You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

23 ounce flywheel weights

- Thread starter Mark Berg - CPD

- Start date

Leo

New member

Guys, I have done the hard work already and done my flywheel. If someone want one, just use my drawing to machine one wherever you are.

http://youtu.be/16d-ewfc8lU

http://youtu.be/16d-ewfc8lU

YellowGasser

New member

It's hard to read my flywheel part #'s It's FP8184 same number as an '04 EC250

Jim Cook

Platinum Level Site Supporter

Guys, I have done the hard work already and done my flywheel. If someone want one, just use my drawing to machine one wherever you are.

http://youtu.be/16d-ewfc8lU

Leo,

Thank you for doing all that work and posting a video on youtube. It looks professional. Good Job!

I see the difference between your's and the commercially available aftermarket FWW is that they have the nut milled onto the outside, in addition to the extra thickness to give it the extra weight..

Yellowgasser,

You do indeed have the originally equipped ignition on your '97 EC250. It has had the external lighting set-up removed and a newer style nut retaining the flywheel. (I love seeing the counterbalancer in place.)

"side note: you need to get control of the corrosion in your ignition area. If it rusts and pits the surface of your crank, you will start damaging the left crank seal and cause a very lean condition."

If you were to make a FWW using Leo's drawings, you would have to modify the measurements to keep the same outside diameter as your flywheel (to keep from interfering with the pick-up coil), and make sure that the rivets in the flywheel cleared the back side of the weight.

Any of the commercially available "spin on" FWWs made for the smaller ignition used by GasGas in the MC, XC, SE, and DE models will work for you, but will not normally weigh anywhere near 23oz.

Keep in mind that the OEM "add-on" weight was included to "excite" the additional lighting windings bolted to the inside of your metal ignition cover. It did not "spin on" as Leo's does, but rather was retained by a longer flywheel nut.

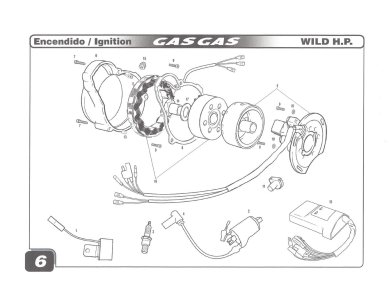

I scanned a page from the Wild HP 300 quad's parts book. The quad's engine is counterbalanced with the same system as your '97, and uses the same ignition set-up as your bike came with. I am trying to attach a copy of the scan to this post.

Maybe we will end up at Brock Creek at the same time this fall/winter. I'd enjoy riding with you, if you don't mind waiting on me.

Good Riding!

Attachments

desertgasser300

Banned

Thanks for posting that schematic, that saves me today from pulling apart my 97' and 12' to take pics and show the differences.

Yellowgasser, if you can find that piece on ebay or a part out, it will be well worth it. You will have a new love for that motor.

Yellowgasser, if you can find that piece on ebay or a part out, it will be well worth it. You will have a new love for that motor.

YellowGasser

New member

Thanks for the info Jim. I found out the hard way the ignition wasn't sealed. She left me stranded in a water hole this summer. I have Ken Oconor Racing boring the wife's Yamaha warrior cylinder. Hopefully as soon as I give it a couple heat cycles were heading to Chadwick atv area. Been wanting to go all year. It will be the 1st time for me, her and the 2 boys.

Dessertgasser300, I'm sure I will love it with the extra weight. Maybe my 11yr old boy will try to ride it. Over the weekend he decided it was time to try out my old XR200R. His feet barely go past the footpegs lol.

Dessertgasser300, I'm sure I will love it with the extra weight. Maybe my 11yr old boy will try to ride it. Over the weekend he decided it was time to try out my old XR200R. His feet barely go past the footpegs lol.

YellowGasser

New member

farmerj

Platinum Level Site Supporter

What size is that nut?

I didn't have a metric socket large enough, used 1-3/16, but the socket "bottomed out" on the fww because the socket wall was too thick to fit inside the machined area.

I wouldn't be surprised if the nut was "bottomed out" also, and there is 1/16" play in the fww. Has anyone had that problem?

Thanks,

Jeff

'05 DE 300

-------------------------

I didn't have a metric socket large enough, used 1-3/16, but the socket "bottomed out" on the fww because the socket wall was too thick to fit inside the machined area.

I wouldn't be surprised if the nut was "bottomed out" also, and there is 1/16" play in the fww. Has anyone had that problem?

Thanks,

Jeff

'05 DE 300

-------------------------

Had flywheel cover off last night getting my head ready to send to RB Designs.

Took some pics of my S3 Wt installed.

As mentioned above before, the installation is very easy if you have an impact wrench. Zip off the OEM nut, pull the OEM flywheel. Install the new S3 wt. Add a dab of blue loctite to the included S3 nut. Zip it back on with impact wrench. Put on the OEM cover (I had the aftermarket GG aluminum cover and it would not fit due to the thicker S3 wt....solution would be to have it machined out inside the cover but have not taken the time to do that). I did have to add a 2nd gasket just to make clearance to the OEM cover. I know others above that did not though.

