Jakobi

Super Moderator

This post is starting to compete with Brent's posts as the reality show enthrall of the year, hurry up and ride it...... Actually don't hurry, the suspense is just awesome!

Should I start blending the suspension talk into this thread too? I think I'm going to have to run the Ohlins 888 for at least a test run once I get the engine stitched back up and broken in.

Picked up some new bearings for the powervalve assembly and also gave the powervalve a bit of a clean up and polish. Will be spending the time to ensure the exhaust spigot matches the port 100% as well. Have to test the preload on the powervalve yet too, and if required will pull the RHS engine cover and adjust as neccessary.

Dave has also been kind enough to machine up 3 x 8mm spacers for the LHS powervalve cover which he'll send up at a later date. I'll be able to experiment to determine which provides the best bottom end.

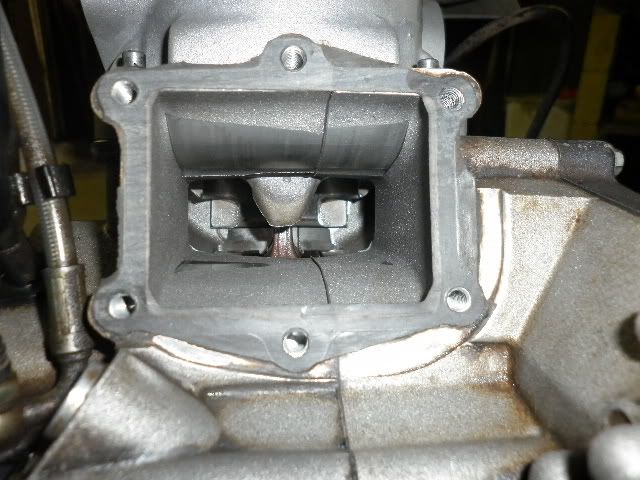

And.. I still need to pull the carb and check the reeds over. They were replaced not that long ago so expected to be in good working condition. While in there I'll remove the spacer which is meant to boost snap and response on the bottom. She'll be like a new bike!