Jakobi

Super Moderator

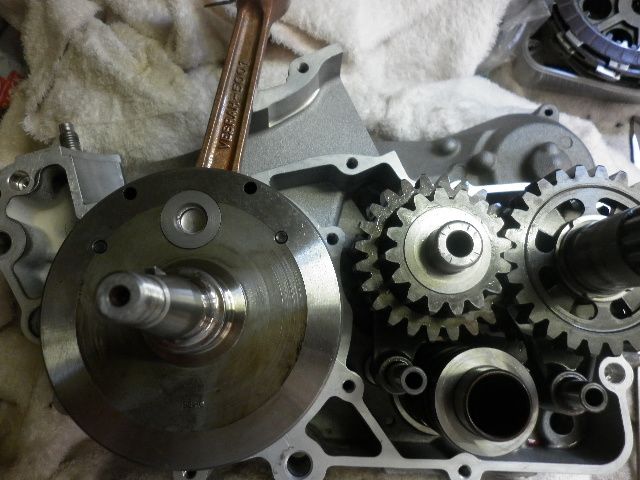

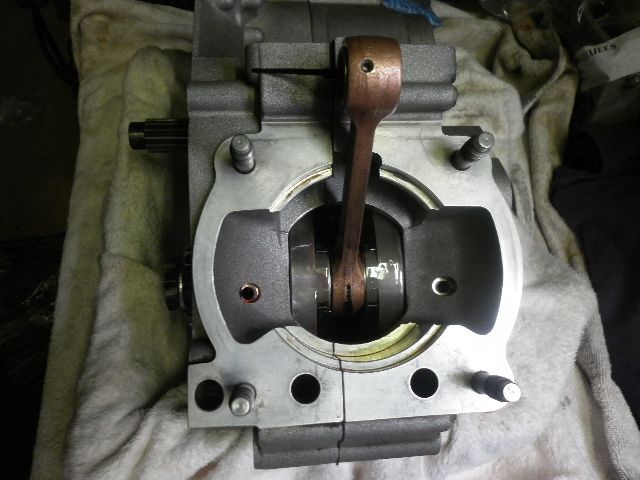

Finished work. Went past the ice factory and picked up a kilo and a half of pellets for $7. Past the bike shop and picked up the crank which went straight on the ice. It was a 45min trip home and I was all ready to install the crank. Then.. old man challenge decided to play his hand again.

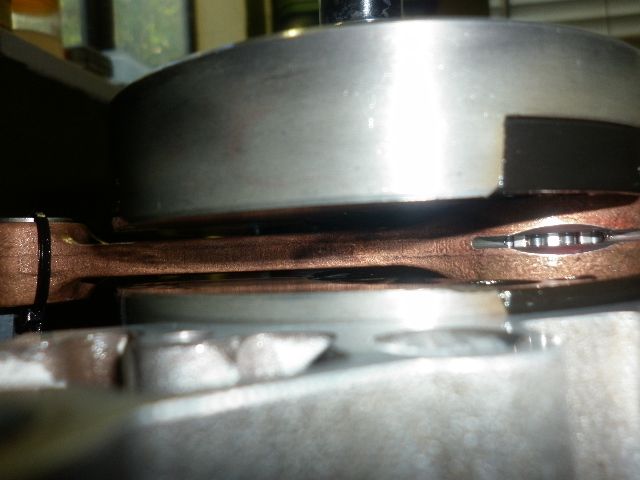

I removed the gasket from the spares and its torn. It didn't tear when I just pulled it out. It appears to have just sheered away along its natural grain. Needless to say its only good for the bin now. Scottys dirt bike spares are shipping me one up express which will save me, but tomorrows a public holiday and I'm at the other end of the country. It could be 3 days until I see it. The dry ice won't last that long so I'll be back to square one again. Not much more I can do but laugh about it. Wasted time and money. I guess I'll spend the spare time enjoying the PH, and the rest getting the top end setup (ring end gaps, deglaze bore, refit the pv, etc).

I removed the gasket from the spares and its torn. It didn't tear when I just pulled it out. It appears to have just sheered away along its natural grain. Needless to say its only good for the bin now. Scottys dirt bike spares are shipping me one up express which will save me, but tomorrows a public holiday and I'm at the other end of the country. It could be 3 days until I see it. The dry ice won't last that long so I'll be back to square one again. Not much more I can do but laugh about it. Wasted time and money. I guess I'll spend the spare time enjoying the PH, and the rest getting the top end setup (ring end gaps, deglaze bore, refit the pv, etc).