The difference in piston sizes is so slight you could probably use an A or B or C, but it's best to match it to the original B. If the piston coating is good you could re-use the piston. Measure the ring end gaps to make sure they are in spec. Without actually knowing which of your pictures is the shift fork for first gear, it's hard to advise you. I would replace that fork just to be sure since you are changing the problem gears. Extra money spent now can prevent problems later.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gas Gas ec 2006 1st gear problems

- Thread starter Munch

- Start date

The difference in piston sizes is so slight you could probably use an A or B or C, but it's best to match it to the original B. If the piston coating is good you could re-use the piston. Measure the ring end gaps to make sure they are in spec. Without actually knowing which of your pictures is the shift fork for first gear, it's hard to advise you. I would replace that fork just to be sure since you are changing the problem gears. Extra money spent now can prevent problems later.

The piston seems pretty decent but I am going to replace it for peace of mind anyway.

The shift forks are 2 different types

"MC25836009" is "shift fork 5-6" (assuming it's for 5th/6th gear?)

"MC25836008" x2 is "shift fork 1-2-3-4" which I assume is for 1st, 2nd, 3rd, 4th and they are the same so technically they are interchangeable and I could place them in 2 different places so I would need to replace them both to be sure or am I miss understanding?

I take that to mean there are two identical shift forks. Buy one new one, put that on first gear. Use the best looking old one on the other gear set.

Yeah they are both identical sorry if I explained it badly. Looking at my pics they both look the same so is it really worth buying new if they don't look worn? What sort of wear should I be looking for?

Thanks for all the help guys, I wouldn't have been able to do it without the help of the forum.

I have ordered the 2 gear cogs, piston kit and full gasket set and hopefully it will be here on Thursday and back together ready for the weekend.

Any tips for when it comes to rebuilding or things I should know?

I have ordered the 2 gear cogs, piston kit and full gasket set and hopefully it will be here on Thursday and back together ready for the weekend.

Any tips for when it comes to rebuilding or things I should know?

RockefellerGG

New member

If things don't go together easily stop and check it out. It should all go together without much force.

Jakobi

Super Moderator

As above.

If you're doing the mains heat the cases up and the bearings should fall out. When dropping new ones in, grab some dry ice and get the bearings nice and cold. Heat the cases a little and they'll fall straight in.

Same applies for the crank. Get it nice and cold and it should drop straight into the mains. Drop everything into the clutch side first, check the transmission turns through the gears properly. Lay your gasket down nicely. Then chill the end of the crank and drop the top case on. It should drop into place very easily.

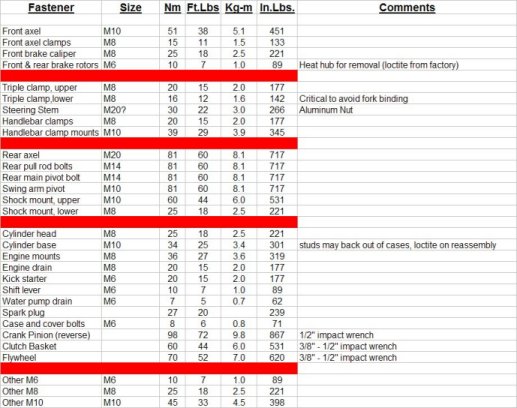

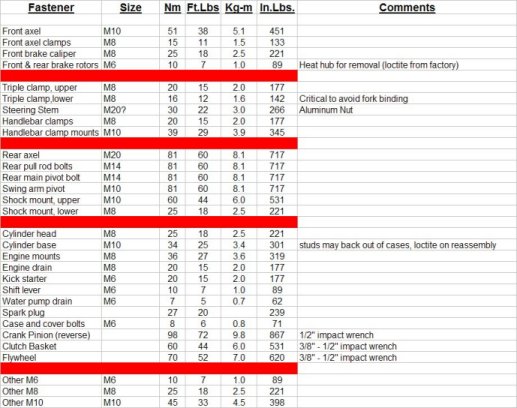

Make sure you use the torque table

The figures in the workshop manual aren't even close for some parts.

If you're doing the mains heat the cases up and the bearings should fall out. When dropping new ones in, grab some dry ice and get the bearings nice and cold. Heat the cases a little and they'll fall straight in.

Same applies for the crank. Get it nice and cold and it should drop straight into the mains. Drop everything into the clutch side first, check the transmission turns through the gears properly. Lay your gasket down nicely. Then chill the end of the crank and drop the top case on. It should drop into place very easily.

Make sure you use the torque table

The figures in the workshop manual aren't even close for some parts.

Well, . , ideally any circlips you have to remove from the gear clusters should be replaced with new. Might not need to with first.

Yeah I have bought a kit of them so I can replace anything I have taken off.

I have a few more questions!

1) Will it be ok to place the gears into the left side of the case? I was thinking of putting all the gears into place before the new ones arrive and then I can leave them inside the case and take off the gears needing to be replaced without taking everything out of the left side of the case. Does it make it more difficult starting from the left side?

2) I have a huge spacer on my reed block that I can't see on the manual, will it be taking much of my power away? Pic - http://i.imgur.com/Qkajvno.jpg

3) Is there any mod I can do while it's all apart to make the bike a bit more aggressive? I am coming from a kx 125 and the powerband in that was much more snappy, would be awesome if I could make the gas gas powerband a little more snappy.

It's too late now, but I would suggest before the tear down that you get your squish and compression ratio measurements then send off the head to get modified while you're digging into the motor.

The spacer on the reed block adds low end, if I remember correctly. It also makes removing the carb a bit more difficult. I run without, but the 300 has grunt by its very nature.

I don't have any experience inside these transmissions, so I can't help you there.

The spacer on the reed block adds low end, if I remember correctly. It also makes removing the carb a bit more difficult. I run without, but the 300 has grunt by its very nature.

I don't have any experience inside these transmissions, so I can't help you there.

It's too late now, but I would suggest before the tear down that you get your squish and compression ratio measurements then send off the head to get modified while you're digging into the motor.

The spacer on the reed block adds low end, if I remember correctly. It also makes removing the carb a bit more difficult. I run without, but the 300 has grunt by its very nature.

I don't have any experience inside these transmissions, so I can't help you there.

What does the squish do? Is it essential for me to do it?

Jacob 'Berg

Member

Yeah I have bought a kit of them so I can replace anything I have taken off.

I have a few more questions!

1) Will it be ok to place the gears into the left side of the case? I was thinking of putting all the gears into place before the new ones arrive and then I can leave them inside the case and take off the gears needing to be replaced without taking everything out of the left side of the case. Does it make it more difficult starting from the left side?

You could place the gear sets in the left side case half until you get each gear set assembled with the new parts, but you will want the gears in the right side case for re-assembly of the case halves.

You could place the gear sets in the left side case half until you get each gear set assembled with the new parts, but you will want the gears in the right side case for re-assembly of the case halves.

Thanks, I will just leave it until the parts arrive and assemble it in the right side then.

Similar threads

- Replies

- 12

- Views

- 2K

- Replies

- 9

- Views

- 2K

- Replies

- 5

- Views

- 4K