You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

APT SmartCarb

- Thread starter gasgasman

- Start date

Sure wish mine worked well. I have a crap load of time spent on it and it has become a $1000 conversation piece on my work bench.

Thought we agreed to buy it back from you, replace it, or work it out.

That article shows that they did 4 runs on the PWK, but never mentions if they actually made any changes to improve the running of the PWK. Who's to say their baseline was achieving max power?

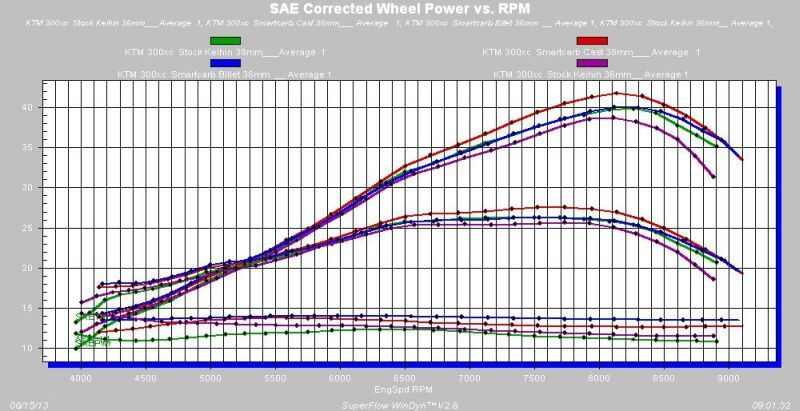

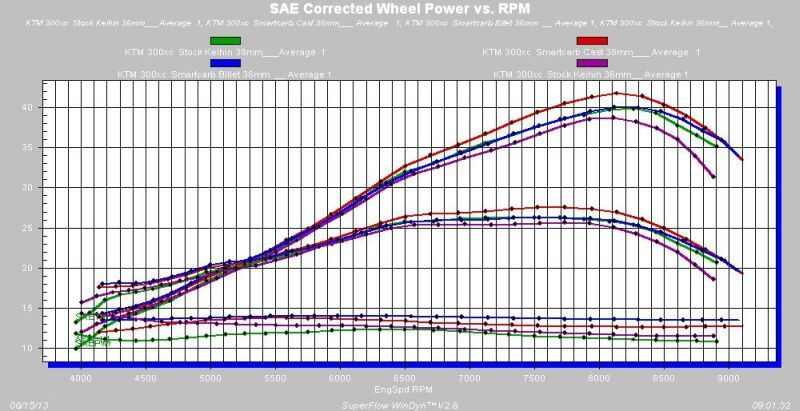

When we get ready to do testing like this, we set up the Keihin's for current conditions. We do the tuning primarily based off exhaust temps that we see for that day and peak HP. Idle, mid and top. For yesterday we were 75f. 30.12 in.hg steady and 67% humidity.

Stock 2009 KTM 300 XC

The 38mm ASII was set with a 170 main jet, N3CJ needle 5th clip position, 38 pilot, air screw 1.5 turns out.

The 36mm ASII was set 168 main jet N2ZW needle 4th clip position, 38 pilot, air screw 1.75 turns out. The SC's we used factory settings.

Power valve settings for all tests were; green spring half a turn in.

You will note that the 38mm Keihin builds almost identical power as the 36mm SC on this bike. I've been cautious with posting our own in house dyno charts but theses tests from yesterday show what DirtRider was saying. They also reported they were using KTM recommended settings and listed them in the article.

Last edited:

Rick

New member

Last time I checked my pipe does not have a EGT fitting....no dog in this fight for me...yet.....Isn't EGT monitor a advantage?

My buddy runs shifter carts and EGT monitoring plays a pretty vital role in jetting for him.

Please expand on this subject.....

THANKS

My buddy runs shifter carts and EGT monitoring plays a pretty vital role in jetting for him.

Please expand on this subject.....

THANKS

When we get ready to do testing like this, we set up the Keihin's for current conditions. We do the tuning primarily based off exhaust temps that we see for that day and peak HP. Idle, mid and top. For yesterday we were 75f. 30.12 in.hg steady and 67% humidity.

Stock 2009 KTM 300 XC

The 38mm ASII was set with a 170 main jet, N3CJ needle 5th clip position, 38 pilot, air screw 1.5 turns out.

