ok, i figured i'd put all the data in one place.

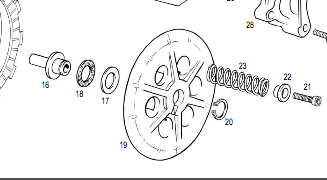

cr250r clutch pack conversion:

stock gg friction plates: 2.85mm (some are 2.9mm)

stock gg steel plates 1.5mm

use honda cr250r

1994-2007

cr250r friction plates 3mm

cr250r steel plates 1.5mm

cr250r plates, clutch stack height = 30mm

gg plates, clutch stack height = 28.95mm

no mods need to be done to use cr250r steel plates.

to use cr250r clutch friction plates:

you can mill the inner clutch hub spacer (gg #ME25632011). You want to mill the one between the hub and the basket (not the one behind the basket) to between 1.80mm and 1.95mm (stock is 2.8mm - 3.00mm depending on year?) thick - mine is 2mm - and it drags slightly. i fixed this with 2 stock gg friction plate in the mix. you can adjust the clutch drag by mixing and matching stock and cr250 frictions. with bike running or not, hot or cold, i can put bike in gear, pull clutch and push bike around....with stock clutch, it would drag badly, and would not allow this. keep in mind there's a fine line between dragging and slipping. if your stack height gets too thin, it will slip. but when it's just right it's perfect...

if you don't want to mill the spacer, i believe suzuki part #08211-22423 is already 2mm thick (confirmed 2mm thick by bitoman) kawasaki also has a clutch spacer about 2mm thick. do some research and you will find it.

other options:

get thinner steels from rekluse. this is more expensive than using a complete cr250r clutch pack.

if you do convert to cr250r clutch, be nice and make sure you paint marker 'cr250r' inside the clutch cover so the next guy who owns your bike doesn't end up scratching his head when his brand new gg clutch pack won't work...

dragging clutch solutions:

lighter oil - i use amsoil 0w-40 and maxima mtl xl (75w) - both work nicely. i have been told fully synthetic atf is even more slippery, and may help dragging..but atf has no shock modifiers as far as i know...

lower your stack height - if you clutch stack is 29mm or more, it will drag - not enough free space when clutch is pulled. you can decrease your stack height by using thinner steels - rekluse sells them - it only takes .1 - .2mm less or so to go from dragging to slipping.... try one 1.4mm steel first and see if it works..

check your hub and basket for wear on the fingers/grooves. if there's wear you can draw file them smooth - this only works once or twice - after that too much material is gone and the clutch will chatter/break plates

check your steel plates - any warpage can cause drag.

Squealing/Chirping clutch

as shown elsewhere, there are at least 3-4 different baskets -

http://www.gasgasrider.org/forum/showthread.php?t=8486

i found on my inner hub, that there were only 6 holes drilled in it. not 18 like the one pictured in link above. i drilled 12 additional holes, and my clutch is significantly smoother/easier to slip/and makes absolutely no noise.

other stuff:

make sure your cush drive inserts are not worn out, and no rivets are missing. there should be no play between the primary gear and the basket... i drilled my rivets out and tapped in new screws instead of rivets. i used grade 8 5x14 button head sockets, that i screwed in from the backside of the basket.. and at least blue loctite them....

if you are breaking clutch plates, there's a couple of possible reasons - jim senegal suggests using fsr450 springs (heavier). other reasons could be worn out friction 'fingers' leave much gap and hammer away at basket fingers, and using friction plates that have worn too thin.... if you break a plate, the plate pieces will migrate to the lowest spot in the case, which is under your shift selector scorpion - and you will not be able to shift down......

i'm sure there's more questions, but these are the ones i keep seeing come up..