That's it!!

Sent from my iPhone using Tapatalk

Last edited:

motopsycho87

New member

Love my weight! Bike still spins up where ever I want it to, it just doesn't spin when I don't want it to!

farmerj

Platinum Level Site Supporter

S3 fww review:

I just came off the mountain today, great riding - and I love that flywheel weight! It is certainly a rider preference - those who like a "fast hit" probably wouldn't like it - but this is what I have trying to make my bike do for a couple of years now.

It's like a sewing machine! Get on a 2nd gear singletrack hill, put it in 3rd (or 4th!,) and just motor up. Grab a handful of throttle and you just get more power and forward motion, not wheelspin that throws you off-line. Nasty roots or rock ledge? No problem, no stall. It's really not that far off of the feel of my txt321 trials bike, but with a lot more on top!

I have re-jetted, added a V-Force 2 reed cage, reed spacer, larger powervalve cover, RB'd the carb and head, and more recently went to a 2K-3 ignition (it was a "DE" with 2K-2 and 14oz. fww before.) Adding the S3 weight did the trick for me!

If you're one of those guys who likes to ride a gear high and "lug it," I think you'd like this product.

I just came off the mountain today, great riding - and I love that flywheel weight! It is certainly a rider preference - those who like a "fast hit" probably wouldn't like it - but this is what I have trying to make my bike do for a couple of years now.

It's like a sewing machine! Get on a 2nd gear singletrack hill, put it in 3rd (or 4th!,) and just motor up. Grab a handful of throttle and you just get more power and forward motion, not wheelspin that throws you off-line. Nasty roots or rock ledge? No problem, no stall. It's really not that far off of the feel of my txt321 trials bike, but with a lot more on top!

I have re-jetted, added a V-Force 2 reed cage, reed spacer, larger powervalve cover, RB'd the carb and head, and more recently went to a 2K-3 ignition (it was a "DE" with 2K-2 and 14oz. fww before.) Adding the S3 weight did the trick for me!

If you're one of those guys who likes to ride a gear high and "lug it," I think you'd like this product.

motopsycho87

New member

I wouldn't even say riding in a higher gear is the best benefit!

To me the best benefit is stopping the bike from losing traction, when on a steep dusty hill climb it is easy for the rear wheel to spin up and lose grip, instantly you shut the throttle or feather the clutch to find grip, but with the weight it just simply doesn't happen, it just pulls, even when revving the tits off it in first!!!

To me the best benefit is stopping the bike from losing traction, when on a steep dusty hill climb it is easy for the rear wheel to spin up and lose grip, instantly you shut the throttle or feather the clutch to find grip, but with the weight it just simply doesn't happen, it just pulls, even when revving the tits off it in first!!!

motopsycho87

New member

Following on from my last post, I've taken it off to try the local mx track tomorrow. I've done a few enduros on it, and to be honest it's quite tiring, wheel spin allows you to fall into ruts and isn't transferred to the rider as a jolt. Next enduros I do isn't for another month but I like to do trail riding close to home so I'll let you know how I get on. I think it might be a case of its better for newer riders, but those who need to slide to find the track and constantly need to blip the throttle, a weight this big seems to be quite tiring!

Tomac

Gold Level Site Supporter

This FWW sounds perfect for me. Long story short my last bike was a 08 WR450 (sold in 2010), then I had a test ride on a 2016 Beta 250 & 300 last year & that's convinced me to get a 2T next.

Two weeks ago I bought a 2007 GasGas EC 250, I haven't had a chance to ride it yet but Im hoping (wishful thinking) that it will be like the Beta, I was very impressed with the Beta because they climbed like a 4t 450. So from what I can gather from the comments in this thread this S3 FWW will make it tractor through mud & hill climbs.

Two weeks ago I bought a 2007 GasGas EC 250, I haven't had a chance to ride it yet but Im hoping (wishful thinking) that it will be like the Beta, I was very impressed with the Beta because they climbed like a 4t 450. So from what I can gather from the comments in this thread this S3 FWW will make it tractor through mud & hill climbs.

motopsycho87

New member

Definitely not having it on suited the terrain today, sandy dry motocross track, gonna keep it off for the next enduros and see how I get on. Think there are benefits both ways, but when speed it key, run without!

They are in Canada.

http://rypusa.com/s3-spacer-flywheel-weight-gg/

It's only 24 bucks?! I may have to give it a try...

So, the 23 oz fww on a 2k2 would be a similar MOI than if I had a 2k3 ignition and a 10 oz or so?

It's only 24 bucks?! I may have to give it a try...

So, the 23 oz fww on a 2k2 would be a similar MOI than if I had a 2k3 ignition and a 10 oz or so?

Similar threads

- Replies

- 2

- Views

- 5K

- Replies

- 12

- Views

- 7K