Hello

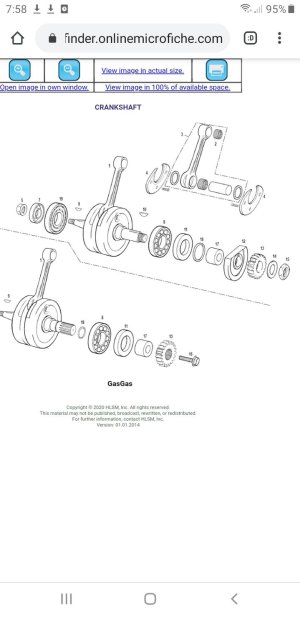

just finished doing a bottom end rebuild on my EC 300 2002 new main bearings seals and conrod installed all went together well and spins freely and selects gears well.

This engine does use the roller type bearing on one side the bearings where with c3 cleareance.

The question is there appears to be quite a lot of play side to side in the crank as in moves about in the cases but no vertical play i haven't attached anything onto the crank yet like the primary nut or flywheel would this and refitting the piston and cylinder solve this problem ?

First time doing this so didn't want to go any further in case i have done something majorly wrong ?

Any help appreciated

Matt

just finished doing a bottom end rebuild on my EC 300 2002 new main bearings seals and conrod installed all went together well and spins freely and selects gears well.

This engine does use the roller type bearing on one side the bearings where with c3 cleareance.

The question is there appears to be quite a lot of play side to side in the crank as in moves about in the cases but no vertical play i haven't attached anything onto the crank yet like the primary nut or flywheel would this and refitting the piston and cylinder solve this problem ?

First time doing this so didn't want to go any further in case i have done something majorly wrong ?

Any help appreciated

Matt