I don't think having a few of the more technically savy members here test and report on the carb is unreasonable. I'm not talking about bouncing this around the globe to everyone. A very good baseline of info could be generated as far as starting settings, installation issues (being its larger) etc. as well as the previously mentioned fuel overflow in various positions. Basically real world testing, not a dyno, and that has already been done. Many customers might expect near perfection for the price and it might pay to get any minor issues ironed out first. I would not even expect an OEM to sign onto this without having some of the factory riders wring it out. Perhaps they have we just don't know.

Ok guys. While your enthusiasm and zeal to be test pilots is most appreciable we certainly haven?t had any shortage of willing riders. Yes, the die cast carbs are where we all want to be.

I think what is not widely understood to those responding in this forum, and it's not my style to bring more to the conversation than what has been asked, however the development of any product requires necessary steps to insure validity, integrity and durability of the product. The release of the machined bodies is our way (or more accurately, my way of convincing partners and investors of the broad interest in the product) and equally important to gain actual user results/interest to move forward into the next manufacturing phase. Hard tooling for die casting costs hundreds of thousands of dollars just for one body size. You don?t even want to know what we have spent to develop this product to this point.

Anyway not your problem, however a first run of anything is not for everybody; consequently guys like Gerard who have an appreciation for new gadgets and like to be the first to toy with things are the ones who are best suited for this level of product. It is expensive but it?s worth it and Gerard has and will be rewarded for working through the small issues that he had. The only reason it took so long to get him up and running was because of us. We were at Pikes Peak setting records and winning classes.

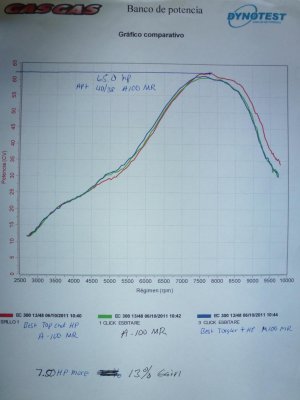

And yes this is not our first trip around the block; we have GasGas factory professional riders putting the carbs through hellish tests, enduro, MX etc. Factory racers in the US, Scott Bright, Clay Stuckey, KTM racers, Mike Fortman, Kawasaki Tim Seebold, Honda, Matt Meinart etc. Marco Belli (Zaeta, TM) in Italy, Marco even had Valentino Rossi ride his SmartCarb equipped Zaeta. Wayne Wright (Wobbly Pipes) testing in New Zealand, and the list goes on.

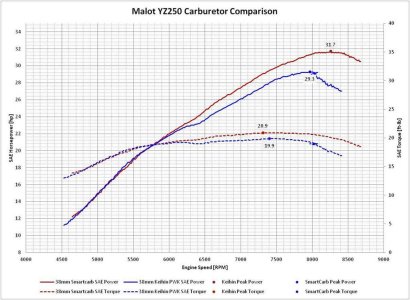

Here?s a look into my world, this morning we brought in a Alex Malott?s Razors Edge factory 2011 Yamaha YZ 250 put it on the dyno, did back to back carb comparisons. I?ll post the chart of the SmartCarb?s immediate 8% gain over a two year old race tuneup, took three minutes to put the carb on. He?ll be racing it this weekend and the next in a national MX pro series in the US.

The fit, flooding, cable issues have all been addressed and the die cast versions will have all the improvements. Men we are ready to SELL carburetors.

Respectfully,

Corey