Vindicator

Member

To prevent some of the misfortunes related here I decided to check "Carmen's"  watter pump.

watter pump.

Started by draining the antifreeze

Sorry about the funnel, it goes back to my orange fever days

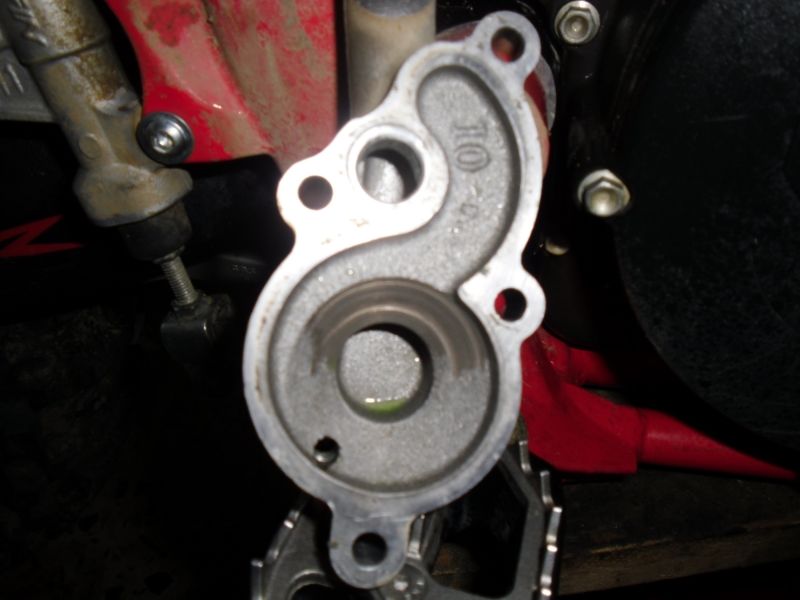

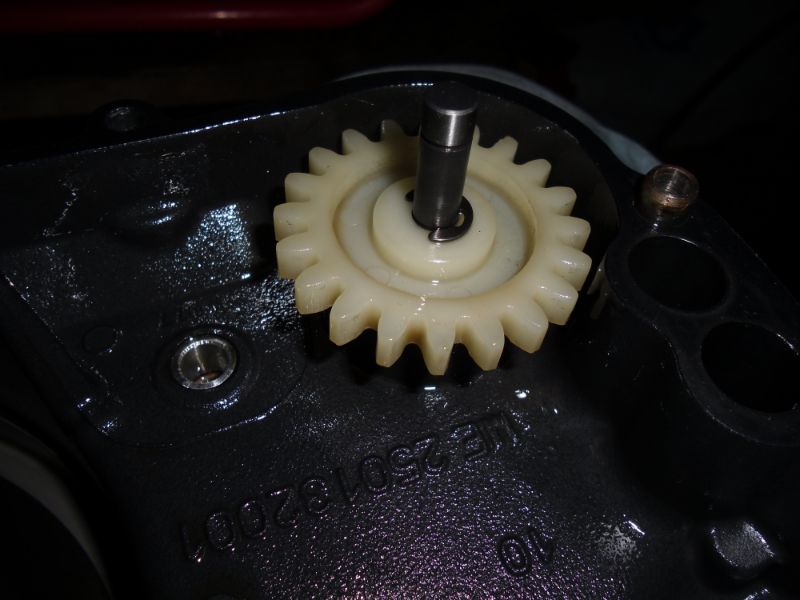

Removed the watter pump cover and found this:

