stainlesscycle

Site Sponsor

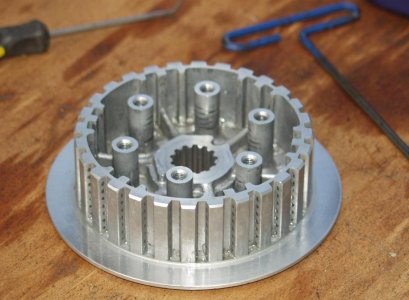

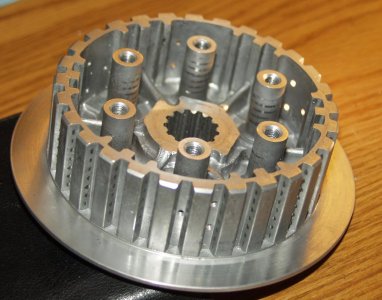

when i drilled holes (18 total holes in my hub now) it fixed sticky plates/kick start in gear issues. i never had a squawky clutch - neither of my baskets have webbing.... the holes just let more fluid pass to keep plates stiction at a minimum. i think the basket is possibly what causes squawking... does anyone have squawky clutch and no web basket? my clutch has never squawked with amsoil 0w-40 or maxima xtl or rotella t for that matter. i like the amsoil because it's got the lowest friction coefficient.