The 36mm ASII was set 168 main jet N2ZW needle 4th clip position, 38 pilot, air screw 1.75 turns out. The SC's we used factory settings.

Power valve settings for all tests were; green spring half a turn in.

You will note that the 38mm Keihin builds almost identical power as the 36mm SC on this bike. I've been cautious with posting our own in house dyno charts but theses tests from yesterday show what DirtRider was saying. They also reported they were using KTM recommended settings and listed them in the article.

Jakobi

Super Moderator

Well I put another 150kms or so on mine. Many hours of riding various local terrain. I don't know what it is. I just can't get consistant results. Its like the carb is super sensitive to the bike (or air filter). The start of the ride it was good, very good. A bit in a went one click leaner and rode it like that all day. It ran like a champ most the day like this. Torquey off the bottom, but clean, and then quickly built into a nice crisp pull from mid to top. Then later this afternoon running it home it decides it wants to play burbly bottom end again, still alright torque but likes of 4 stroking and a definite lack in crispness to put it on the pipe. When you'd get it singing it felt like you had to work hard to keep it there too (hard when you're tired). So when I got home, just out of curiosity, I went one click leaner again. Low and behold it cleaned right up and felt good again. *scratches his head*. It was a dry dusty day, but I was either out front leading, or well at the back of the pack when the dust was out. I know the air filter is dirty but I doubt it will be totally caked. Whats up?

The "jetting" changing throughout the day makes me wonder if you have a sticking vent valve (if I understand the design correctly). I. E. you are not getting the air density correction that you should be getting as the conditions change throughout the day.

First it is two valves so both sticking is rather unlikely and second even if they'd stick it would cause a lower pressure within the float bowl meaning a lean condition.

I think I have two possible causes since the "one click leaner" solution doesn't point to float problems.

Unfortunately you have to remove the slide for a check.

1) Look at the flat part of the rod and check if is parallel to the slide surface; additionally try to turn the rod left and right and see how much deviation you can get - it should be very little. I got a faulty D-washer for indexing the rod with my R080 (almost 45? deviation in one direction) and have been making my own D-washers which are milled on the outside and use a set screw for perfect alignment with the rod. A rod that is not close to perfectly aligned will cause differences in fuel metering.

2) Take a flat blade screwdriver and try to operate/turn the clicker mechanism on top of the slide. There should be no free play in the adjuster, but a solid feel against the locking mechanism. If there is free play, vibration can move the adjuster/rod enough to cause fueling inconsistencies. If your mechanism is still working you can try to screw in the small black set screw on top of the adjuster. This should tighten up the free play - if not, it's broken like has been discussed in this thread already.

Have fun

Michael

Gasgasogeros

New member

if i see corect the dyno chart of sc give 5hp more from keihin pwk this can have with exhaust very easy doma can add more hp or try tillotson carb with hi end low abjust on the size of carb for easy abjust

Jakobi

Super Moderator

Michael has the answers, as always! You're the man!

I can tell you right now from memory that there is some definite play in the D washer. Not 45 degrees, but enough that the MR can turn a bit to each side. I know this because I wondered about it when I had the MR out for the lapping. Thought to myself "thats a bit of a sloppy finish". Issue being I don't have access to milling machinery to make up my own. Its very possible it has rotated a bit during running, especially after making an adjustment.

I'll also double check the clicker, but am pretty confident its firm in its engagement from one click to the next. I've already been through all of its parts with it having faint, barely feelable clicks, and poor engagement initially.

For what its worth, the air filter has its fair share of dust caked to it too.

I can tell you right now from memory that there is some definite play in the D washer. Not 45 degrees, but enough that the MR can turn a bit to each side. I know this because I wondered about it when I had the MR out for the lapping. Thought to myself "thats a bit of a sloppy finish". Issue being I don't have access to milling machinery to make up my own. Its very possible it has rotated a bit during running, especially after making an adjustment.

I'll also double check the clicker, but am pretty confident its firm in its engagement from one click to the next. I've already been through all of its parts with it having faint, barely feelable clicks, and poor engagement initially.

For what its worth, the air filter has its fair share of dust caked to it too.

I can tell you right now from memory that there is some definite play in the D washer. Not 45 degrees, but enough that the MR can turn a bit to each side. I know this because I wondered about it when I had the MR out for the lapping. Thought to myself "thats a bit of a sloppy finish". Issue being I don't have access to milling machinery to make up my own. Its very possible it has rotated a bit during running, especially after making an adjustment.