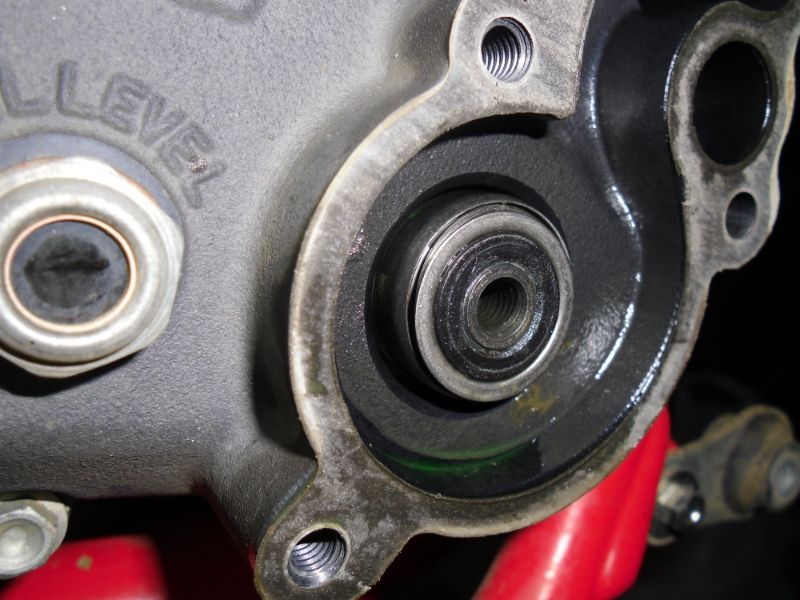

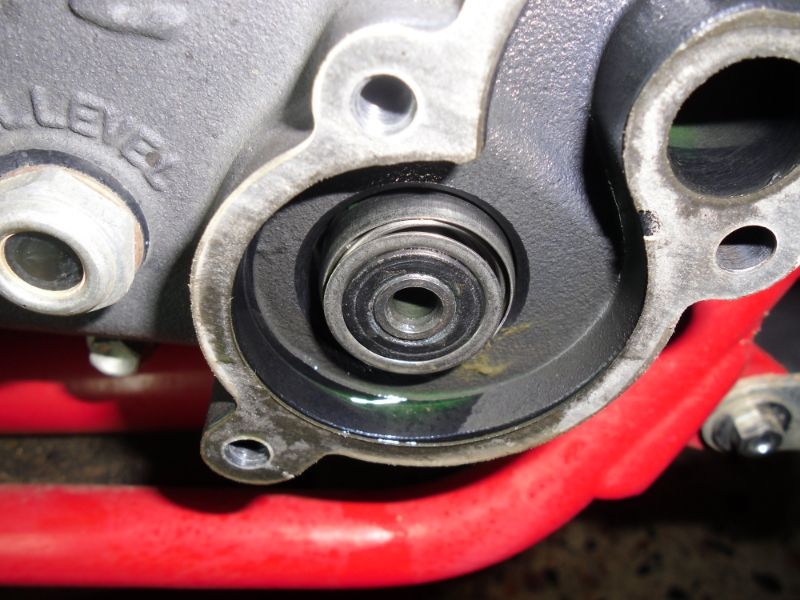

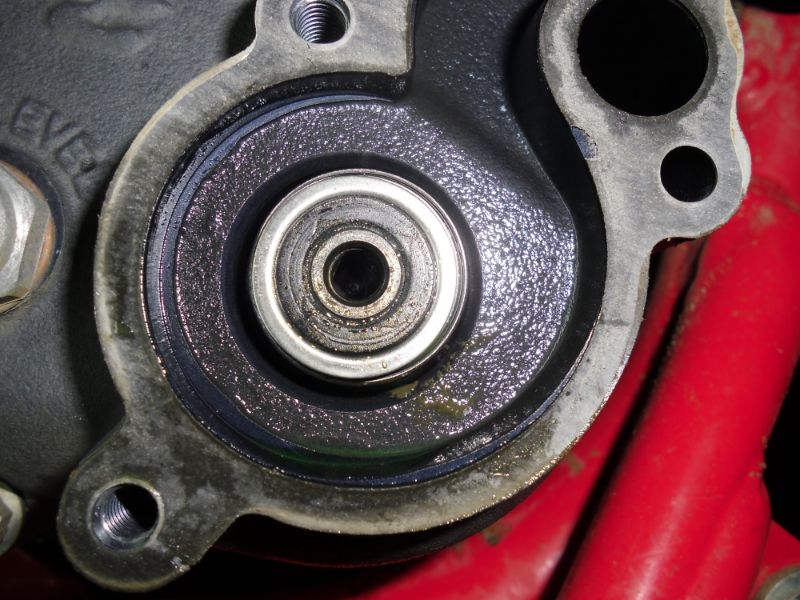

It's clear that it's been rubbing against cover

Started by draining the antifreeze

Sorry about the funnel, it goes back to my orange fever days

Removed the watter pump cover and found this:

It's clear that it's been rubbing against cover