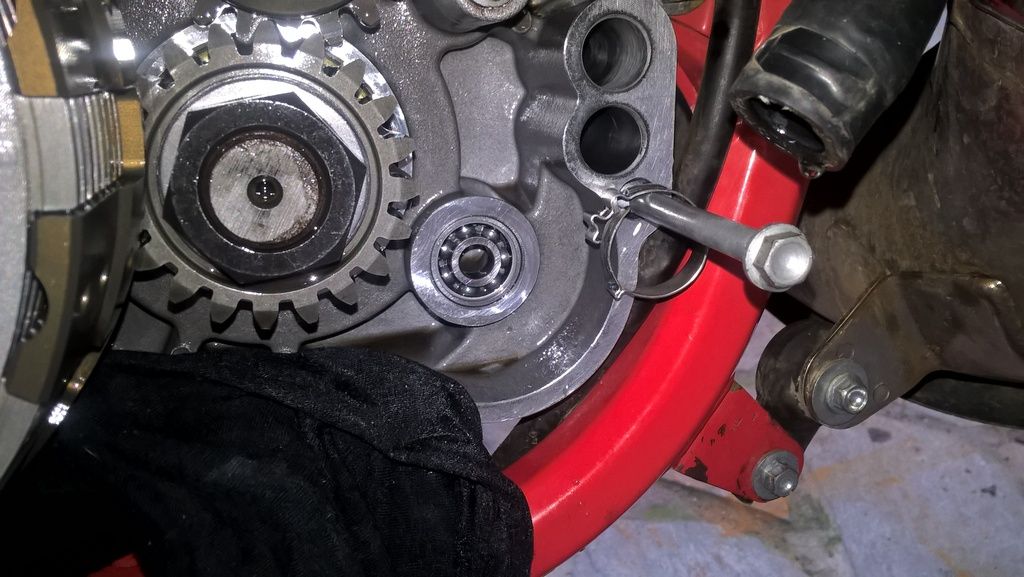

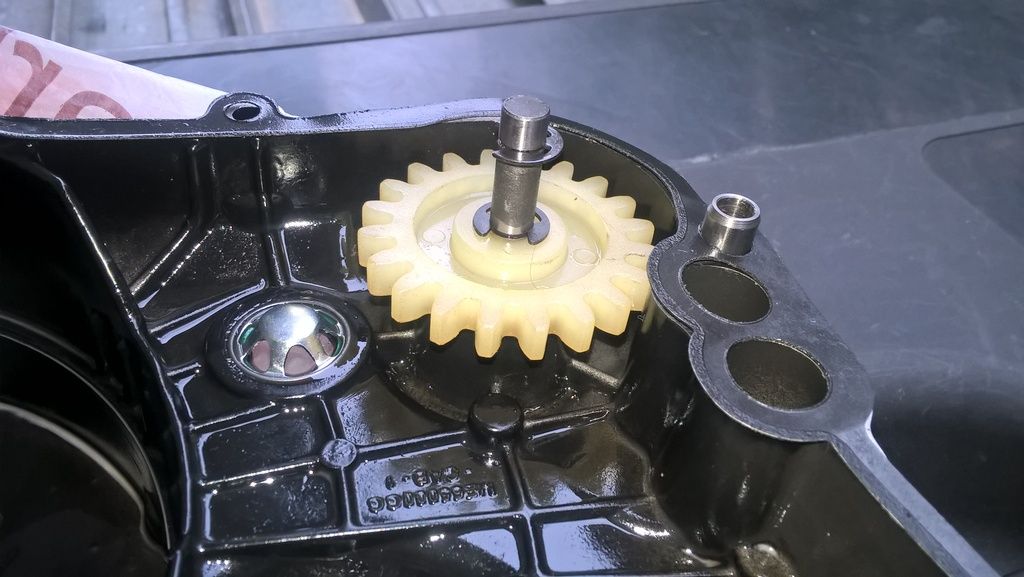

Well done - you've provided Mr. Webster a picture for his dictionary for "self-clearancing parts".

I'd clean both the cover and the impeller up a bit and provide just a little extra clearance in the chance that you tag a rock with the cover or over-snug the cover screws ... it may even feel like you've gained a few horsepower when you're done.

Last edited: