This may be already answered by wise Jakobi, but none the less, thanks in advance for reading and commenting.

I would like to know the proper way to cut a chain. I see "cutting" referenced here many times, and always like and excuse to buy a new tool, but a chain breaker and press runs around $110 (DID).

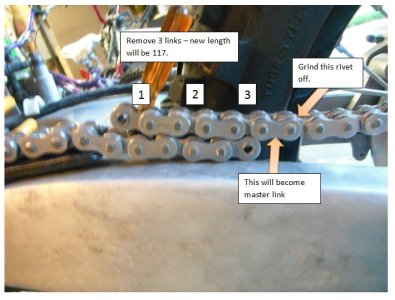

I am running an ironman 13 front, JT 52 rear, and an RK 520 EXW 120 link chain. It looks like I need to remove 3 links to be in the middle of the adjustment range. What is the proper method?

1. Buy the tool, press it out. (Need to to wait till Tuesday if so)

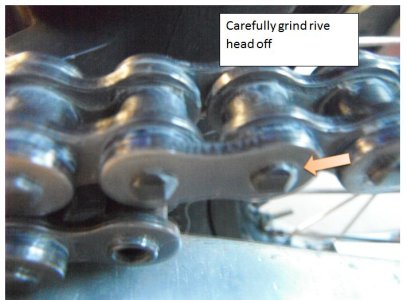

2. Use a grinder to carefully remove the pin and press it out. (I already have air and electric grinders, and feel I can carefully do this.)

The chain instructions also reference using a press tool to install the master. They say not to use vise grips (gee what about duct tape). I have read where others have left out one side of the O-rings because it is too hard to properly install the clip.

I am ok to wait, but sure would like to run this thing up and down the block tonight, annoy some neighbors and kill some skeeters!

Attached are pics of the chain and my thoughts on where to cut and grind, and a shot of the new rear wheel set! Front is on next!

I would like to know the proper way to cut a chain. I see "cutting" referenced here many times, and always like and excuse to buy a new tool, but a chain breaker and press runs around $110 (DID).

I am running an ironman 13 front, JT 52 rear, and an RK 520 EXW 120 link chain. It looks like I need to remove 3 links to be in the middle of the adjustment range. What is the proper method?

1. Buy the tool, press it out. (Need to to wait till Tuesday if so)

2. Use a grinder to carefully remove the pin and press it out. (I already have air and electric grinders, and feel I can carefully do this.)

The chain instructions also reference using a press tool to install the master. They say not to use vise grips (gee what about duct tape). I have read where others have left out one side of the O-rings because it is too hard to properly install the clip.

I am ok to wait, but sure would like to run this thing up and down the block tonight, annoy some neighbors and kill some skeeters!

Attached are pics of the chain and my thoughts on where to cut and grind, and a shot of the new rear wheel set! Front is on next!