Hello, gentlemen.. New to this site, but have been a lurker from time to time. I spend most of my time on Ktmtalk, working with members to tweak their heads and bore carbs to get the results they are wanting. I recently began doing GG heads, and was glad to be able to get on this site and read that several riders on here seem very knowledgeable on the subject... Since I don't own a GG, and my buddy sold his, I no longer have a test mule... One subject I would like to test further, is the flat squish band theory... That technology is 40+ years old, and isn't popular with manufacturers any longer. Several schools of thought offer pro's and cons on having parallel squish versus angled squish... Maybe some of you guys who have purchased modded heads can shed some light on the subject..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head mods

- Thread starter Ls1jy

- Start date

Jakobi

Super Moderator

The Gassers use a domed piston, and I believe RB mods the heads to match the angle of the piston. Someone else will be able to provide more info on this for sure.

In saying that I went with an after market S3 head with inserts and had the high high compression insert modified to meet my needs when matched with a hand ported S3 Race cylinder.

The finished product... Left the squish band and gasket surface alone, just machined extra volume into the dome... Kept the standard roof height, just made it flatter and wider... Old head vol was 17.5cc new head vol 21cc, when the cyl is dropped by 0.8mm it'll give 1.25mm squish, 2 degree difference between the piston and squish band and approx 14:1 CR.

In saying that I went with an after market S3 head with inserts and had the high high compression insert modified to meet my needs when matched with a hand ported S3 Race cylinder.

The finished product... Left the squish band and gasket surface alone, just machined extra volume into the dome... Kept the standard roof height, just made it flatter and wider... Old head vol was 17.5cc new head vol 21cc, when the cyl is dropped by 0.8mm it'll give 1.25mm squish, 2 degree difference between the piston and squish band and approx 14:1 CR.

Good info, jakobi. That S3 is a fine looking head.

Another interesting tidbit I was wondering about, the heads on the late model GG bikes either have some tough alloy in them, or they are hard anodized. When I cut thru the surface, they are more resistant to material removal than the heads on the KTMs.

Another interesting tidbit I was wondering about, the heads on the late model GG bikes either have some tough alloy in them, or they are hard anodized. When I cut thru the surface, they are more resistant to material removal than the heads on the KTMs.

Well, just a very good report back from my suspension guy Richard out in Oklahoma... I modded his '12 300 head, and worked with him to closely match his piston angle... He also plugged the vent hole in cylinder above exhaust port, and added a bigger PV cover. He called with a ride report, and said it ran like a 'raped ape' as he put it... Lots more low and midrange, and he was able to go back to more traditional jetting... He also said it idled very smoothly, without hiccups, and rpm changes...

djroggen

New member

Would the squish be the same on every gasgas of the same model and year, or would it vary from bike to bike? Would all 2011 ec 250's be set the same from the factory?

No, depending on the base gasket and tolerances, each bike is nearly the same but all are slightly different in regards to squish.

Got a few more calls to do some more head mods... Seems like the 300's for '12 model don't run nearly as well as some of the older 300's... and I am being told that stock, they are a pain to keep jetted, and smooth idle... The first guy I helped a few weeks ago said his jetting became much easier to tweak, and his weird idling issue went away with the mod. he also said he epoxied up the vent hole in his cylinder... after I modded his head, its a bear to kick over now, and five or six times is wearing out his leg...maybe not a great thing to do??

twowheels

Active member

he also said he epoxied up the vent hole in his cylinder... after I modded his head, its a bear to kick over now, and five or six times is wearing out his leg...maybe not a great thing to do??

That little guy is there for a reason

Diggs345

Gold Level Site Supporter

The Gassers use a domed piston, and I believe RB mods the heads to match the angle of the piston. Someone else will be able to provide more info on this for sure.

In saying that I went with an after market S3 head with inserts and had the high high compression insert modified to meet my needs when matched with a hand ported S3 Race cylinder.

The finished product... Left the squish band and gasket surface alone, just machined extra volume into the dome... Kept the standard roof height, just made it flatter and wider... Old head vol was 17.5cc new head vol 21cc, when the cyl is dropped by 0.8mm it'll give 1.25mm squish, 2 degree difference between the piston and squish band and approx 14:1 CR.

Was that done on a milling machine ?

Diggs345

Gold Level Site Supporter

Diggs,

Have you had your head done, and hows the smart carb,

V-tec

Yes i had my head done , not exactly what i wanted but it definatly ran better.

