You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GG 2011 300, big ass flat spot at 7k 57mpg

- Thread starter rgranger

- Start date

Jakobi

Super Moderator

it just won't pull anymore, no mis, no power loss like fuel, it just won't pull past 7grand in 5 or 6th. I think that I have the 172 jet in it, filter is clean. plug looked good, real good, tried a brand new one same results. No pull after 7000rpm.

Rob

Go up to a 178 main and go for a run. Its a quick and easy way to tell. Generally a lean main will just fall flat on its face and stop making power. A fat main will burble and carry on.

Otherwise could be ignition related but try the simple things first. Flick the dual mode switch? Has it ever revved past 7G or is this something new? How many hours on engine? Powervalve functioning?

Jakobi

Super Moderator

The needle is most effective around 1/4 throttle and carries past half, tapering down to 3/4. From here its mostly main jet. If you are happy with the delivery up to this point I wouldn't go messing with the needle. Try out a few mains. JD kits usually require a few sizes larger than you would normally run due to the third taper leaning off again. Being a 300 you'll b lucky to see more than 9500-10000rpm out of them, but 7G is a bit too low. Up the main

stainlesscycle

Site Sponsor

you should be able to move pv easily by hand, but you will need to disconnect pv actuator rod, or you'll dislodge the balls.

motogroove

New member

you should be able to move pv easily by hand, but you will need to disconnect pv actuator rod, or you'll dislodge the balls.

OMG!!! Maybe I dislodged my balls!!!

-Dean

Full set of gaskets x2 coming for me. It only took me a month to order them.

stainlesscycle

Site Sponsor

i definitely dislodged my balls sunday when i broke my frame and subframe on a hillclimbOMG!!! Maybe I dislodged my balls!!!

gotta tear it all apart, and off to the welder it goes again.

rgranger

Gold Level Site Supporter

Well, this took a sad, sad turn

Say, when I disconnect the actuator rod, do I just undo the little nut?

Stupid question, how does the little nut on the rod come off, it just spins?

Do I remove the triangle first?

just sitting there, looks like I have almost 1/4 inch of free play in the rod. Is this the slack that they talk about in other threads that needs to be removed?

Thanks,

rob

Say, when I disconnect the actuator rod, do I just undo the little nut?

Stupid question, how does the little nut on the rod come off, it just spins?

Do I remove the triangle first?

just sitting there, looks like I have almost 1/4 inch of free play in the rod. Is this the slack that they talk about in other threads that needs to be removed?

Thanks,

rob

noobi

New member

Well, this took a sad, sad turn

Say, when I disconnect the actuator rod, do I just undo the little nut?

Stupid question, how does the little nut on the rod come off, it just spins?

Do I remove the triangle first?

just sitting there, looks like I have almost 1/4 inch of free play in the rod. Is this the slack that they talk about in other threads that needs to be removed?

Thanks,

rob

You should just remove the tiny nut thats there, yes.

It is threaded onto a stud that is supposed to be tacked to that plate, but its not uncommon for it to break the weld before the nut comes off, in which case you will need to remove that plate in order to grab the stud to get the nut off. When this happened on one of my bikes, we tapped a thread where the stud passes through, locktited a cap screw in, and use a nylock nut so it doesnt need to be done up so damn tight

Yes, thats the free play that everyone talks about, the whole mechanism just kind of floats around before being under any tension from the pv rod, the plate should rest on the bolt.

rgranger

Gold Level Site Supporter

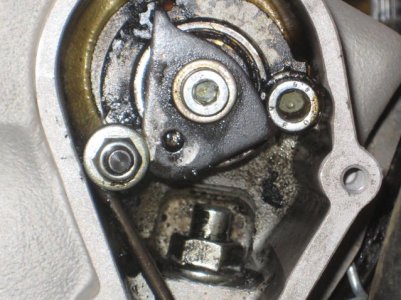

I opened another thread with a picture, would you mind taking a look and seeing if this is what you mean by "broken off" - LOL.

http://www.gasgasrider.org/forum/showthread.php?p=66354#post66354

Well, i guess I could upload a picture here...

http://www.gasgasrider.org/forum/showthread.php?p=66354#post66354

Well, i guess I could upload a picture here...