I asked Corey about the acceptable deviation, but never got an answer. If you look at your local (or mailorder) hobby store (for RC planes,cars, ...) you probably find a set collar with just the perfect dimensions - you need 3mm ID/8mm OD (for the R080 rod, A100 is smaller ID) and then have to grind/file the flat part. Do I have your e-mail address? I can mail you a pic of my modified rod with collar.

Michael

Last edited:

Last time I checked my pipe does not have a EGT fitting....no dog in this fight for me...yet.....Isn't EGT monitor a advantage?

My buddy runs shifter carts and EGT monitoring plays a pretty vital role in jetting for him.

Please expand on this subject.....

THANKS

Reading EGTs is an advantage for accurate tuning, but only if you know what those numbers mean according to piston wash, plug color and the overall health of the piston on your engine anyway.The only way to give the PWK it's best fighting chance is to jet it for safe best torque and HP for the conditions on the day of the testing. The way to do that is to run dyno tests and look for best performance along with proper EGT's to know you have the Keihin dialed in for that day.

Because the SC is always compensating for local conditions this way we get the best comparison.

Last edited:

arminhammer

New member

Customer service has not been the problem. The promise of a bolt on perfectly jetted carb that has been anything but is the problem.Thought we agreed to buy it back from you, replace it, or work it out.

I can jet a carb perfectly well. I do it every day for my customers. The idea was that I would never have to mess with mine no matter where I rode.

I,like you don't always have time for my toys. I'm not pissed off, just disappointed.

Motosportz

New member

twowheels

Active member

Is it not what you said or did you change your mind?

Motosportz

New member

Is it not what you said or did you change your mind?

I said it. But was not asked to be quoted on their web site, and was not treated nice by them so don't care to participate. Not a big deal just don't want the association. The APT I tried was fine and I was honest in my reporting which can be found here and at Cafehusky. I moved on and do not endorse this product now as I found better products and support. No big deal. Was looking up something else, saw my quote there and found it funny after the owner publicly trashed me and called me names.

I said it. But was not asked to be quoted on their web site, and was not treated nice by them so don't care to participate. Not a big deal just don't want the association. The APT I tried was fine and I was honest in my reporting which can be found here and at Cafehusky. I moved on and do not endorse this product now as I found better products and support. No big deal. Was looking up something else, saw my quote there and found it funny after the owner publicly trashed me and called me names.

Quote will be removed. Kelly no one trashed you or called you names, publicly or otherwise, I appreciated your review then and I appreciate it now, it was Cafehusky's unwillingness to post my answers to peoples questions regarding the SC. I'm sure you're way past it, as am I, but the conversation is all written down in the forum threads so you may want to keep your story straight.

Motosportz

New member

Quote will be removed. Kelly no one trashed you or called you names, publicly or otherwise, I appreciated your review then and I appreciate it now, it was Cafehusky's unwillingness to post my answers to peoples questions regarding the SC. I'm sure you're way past it, as am I, but the conversation is all written down in the forum threads so you may want to keep your story straight.

sounds good, no problem nor am I looking to stir the crap, all good. Thanks.

Kelly

Jakobi

Super Moderator

Customer service has not been the problem. The promise of a bolt on perfectly jetted carb that has been anything but is the problem.

I can jet a carb perfectly well. I do it every day for my customers. The idea was that I would never have to mess with mine no matter where I rode.

I,like you don't always have time for my toys. I'm not pissed off, just disappointed.

Well said.

Just curious, I dont know if you have covered it already and I missed it or not, but could you elaborate on where you felt the Smart Carb was falling short? Which parts of it aren't meeting your expectations?

Jakobi

Super Moderator

APT Sold...

That one didn't work for me.. Try this. Oh by my the way...... APT looks to be sold.... Hmmmmm

http://www.marketwatch.com/m/story/fb0886f1-e238-4e8d-9373-9f564e7ad205

That one didn't work for me.. Try this. Oh by my the way...... APT looks to be sold.... Hmmmmm

http://www.marketwatch.com/m/story/fb0886f1-e238-4e8d-9373-9f564e7ad205

Similar threads

- Replies

- 2

- Views

- 633

- Replies

- 17

- Views

- 441

- Replies

- 1

- Views

- 223