If you look in the reviews section i put a small thread in thier.

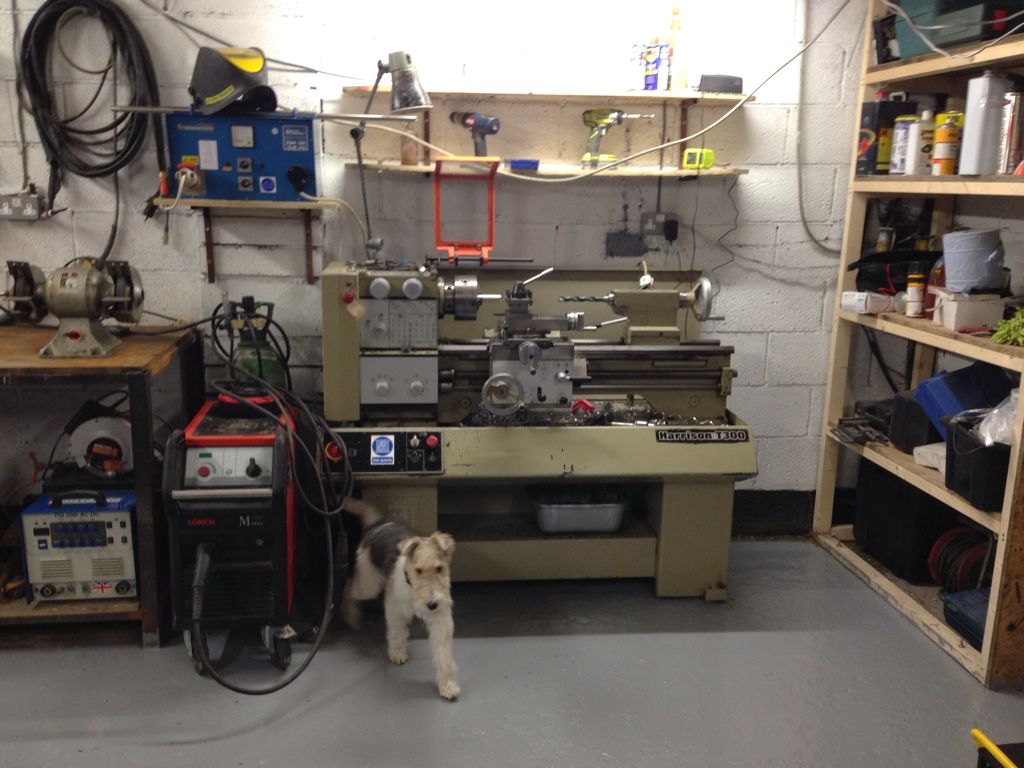

I will have a lathe next week so ill be looking for some old heads to practice on

andoman

New member

ASII Part of Problem

In addition to squish being all over the map, part of the issue is likely with the ASII carb on the newer bikes (since '10?). It seems to be very sensitive to float height variation.

Also, the factory jetting is completely out the window. Not anywhere close. It all makes for some frustrating initial setup.

Seems like the 300's for '12 model don't run nearly as well as some of the older 300's... and I am being told that stock, they are a pain to keep jetted, and smooth idle...

In addition to squish being all over the map, part of the issue is likely with the ASII carb on the newer bikes (since '10?). It seems to be very sensitive to float height variation.

Also, the factory jetting is completely out the window. Not anywhere close. It all makes for some frustrating initial setup.

Diggs345

Gold Level Site Supporter

Looks like a cnc too , im guessing that would be hard to do on a manual latheYeah Diggs!

Also agree with everything Ando has just said about the AS2 carbs. Completely different beasts from the AS1 but the factory still feels the need to ship with the same stock jetting that is no where even close to right.

Last edited:

byost

Gold Level Site Supporter

Diggs, have you ever used a Tool Post mounted Radius Cutter? We have one in the shop I work in. It mounts to the Cross Slide and uses a single point Lathe tool and you"swing" the radius by hand. The radius is adjustable and the depth is changed by moving the carriage.I think this would be the hot setup for a manual Lathe.

Brian.

P.S. nice guard dog!

Brian.

P.S. nice guard dog!

Similar threads

- Replies

- 4

- Views

- 3K

- Replies

- 21

- Views

- 20K

- Replies

- 59

- Views

- 21K