Attachments

rgranger

Gold Level Site Supporter

See if I have this right, you tapped the hold, ran a screw through from the back side with loctite and then put a small nylock on the outside where it should be.... that translate right?

You should just remove the tiny nut thats there, yes.

It is threaded onto a stud that is supposed to be tacked to that plate, but its not uncommon for it to break the weld before the nut comes off, in which case you will need to remove that plate in order to grab the stud to get the nut off. When this happened on one of my bikes, we tapped a thread where the stud passes through, locktited a cap screw in, and use a nylock nut so it doesnt need to be done up so damn tight

Yes, thats the free play that everyone talks about, the whole mechanism just kind of floats around before being under any tension from the pv rod, the plate should rest on the bolt.

noobi

New member

See if I have this right, you tapped the hole, ran a screw through from the back side with loctite and then put a small nylock on the outside where it should be.... that translate right?

Yea, haha. Tapped the hole so the cap screw we put in did the same thing as the stud.

However, be careful with your taps because the remaining tack weld snapped a few of our taps

The picture looks like its not even attached to the plate?

Did the stud snap off and its now just floating there held onto the rod with that nut?

EDIT, im pretty sure the stud has snapped but a portion is still tacked to the plate, because you cant see the bearing through the hole

rgranger

Gold Level Site Supporter

Yeah, I think so.... looks like it has been doing that for a while by the wear patterns. I mostly ride tight trail and rarely get up above 7k, buddy was riding down the road and noticed it. I have not been on the bike in 4 months due to busted shoulder. Rode it 3 times before getting cut, so I really don't know what is right. I am guessing that it may stop spooging as much and run better with a functional powervalve?

rgranger

Gold Level Site Supporter

so I do need to pull the side off and go digging for little bits of stud? Sorry, mis-read, maybe all the bits are there. need to drill the hole out and put a screw in or re-weld.

Yea, haha. Tapped the hole so the cap screw we put in did the same thing as the stud.

However, be careful with your taps because the remaining tack weld snapped a few of our taps

The picture looks like its not even attached to the plate?

Did the stud snap off and its now just floating there held onto the rod with that nut?

EDIT, im pretty sure the stud has snapped but a portion is still tacked to the plate, because you cant see the bearing through the hole

noobi

New member

A powervalve that doesnt open would definitely cause a big ass flat spot.

To remove the plate you just undo the capscrew thats holding it on. I would drill out the remaining part of the stud, find a bolt thats the same length as the stud, tap a thread through the hole, loctite the bolt in, the right way round. Then put everything back together.

That probably doesnt make much sense, but I think you understand what im trying to say.

We used the tap and loctite method because we dont have a welder at home, by all means, a new bolt that was properly welded on would probably be better. I wouldnt reuse the stud, its much easier just to put a new bolt there imo.

I doubt the stud would have shattered into little pieces, I would just drain the tranny oil. If you wanted to remove the freeplay in the PV system, you would be removing that side cover anyway.

To remove the plate you just undo the capscrew thats holding it on. I would drill out the remaining part of the stud, find a bolt thats the same length as the stud, tap a thread through the hole, loctite the bolt in, the right way round. Then put everything back together.

That probably doesnt make much sense, but I think you understand what im trying to say.

We used the tap and loctite method because we dont have a welder at home, by all means, a new bolt that was properly welded on would probably be better. I wouldnt reuse the stud, its much easier just to put a new bolt there imo.

I doubt the stud would have shattered into little pieces, I would just drain the tranny oil. If you wanted to remove the freeplay in the PV system, you would be removing that side cover anyway.

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 0

- Views

- 4K

- Replies

- 6

- Views

- 4K

- Replies

- 7

- Views

- 6K